Grinding operations pose significant hazards in industrial environments, from flying wheel fragments to abrasive particle exposure and contact injuries. The Occupational Safety and Health Administration has established comprehensive regulations under 29 CFR 1910.215 to protect workers who operate or work near abrasive wheel machinery. These OSHA grinder regulations cover every critical aspect of grinder safety, including machine guarding specifications, flange requirements, mounting procedures, and inspection protocols. Understanding and implementing these standards is not optional for employers—it is a legal requirement that, when ignored, can result in serious workplace injuries, regulatory penalties, and potential liability exposure.

This guide breaks down the essential OSHA grinder regulations into actionable requirements you can apply immediately in your workplace. Whether you operate bench grinders, surface grinders, cylindrical grinders, or cutting-off machines, the principles outlined here will help you achieve compliance and, more importantly, protect your workers from the inherent dangers of abrasive wheel operations. The regulatory framework addresses multiple machine categories, each with specific requirements tailored to its operational characteristics and associated risk profile. By mastering these requirements, you create a safer work environment while satisfying your legal obligations under federal occupational safety law.

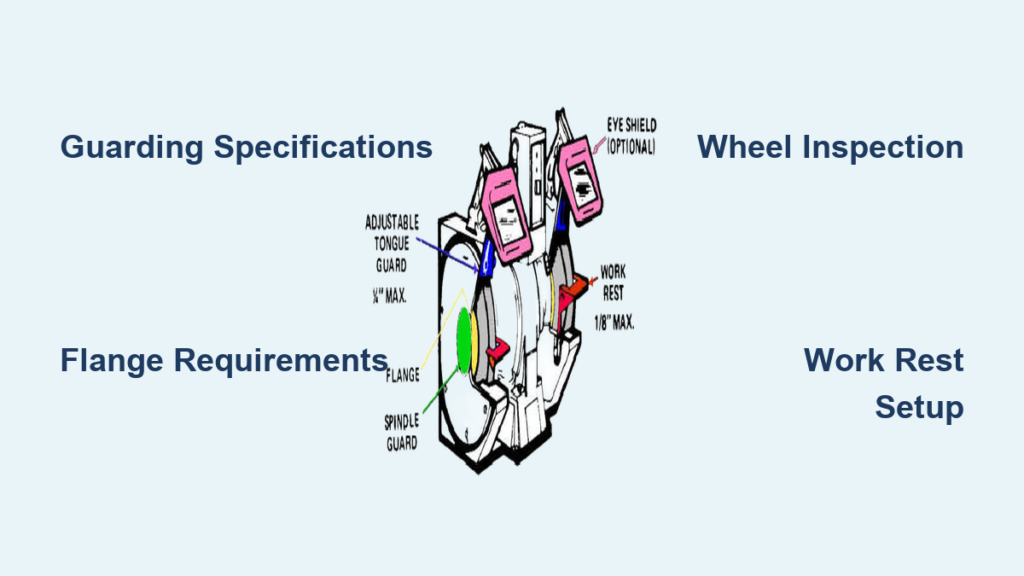

Abrasive Wheel Machine Guarding Specifications

Every grinder must operate with safety guards meeting precise OSHA specifications that prevent flying debris and contain wheel fragments during breakage. These guards must cover spindle ends, nuts, and flange projections while maintaining proper alignment with the wheel. The fastenings securing the guard must exceed the guard’s strength to ensure it remains in place under stress conditions. For bench and floor stand machines, the angular exposure of the grinding wheel must not exceed 90° or one-fourth of the wheel periphery—whichever is less restrictive—with exposure beginning at a point no higher than 65° above the horizontal plane of the wheel spindle.

When work requires contact with the wheel below the spindle’s horizontal plane, exposure may increase to 125°. Cylindrical grinders permit up to 180° exposure beginning at 65° above the spindle plane, while surface grinders and cutting-off machines using the wheel periphery are limited to 150° exposure beginning at 15° below the spindle plane. Swing frame grinders and automatic snagging machines both allow 180° exposure but require the top half of the wheel to remain enclosed during operation.

