You’ve just finished processing a large batch of venison when your grinder suddenly starts making strange noises. As you disassemble it for inspection, you realize you can’t even identify which component is causing the problem. Knowing precise meat grinder parts names isn’t just technical jargon—it’s essential for ordering correct replacements, performing efficient repairs, and maintaining optimal grinding performance. Whether you’re using a compact #5 grinder for occasional home use or a heavy-duty #32 commercial unit, each component plays a specific role in the grinding mechanism.

The meat grinding process relies on precisely engineered components working together in sequence. Meat enters through the hopper, where the auger pulls it toward the cutting assembly. The rotating knife slices against the stationary grinding plate, forcing meat through the plate’s holes at your desired consistency. Retaining rings hold everything in place under pressure, while seals prevent grease leakage. When you understand meat grinder parts names and functions, you save time during repairs, avoid costly compatibility mistakes, and extend your equipment’s lifespan through proper maintenance.

Why Your Grinder Knife Direction Matters for Proper Cutting

The grinder knife, sometimes called the cutting blade, performs the actual meat-slicing action within the grinding head. This critical component rotates against the stationary grinding plate, continuously cutting meat as the auger pushes material forward. A dull or reversed knife produces ragged cuts, strains your motor, and creates inconsistent texture in ground meat. Most manufacturers recommend replacing both the knife and grinding plate simultaneously—even when only one shows visible wear—to maintain proper cutting geometry.

Installation direction is critical: the sharp edge must face the grinding plate. Reversing the knife eliminates its cutting action entirely, resulting in meat being merely pushed through rather than properly cut. When selecting replacement knives, verify both model number compatibility and physical specifications. The universal grinder knife serving models #1224, 1182, 1113, and 822 costs $11.99 and measures 8.8mm thick with a 55.6mm diameter. For the #8 MightyBite Grinder model 1158, the specific one-way stainless steel knife costs $13.99 and features precision-engineered cutting geometry optimized for that unit.

How to Identify Your Specific Grinder Knife Type

Look for these key identifiers when replacing your knife:

