Few tools match the versatility of an angle grinder when you need to cut tile, remove rust, sharpen blades, or grind steel. This high-speed power tool becomes indispensable across workshops and construction sites, but its aggressive nature demands proper training before operation. When sparks fly and debris scatters at dangerous velocities, knowing how to operate a grinder safely separates professionals from those who risk serious injury. This guide delivers everything you need to confidently and safely use your angle grinder for various materials and applications.

Many beginners feel intimidated by the noise and power of angle grinders, yet with the right knowledge, this tool often becomes one of the most frequently reached-for items in any workshop. Mastering how to operate a grinder requires understanding three critical elements: comprehensive safety protocols, correct accessory selection, and proper application techniques. The key lies in respecting the equipment while developing the skills to control it effectively across different materials.

Essential PPE for Grinder Safety

Before you even think about how to operate a grinder, equip yourself with comprehensive personal protective equipment. This tool generates high-speed rotation, flying debris, sparks, and significant noise that demand serious protection. Safety goggles or a full-face shield are non-negotiable—you need protection against airborne particles traveling at dangerous velocities. A full-face shield provides superior protection compared to safety glasses alone, especially during grinding where debris trajectories are unpredictable.

Heavy-duty work gloves improve your grip while protecting hands from accidental contact with spinning discs or hot materials. Steel-toed boots guard against dropped materials that could cause serious foot injuries. A dust mask or respirator protects your lungs when working with materials that produce harmful dust like masonry or painted surfaces. Hearing protection is also advisable during extended operations, as angle grinders generate noise levels capable of causing hearing damage. Never operate a grinder without all appropriate PPE in place—shortcuts on protection can result in permanent injury.

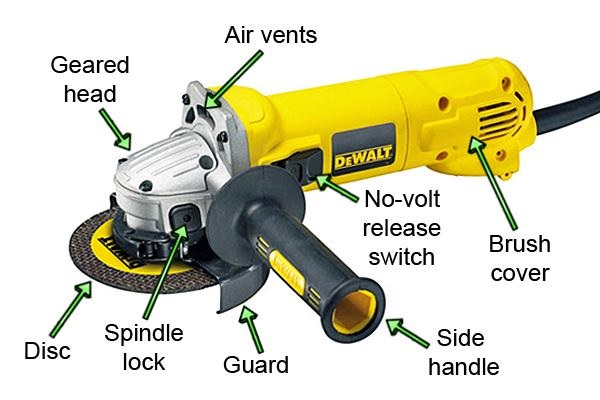

Key Grinder Components You Must Know

Understanding your grinder’s anatomy is fundamental to safe operation. The side handle provides essential grip control and can be positioned on either side to accommodate left-handed or right-handed users. Always verify the handle is firmly attached before operation, especially during demanding applications that generate significant resistance.

The safety guard represents the most critical protective component on your grinder. This shield protects you from sparks, debris, and potential disc shattering—never remove it under any circumstances. Guards adjust to position the open side away from your body, allowing sparks and debris to fall downward. Before beginning work, ensure the guard is correctly positioned and securely locked.

The disc performs the actual work of cutting, grinding, or polishing, mounting onto the tool’s spindle where a retaining flange or nut secures it. Proper mounting is essential—discs must sit completely flat against the spindle surface with the bore correctly aligned. Some discs are directional while others mount with either face up, so always consult manufacturer instructions.

Choose the Right Wheel or Disc for Your Task

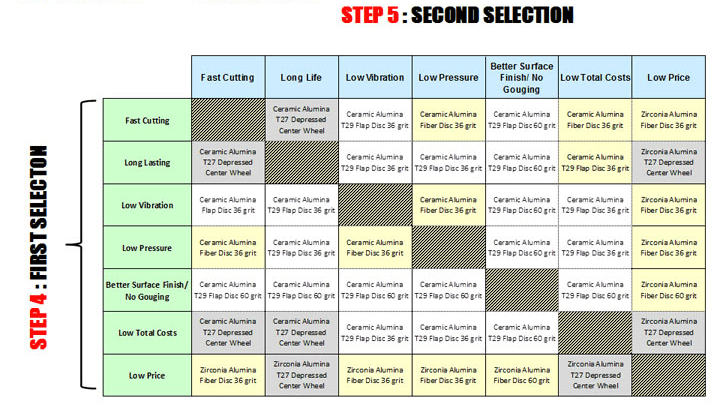

Selecting the appropriate disc dramatically affects both results and safety when learning how to operate a grinder. Cut-off wheels, designed primarily for cutting metal pieces including bars, tubes, and small sheet metal sections, come in various thicknesses. Thinner discs provide faster cutting action but increased shattering risk. These wheels excel at cutting out welds or shortening bolts.

Grinding wheels serve as all-purpose discs for metal work, handling weld cleanup, material removal, and surface shaping. These thicker wheels handle aggressive material removal rather than precision cutting. Flap discs provide significantly finer finishes than traditional grinding wheels with multiple grit options for different applications. Higher grit numbers indicate finer abrasive particles and smoother finishes.