Cup Wheel Protection Standards

Cup wheels of Types 6 and 11 require specific protection measures including standard safety guards, band-type guards, or special revolving cup guards that rotate with the wheel. Revolving cup guards must be constructed from steel or equally strong material and enclose the wheel sides upward from the back for one-third of the wheel thickness. Critical clearance between the wheel side and guard must never exceed one-sixteenth inch to prevent material intrusion while allowing normal operation. These specialized guards must conform to all mounting requirements specified in the OSHA grinder regulations to ensure maximum operator protection.

Guard Material Requirements by Operating Speed

Material requirements for safety guards depend directly on grinding wheel operating speed. For wheels operating at 8,000 surface feet per minute or less, cast iron or malleable iron guards meeting equivalent strength specifications are acceptable. When speeds exceed 8,000 surface feet per minute up to 16,000 surface feet per minute, guards must be constructed from cast steel or structural steel with dimensions meeting regulatory specifications.

Cutting-off wheels have specific guard requirements based on size. For wheels 16 inches in diameter and smaller operating at speeds not exceeding 16,000 surface feet per minute, cast iron or malleable iron guards meeting dimensional specifications are required. Larger cutting-off wheels (over 16 inches) operating at speeds up to 14,200 surface feet per minute require guards meeting different specifications appropriate for their size.

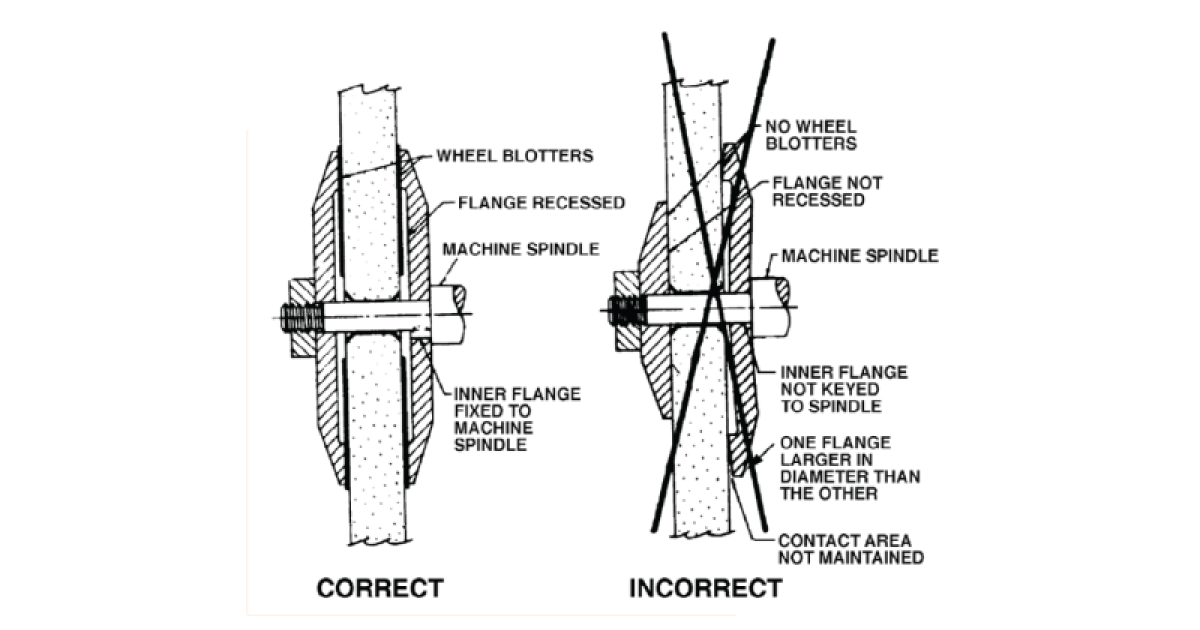

Flange Requirements for Proper Wheel Mounting

All abrasive wheels must mount between flanges meeting minimum dimensional requirements to ensure adequate contact surface and pressure distribution. Standard flanges must not be less than one-third the wheel diameter, though exceptions exist for specialized wheels. Type 1 cutting-off wheels require mounting between properly relieved flanges with matching bearing surfaces of at least one-fourth the wheel diameter. Type 27A cutting-off wheels use flat, non-relieved flanges that must be at least one-fourth the wheel diameter but may be less than one-third.

Flange Dimensional Accuracy and Maintenance

Flanges must maintain dimensional accuracy and good balance to ensure smooth wheel operation and even pressure distribution. All flange surfaces must be free from roughness and sharp edges that could damage wheels or create injury hazards. Both mounting flanges must be identical in diameter with equal bearing surfaces to ensure symmetric mounting forces. When bearing surfaces become worn, warped, or damaged, they should be trued or refaced to restore proper geometry while maintaining specified relief and rigidity.