– Thickness measurement: Most range from 8-9mm

– Diameter specification: Typically between 55-60mm

– Mounting hole pattern: Must match your auger’s drive stud

– Cutting edge orientation: One-way designs have clear directional markings

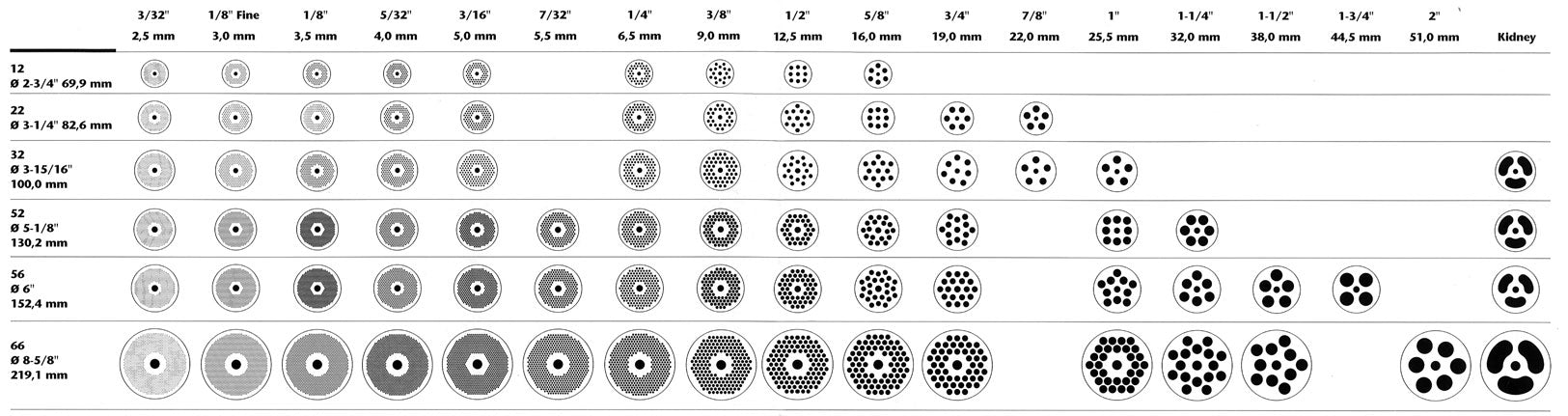

Coarse vs. Medium Grinding Plates: Which Hole Size You Need

Grinding plates, also called grinding discs, determine your final meat texture through their hole diameter. These perforated metal discs work with the knife—the knife cuts while the plate’s holes control particle size. Using a worn plate produces uneven texture, while selecting the wrong hole size creates frustration and wasted meat. Understanding meat grinder parts names for plates prevents these common mistakes.

Coarse grinding plates feature 10mm (3/8 inch) holes ideal for first grind operations, chorizo, and linguisa. The coarse plate for #1113, 1224, and 1182 meat grinders costs $9.99 and measures 2-3/8 inches in diameter. Medium plates offer versatility: 6mm plates produce medium-fine texture priced at $27.00 for TC-8, $28.00 for TC-12, and $29.00 for TC-22 models. The slightly coarser 8mm plates maintain better throughput while still delivering consistent results.

Troubleshooting Plate-Related Grinding Problems

When your ground meat appears inconsistent or the grinder strains:

– Ragged edges on meat particles: Indicates dull knife or worn plate holes

– Meat smearing instead of cutting: Likely caused by reversed knife installation

– Reduced throughput speed: Check for rounded hole edges on the plate

– Meat backing up in hopper: Verify proper plate orientation (smooth side toward knife)

Auger Drive Gear Assembly: The Hidden Transmission Component

The auger serves as the meat transportation system, generating forward thrust that pulls meat from the hopper toward the cutting assembly. This helical screw component experiences significant wear over time, particularly when processing meat with connective tissue. Replacement augers range from $132.99 for SL-8 models to $185.99 for the JQ-58 combination unit.

Drive gears often fail before the auger itself. The complete auger drive gear assembly for #1113 and #1224 meat grinders costs just $3.99 and includes multiple critical components: drive gear, silicone washer, plastic washer, screw, and steel washer. Proper assembly orientation is crucial—the silicone washer must seat correctly, and the gear’s notch must align with the corresponding component. Incorrect installation causes premature wear or complete drive failure.

Signs Your Drive Components Need Replacement

Watch for these warning signs indicating drive system problems:

– Unusual grinding noises during operation

– Slipping transmission where motor runs but auger doesn’t turn

– Reduced throughput requiring excessive force to push meat through

– Visible grease leakage around the auger shaft area

Stainless Retaining Rings: Preventing Costly Assembly Failures

Retaining rings secure the entire cutting assembly within the grinder head, preventing components from dislodging under pressure. These threaded rings must withstand significant clamping force while remaining removable for cleaning. Stainless steel rings provide superior corrosion resistance given constant exposure to meat juices.

The stainless retaining ring for #8 BigBite Grinder models 1779 and 1784 (also compatible with DualGrinder 1472) costs $34.99. The corresponding #5 BigBite ring for models 777, 777A, and 1777 costs $31.99. Both follow identical retention mechanisms despite the size difference. Cross-threading during installation damages both the ring and grinder head’s internal threads, potentially requiring expensive head replacement.

Proper Retaining Ring Maintenance Procedure

Follow these steps for trouble-free ring maintenance:

1. Clean threads thoroughly after each use to prevent meat buildup

2. Apply food-safe lubricant sparingly to prevent galling

3. Hand-tighten only—overtightening can strip threads

4. Inspect regularly for corrosion or thread damage

5. Replace immediately if threads show significant wear

Grease Seals vs. Gaskets: Critical Distinctions in Sealing Components

Sealing components prevent grease leakage from the gearbox while maintaining proper lubrication. These relatively inexpensive parts cause significant problems when they fail—a small grease leak quickly depletes gearbox lubricant, while leaked grease contaminates meat products. Understanding meat grinder parts names for seals prevents costly transmission damage.

