Your Magic Bullet blender suddenly stopped working mid-smoothie, and now you’re wondering if it’s worth fixing or time to toss it. Before you give up on your compact kitchen companion, know this: most Magic Bullet failures are surprisingly simple to diagnose and repair with the right approach. This guide walks you through everything from identifying your specific model to replacing worn parts and maintaining peak performance.

The Magic Bullet is a compact blender sold in over 50 countries by Homeland Housewares, designed to replace larger blenders, food processors, and electric juicers in a more compact form factor. With proper repair techniques, even 20-year-old units can be restored to full functionality using affordable replacement parts. You’ll learn exactly which problems you can fix yourself and when it’s time to consider replacement.

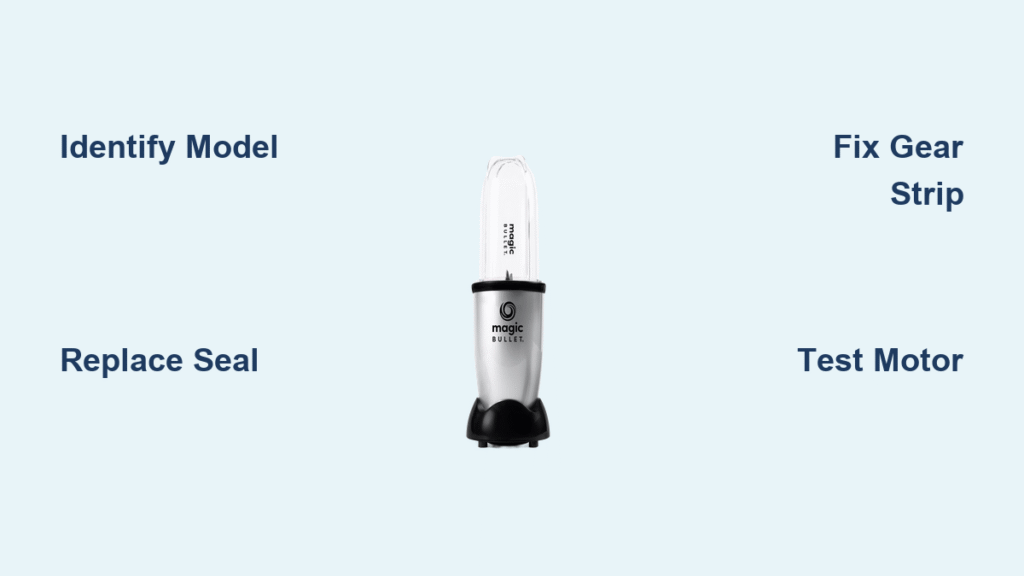

Identify Your Magic Bullet Model Before Repair

Check Model Number Location and Compatibility

Flip your Magic Bullet base upside down to find the model number on a small white sticker near the power cord. The most repairable model is the MB1001 (250W), which accepts universal replacement parts. MB1001B variants use identical components. Before attempting any magic bullet blender repair, confirm you have a standard 250W Magic Bullet rather than incompatible variants.

Models That Won’t Benefit From Standard Repairs

Don’t waste time on these variants—they require proprietary parts that aren’t interchangeable:

– Mini Magic Bullet

– Baby Bullet

– Any NutriBullet (including 1200W and rx)

– NutriNinja variants

Quick Compatibility Verification Test

Count the fins on your blade assembly. 250W Magic Bullet models feature three fins that lock into the base. If your unit has a different fin count or uses push-down rather than twist-lock mechanisms, you’ll need model-specific parts. The standard Magic Bullet’s name derives from the bullet-shaped curve of the blending cups, which helps identify authentic units.

Diagnose Your Specific Magic Bullet Problem

Motor Completely Dead: No Power Response

When your Magic Bullet shows zero response—no lights, no sound, no movement—the issue typically stems from electrical failure. First, check your outlet with another device, then inspect the power cord for visible damage. For internal fuse failure, you’ll need to disassemble the base. This is common in older units where the motor retains heat that can cause component failure.

Blade Won’t Spin Despite Motor Humming

If the motor hums but blades remain stationary, your gear assembly has likely stripped. This common failure occurs when ice or frozen ingredients overload the motor. The plastic drive gear inside the base strips its teeth, preventing power transfer to the blades. This is one of the most frequent issues requiring magic bullet blender repair.

Leaking Around Blade Assembly

Black liquid seeping from under your cup indicates seal failure. The rubber O-ring gasket beneath the blade assembly deteriorates over time, especially with frequent dishwasher cycles. This creates gaps where liquids escape during blending. Immediate replacement prevents further damage to internal components.

Essential Repair Tools for Magic Bullet Fixes

Basic Tool Requirements

You’ll need just three essential tools for most repairs:

– Phillips #1 screwdriver: Removes base screws hidden under rubber feet

– 6-in-1 screwdriver: Handles various screw sizes during disassembly

– Channellock groove joint pliers: Grips stuck components without damage

Optional but Helpful Accessories

A magnetic parts tray prevents screw loss, while a headlamp illuminates tight spaces inside the base. Needle-nose pliers help remove tiny components during gear assembly replacement. These tools make the magic bullet blender repair process significantly easier and prevent losing small parts.