Wire wheels rapidly remove rust from metal surfaces, with cup-shaped and wheel-shaped configurations serving different purposes. Paint stripping wheels made from poly-fiber materials offer gentler action less likely to scratch underlying surfaces, making them suitable for soft metals, wood, or fiberglass. For masonry applications, concrete grinding wheels or diamond wheels handle the extreme hardness of cement, stone, brick, and tile.

Prepare Your Grinder Before Starting

Before you learn how to operate a grinder safely, disconnect it from its power source—unplug corded models or remove the battery from cordless versions—before changing discs. Inspect all discs for cracks, damage, or excessive wear; damaged discs can shatter at high speeds. Verify the guard is properly installed and functioning correctly, and confirm the handle is securely attached.

Mark the intended cut or grinding area clearly on the workpiece. For cutting applications like tile that may chip differently from each side, mark the outline on both surfaces. Secure the workpiece using clamps or a vise to prevent dangerous movement during operation. Position yourself so sparks and debris fall away from your body, and verify the guard is correctly oriented based on the disc’s rotation direction.

Master Proper Grip and Stance Techniques

Grip the grinder firmly with both hands whenever possible, positioning your body to the side of the disc rather than directly behind it. This stance protects you from kickback events and directs sparks away from your body. Most applications require the grinder to spin away from you, forcing material and sparks downward rather than upward toward your face.

Keep your feet planted shoulder-width apart for stability, maintaining a balanced stance that allows you to quickly pull the tool away if kickback occurs. Allow the disc to reach full operating speed before making contact with the workpiece—typically requiring only a few seconds. Never force the grinder through material; instead, let the disc’s speed do the work. Forcing creates excessive heat, accelerates disc wear, and significantly increases kickback risk.

Execute Precision Cutting Techniques

When cutting metal bars or rods, secure the workpiece so the short end drops away freely after cutting completion rather than becoming trapped and causing disc binding. Allow the spinning disc to drop through the metal under its own weight without applying excessive downward force. Move steadily along the cut line, letting the disc speed do the work while you guide the tool’s trajectory.

For tile or stone cutting, score the surface first by making a shallow cut approximately one-eighth of the way through the material. This initial score prevents disc wandering and helps ensure clean, accurate cuts. Complete the cut from the opposite side, extending past corners slightly to allow clean break-through. When cutting mortar, make two or three parallel cuts staying a few millimeters away from brickwork to avoid damaging adjacent surfaces.

Grind and Remove Material Effectively

For grinding operations, bring the spinning disc into contact with the workpiece at approximately 30 degrees, though specific jobs may require different angles. Move the grinder steadily across the surface, working away from sharp edges and maintaining consistent pressure. Allow the abrasive to do the work rather than pressing hard, which generates excessive heat and accelerates disc wear.

When removing rust or paint, overlap your passes slightly to ensure complete coverage without gouging the underlying surface. Systematic overlapping prevents missed spots while maintaining even material removal. For blade sharpening, secure the blade firmly in a vise, align the grinder disc with the tool’s existing cutting edge at the appropriate bevel angle, and make multiple light passes with steady movement.

Avoid These Common Grinder Mistakes

One of the most dangerous mistakes operators make when learning how to operate a grinder is removing or improperly positioning the safety guard. This critical component protects against disc shattering—never compromise this protection regardless of inconvenience. Another common error involves forcing the tool through material, which generates dangerous kickback while accelerating disc wear.

Neglecting proper workpiece securement creates hazardous conditions as materials shift unexpectedly during cuts. Always clamp workpieces securely before operation—never attempt to cut freehand materials held in your hands. Failing to inspect discs for damage before installation risks catastrophic disc failure at operating speeds.

Maintain Your Grinder for Longevity

Regular maintenance extends tool life and ensures safe operation. Periodically inspect the power cord for damage including cuts or fraying. Check that the guard and handle remain securely attached with all mounting hardware properly tightened. Clean debris from ventilation openings regularly to prevent overheating.

Store the tool in a dry location to prevent corrosion. Keep spare discs organized by type for quick access during projects, and replace worn discs before they become dangerously thin. The spindle bearing assembly may require periodic inspection—unusual noises, excessive vibration, or bearing play indicate developing problems.

Final Thoughts on Safe Grinder Operation

Mastering how to operate a grinder opens possibilities across metalwork, masonry, tile cutting, and countless workshop applications. The tool’s versatility makes it invaluable, but this power demands respect and proper training. By following comprehensive safety protocols, selecting appropriate accessories, and applying correct techniques consistently, you can operate your grinder confidently while minimizing risks.

Remember that safety equipment is never optional, proper preparation prevents accidents, and correct technique produces better results while extending both tool and disc life. Start with less demanding applications to build proficiency before tackling complex cuts. With practice and attention to proper procedures, your angle grinder becomes one of the most valuable tools in your workshop arsenal.