Recess and Undercut Specifications

Straight relieved flanges must recess at least one-sixteenth inch on the side next to the wheel for the distance specified in regulatory tables. This recess prevents flange bearing near the arbor hole, reducing stress concentrations that could cause wheel cracking. Straight flanges of adaptor or sleeve type must undercut so there’s no bearing on wheel sides within one-eighth inch of the arbor hole. These geometric configurations distribute pressure evenly across the wheel face, preventing localized stress points that lead to wheel failure.

Work Rest Setup for Offhand Grinding Machines

On offhand grinding machines, work rests must provide rigid support for workpieces during operations. These rests must be adjustable to compensate for wheel wear as diameter decreases during use. Critically, work rests must maintain a maximum opening of one-eighth inch between the rest and wheel surface to prevent workpieces from jamming between the wheel and rest—a common cause of wheel breakage and serious operator injury.

Following each adjustment, the work rest must be securely clamped in position. Never adjust work rest position while the wheel is in motion, as contact between the wheel and adjustable rest could cause wheel damage or injury. Establishing clear procedures requiring machines to stop completely before work rest adjustment is essential for workplace safety compliance under OSHA grinder regulations.

Wheel Inspection and Ring Testing Procedures

Immediately before mounting, all wheels require close inspection and ring testing to detect damage from transit, storage, or handling. The spindle speed must be verified against the maximum operating speed marked on the wheel—operating beyond design limits causes catastrophic wheel failures. To perform the ring test, tap wheels gently with a light nonmetallic implement: use a screwdriver handle for lighter wheels or wooden mallet for heavier ones.

Ring Test Technique and Interpretation

Wheels must be dry and free from sawdust during ring testing, as moisture or debris deadens sound and masks cracks. Tap the wheel about 45° on each side of the vertical centerline approximately 1-2 inches from the periphery, then rotate 45° and repeat. A sound wheel produces a clear metallic tone, while a cracked wheel creates a dead sound without characteristic ring. Note that organic bonded wheels don’t emit the same clear metallic ring as vitrified and silicate wheels—operators must recognize these differences during inspection.

Proper Wheel Mounting Techniques

Grinding wheels must fit freely on the spindle and remain free under all grinding conditions. Achieving proper clearance requires machine spindles manufactured to nominal size plus zero minus .002 inch tolerance, with wheel holes suitably oversized to accommodate operating heat and pressure. All contact surfaces of wheels, blotters, and flanges must be flat and free of foreign matter before mounting—any debris, oil, or contamination interferes with pressure distribution and potentially causes wheel failure.

Blotter Requirements and Multiple Wheel Mounting

Blotters (compressible washers) must always be used between flanges and abrasive wheel surfaces to ensure uniform pressure distribution across the wheel face. These critical components prevent localized stress concentrations that could lead to wheel breakage. When mounting multiple wheels between a single set of flanges, wheels may be cemented together or separated by specially designed spacers that equal flange diameter with matching bearing surfaces.

Regulatory Compliance Implementation Strategies

The OSHA grinder regulations establish minimum safety requirements for machine construction, guard design, wheel mounting, and operational procedures. Compliance requires attention to multiple interconnected elements—from safety guard characteristics to wheel inspection protocols. Certain equipment is explicitly excluded from these regulations, including natural sandstone wheels and metal, wooden, cloth, or paper discs with abrasive surfaces, as their hazard profiles differ significantly from conventional abrasive wheels.

Employers must ensure grinding operations comply with these standards through proper equipment provision, worker training in safe procedures, and equipment maintenance. Implementing a comprehensive grinder safety program starts with understanding OSHA grinder regulations and developing workplace-specific procedures addressing each requirement. Regular audits of grinding operations help identify potential violations before they result in citations or, more critically, before they cause harm to your workforce.

Final compliance tip: Document all grinder safety inspections, maintenance activities, and employee training sessions. This documentation serves as evidence of your commitment to safety and can protect your business during OSHA inspections. Remember that adhering to OSHA grinder regulations isn’t just about avoiding penalties—it’s about preventing life-altering injuries and creating a workplace where safety is prioritized above all else.