The grease seal for BigBite grinder models 1777-1782 costs $8.99 and prevents lubricating grease from escaping through the hub. Symptoms of failure include visible grease accumulation around the hub or mysteriously reduced grease levels. The replacement gasket for 2017+ BigBite models costs $3.99 and fits between critical mating surfaces to prevent juice leakage. Specialized gaskets like the #5 curved rubber pad ($25.49) require precise model and date identification—grinders made before September 2011 need a different design.

How to Diagnose Seal and Gasket Failures

Identify failing sealing components by checking for:

– Grease accumulation around the grinder hub or motor area

– Visible oil leakage from seam lines between components

– Reduced grinding efficiency caused by internal lubrication loss

– Meat contamination from leaked grease or oil

Grinder Head Compatibility: Why Production Year Matters

The grinder head houses the entire cutting assembly and connects to the motor. Replacement heads become necessary when internal threads strip or chambers become damaged. These major components represent significant investments—the #22 BigBite Grinder Head for 2006 models costs $121.49, while the #32 version runs $191.99.

Production year compatibility creates confusion for many owners. LEM Products specifically notes that BigBite grinder heads from 2006 require different part numbers than 2007 and later versions, despite appearing identical. The #32 grinder head for 2006 models uses a different part number than 2007+ versions (01001029). Similarly, #22 heads from 2006 differ from 2007+ versions (01001025). When ordering heads, always verify both model number AND production year.

Critical Head Identification Tips

Before ordering a replacement head:

– Check your owner’s manual for exact model specifications

– Locate manufacturing date codes on the original head

– Contact manufacturer support with your serial number

– Never assume compatibility based on visual appearance alone

Meat Stomper Safety: Why You Need the Correct Size

The meat stomper (pusher) serves dual safety and efficiency functions during processing. This essential tool pushes meat into the grinder head while keeping hands safely away from moving components. Regular stomper use prevents hand fatigue during large jobs and significantly reduces injury risk—making it essential rather than optional.

Stomper compatibility varies by head diameter. The meat stomper for #5 grinders including model 1777 costs $7.99 and features poly construction. However, owners of #8 575 Watt Countertop Grinders must order SKU #01007004 due to larger head diameter. Using the wrong size stomper creates dangerous gaps where fingers could slip toward moving parts.

Grinder Size Classification: The Key to Part Compatibility

Meat grinders use size classifications (5, 8, 12, 22, 32) that indicate capacity and physical dimensions. Parts must match your grinder’s size classification—a #5 grinder cannot use #8 components. Understanding meat grinder parts names within this classification system prevents ordering errors.

The #5 BigBite series (models 777, 777A, 1777) uses specific components including the #5 stainless retaining ring ($31.99) and curved rubber gasket ($25.49 for post-September 2011 models). The #8 BigBite series (models 1779, 1784) uses the #8 stainless retaining ring ($34.99). Multi-model compatible parts simplify inventory—the universal grinder knife serving #1224, 1182, 1113, and 822 models costs $11.99.

Critical Maintenance Schedule for Long Grinder Life

Establish regular inspection routines to extend equipment life and prevent failures during critical processing. Cutting components like knives and plates should be inspected weekly during regular use. Dull knives produce ragged cuts and increase motor strain. When inspecting plates, look for rounded hole edges and metal deformation indicating replacement is necessary.

Seals and gaskets require monthly inspection for early problem detection. Replace these components at first sign of leakage, cracking, or compression set. Drive components like augers and gears typically last several years but may need earlier replacement when processing challenging materials. Retaining rings need annual thread inspection—cross-threading during installation is a common cause of unexpected part failure.

Understanding meat grinder parts names and their specific functions empowers you to maintain equipment properly, order correct replacements, and perform repairs confidently. The investment in quality replacement parts and regular maintenance pays dividends through consistent grinding performance, extended equipment life, and reduced total cost of ownership. When you can accurately identify each component, you transform from a frustrated user into a knowledgeable operator who keeps their grinder running smoothly for years to come.