Disassemble Magic Bullet Base Safely

Critical Safety Precautions

Unplug your Magic Bullet and let it cool for 30 minutes if recently used. The motor retains heat that can cause burns during handling. Never force components apart—this creates additional damage that complicates your repair.

Step-by-Step Disassembly Process

- Remove rubber feet: Gently pry off four rubber feet on base bottom with flathead screwdriver

- Extract hidden screws: Remove four Phillips screws revealed under feet

- Separate housing halves: Carefully pry base halves apart using plastic tool

- Access motor assembly: Lift motor unit from bottom housing section

- Document wire positions: Take photos before disconnecting any wires

Gear Assembly Warning

The gear assembly connects to the motor shaft with a stubborn retaining clip. This component earns its reputation as “a royal PITA to remove”—expect significant resistance. Many users damage the housing during this step, so proceed with patience.

Replace Key Magic Bullet Components

Blade Assembly Replacement Procedure

Both cross blade and mono-wing blade replacements fit 250W Magic Bullet models perfectly. The cross blade handles most blending tasks, while the mono-wing blade excels at grinding spices and coffee. Installation takes just minutes:

- Remove old blade: Unscrew counterclockwise from cup

- Clean threads: Remove old seal residue with warm soapy water

- Install new seal: Press replacement O-ring into blade base groove

- Thread new blade: Screw clockwise until snug—avoid over-tightening

- Test fit: Attach to base and check for smooth rotation

Seal Replacement Technique

Spare O-ring gaskets prevent future leaks. Install by stretching gasket over blade base lip, ensuring it seats completely in the groove. A properly installed seal lies flat with no twists or kinks. This simple $2 fix resolves most leakage problems.

Fix Magic Bullet Motor Issues

Internal Fuse Testing

Use a multimeter to test continuity across the fuse located on the motor’s circuit board. No continuity indicates a blown fuse requiring replacement. This repair requires soldering skills—consider professional help if you’re not experienced with electronics.

Gear Assembly Rebuild

Stripped drive gears need complete replacement. The plastic gear press-fits onto the motor shaft but removal often destroys the gear. Order a replacement gear assembly rather than attempting to salvage the original. This is the most common repair needed for Magic Bullet blenders that hum but don’t spin.

Prevent Future Magic Bullet Problems

Daily Maintenance Routine

Rinse blade assembly immediately after each use. Dried food particles create resistance that stresses motor and gears. Never submerge the base unit—wipe clean with a damp cloth only. This simple habit extends your blender’s lifespan significantly.

Usage Best Practices

- Fill to max line: Overfilling stresses the motor

- Pulse technique: Use short pulses for tough ingredients

- Ice crushing: Add liquid first, then ice gradually

- Rest periods: Allow 2-minute cooling between extended blending sessions

Upgrade with Premium Replacement Parts

haffy Replacement Kit Benefits

The $9.99 haffy kit includes cross blade, mono-wing blade, and two spare seals—everything needed to restore 20-year-old units. Made with stainless steel blades that remain sharp through thousands of uses, this kit provides professional-grade performance at a fraction of replacement cost.

Performance Verification

After installation, test with water first. Successful operation produces a smooth vortex without vibration or unusual noise. Leaks indicate an improperly seated seal—disassemble and reinstall. Users report enhanced spice grinding performance exceeding dedicated spice grinders.

Magic Bullet Model Compatibility Guide

Verified Compatible Models

- Magic Bullet 250W (MB1001)

- Magic Bullet MB1001B

- Magic Bullet To Go 250W

- Standard Magic Bullet (3-fin design)

Cross-Reference Checklist

Before ordering parts, verify:

– [ ] Base shows 250W rating

– [ ] Three fins on blade assembly

– [ ] “Magic Bullet” branding (not NutriBullet)

– [ ] Twist-lock mechanism (not push-down operation)

When to Replace vs Repair Your Magic Bullet

Repair Recommended Scenarios

- Blade dullness: $10 part replacement

- Seal leaks: $2 O-ring fix

- Gear stripping: $15 gear assembly

Replace Entire Unit When

- Motor failure: $50+ repair exceeds new unit cost

- Cracked base housing: Structural integrity compromised

- Multiple component failure: Repair costs approach replacement price

Final Maintenance Checklist

Keep your Magic Bullet running smoothly with these weekly habits:

– Inspect seals: Look for cracks or deformation

– Clean blade assembly: Remove all food residue

– Check base vents: Clear dust buildup with compressed air

– Test operation: Run empty for 10 seconds to verify smooth operation

– Store properly: Keep blades covered to maintain sharpness

Your Magic Bullet can provide decades of reliable service with proper care and timely part replacement. The compact design that makes it convenient also makes repairs straightforward—most issues resolve with basic tools and affordable replacement parts. By following these magic bullet blender repair guidelines, you’ll save money while extending the life of your kitchen essential. Remember that simple maintenance prevents most common problems, keeping your blender ready for daily smoothies, sauces, and spice grinding tasks.