That persistent hum from your basement that never seems to stop is more than just an annoyance—it’s a warning sign. When your grinder pump keeps running continuously instead of cycling on for just 10-30 seconds as designed, you’re facing a serious issue that can lead to motor burnout, sewage backups, and expensive repairs. This abnormal operation means your pump is working overtime without completing its job, creating a dangerous situation where wastewater may eventually back up into your home. The constant operation isn’t just driving up your electricity bills; it’s rapidly accelerating wear on critical components that could fail completely if ignored. Understanding why your grinder pump keeps running is the first step to stopping this costly problem before it escalates into a full-blown emergency that requires professional intervention and potentially thousands in repair costs.

Why Your Grinder Pump Won’t Stop Running

When your grinder pump keeps running, it’s essentially trapped in one of two scenarios: either the float switch falsely signals that water remains in the basin, or the pump is physically unable to move water despite operating. A pump running with an empty basin almost always indicates a float switch problem, while continuous operation with water still present typically points to discharge blockages or mechanical failure. Ignoring this issue has serious consequences—continuous operation generates excessive heat that degrades motor windings and bearings, significantly shortening your pump’s lifespan. What might begin as a simple float switch cleaning can quickly progress to complete pump replacement costing $1,000 or more if left unaddressed. The financial impact extends beyond potential repair costs; a pump running 24/7 can add $30-50 monthly to your electricity bill while simultaneously risking catastrophic sewage backup that causes thousands in property damage.

Float Switch Malfunctions Causing Constant Operation

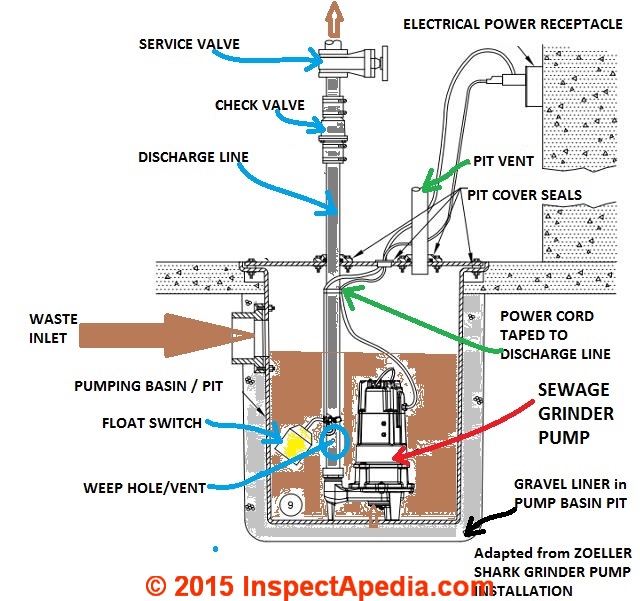

Your float switch acts as the pump’s brain, detecting water levels and triggering activation and shutdown. When this component fails, it becomes the number one cause of continuous running. Debris accumulation on the float mechanism is the most common culprit, with grease, soap scum, and toilet paper fragments restricting movement or causing the float to stick in the “on” position. In documented cases, toilet paper adheres to the float assembly, preventing it from lowering properly even when the basin empties.

To diagnose float switch issues:

1. Disconnect power to the pump

2. Open the basin lid (many systems have split lids for partial access)

3. Visually inspect the float for debris, tangles, or physical obstructions

4. Manually lift the float to its highest position—the pump should activate immediately

5. Lower the float completely—the pump should shut off within seconds

If the pump continues running regardless of float position, the switch has failed and requires replacement. Sometimes simply lifting and dropping the float several times can dislodge internal obstructions and restore temporary function, but persistent problems demand switch replacement to prevent motor damage.

Discharge Pipe Blockages Triggering Continuous Cycling

When your grinder pump keeps running but appears to be moving water, you may have a partial blockage in the discharge piping. These obstructions prevent the pump from emptying the basin efficiently, causing it to operate continuously while moving water at a fraction of normal capacity. Blockages develop through multiple mechanisms: solid waste accumulation from improper disposal, sedimentation narrowing the pipe diameter, grease buildup attracting additional debris, or foreign objects like wipes or cat litter lodging within the system.

The check valve on your discharge line deserves special attention during troubleshooting. A failed swing check valve often masquerades as a complete blockage—when the internal disc breaks free from its hinge or becomes wedged incorrectly, it blocks flow in both directions. In one documented case, a detached disc functioned as a simple blockage, causing continuous running with no discharge. To test for discharge issues, temporarily disconnect the discharge pipe (where accessible) and operate the pump briefly—if water flows freely to a container, the problem lies downstream in the piping or check valve.

Check Valve Failures Mimicking Blockage Symptoms

Check valve failures create symptoms nearly identical to discharge blockages but stem from a specific mechanical component failure. This valve’s critical function is preventing wastewater backflow after pump shutdown, maintaining prime for the next cycle. When it fails, the pump runs continuously trying to achieve or maintain proper flow.

Swing check valves commonly fail when:

– The pivot mechanism corrodes, allowing the disc to rotate freely

– The disc cracks or becomes deformed, compromising its seal

– The retaining pin breaks, releasing the disc to move independently

– Debris prevents proper seating, creating partial blockages

Diagnosing check valve problems requires locating the valve assembly (typically on the discharge pipe above basin level) and examining the internal mechanism. The swing disc should move freely but remain closed when not pushed open by flow. Disconnect the discharge pipe and briefly operate the pump—water should exit forcefully then stop flowing as the valve closes. If water continues trickling or the pump struggles to build pressure, the check valve needs replacement.

Unexpected Water Sources Overloading Your System

If mechanical components check out, continuous running indicates water entering the basin faster than the pump can expel it. Leaking toilets represent the most common hidden water source, with faulty flappers silently adding hundreds of gallons daily to your system. Test for leaks by shutting off each toilet’s water supply overnight—any drop in tank level confirms a leak requiring flapper replacement.

Water softener discharge systems can also overwhelm your pump if regeneration cycles introduce excessive water volume. External sources like high water tables may cause groundwater infiltration through basin seals, while in cold climates, frozen discharge lines restrict flow, forcing the pump to run continuously to achieve minimal discharge. Homeowners have noticed snow melting preferentially over pump locations, indicating warm water discharge or heat from continuous operation.

Motor and Impeller Failures Causing Inefficient Operation

Mechanical degradation of the pump itself can cause continuous running when the impeller fails to move water effectively. Worn impellers lose pumping capacity over time, while debris wrapped around the impeller creates drag that reduces output. In severe cases, foreign objects jam the impeller completely, causing the motor to labor while moving little or no water.

Motor degradation creates similar symptoms when windings overheat from extended operation. Electrical problems including failing start capacitors and corroded connections cause erratic behavior that includes continuous running. To isolate pump mechanical condition, disconnect the discharge pipe and operate the pump—if water flows freely, the pump works and the problem lies downstream; if it struggles or produces no flow, mechanical service is needed.

Quick Diagnostic Steps Homeowners Can Perform

Before calling a professional, try these diagnostic steps:

- Listen to pump operation: Normal pumps cycle briefly with distinct sound changes; continuous operation with no sound variation suggests electrical issues

- Conduct the overnight toilet test: Shut off each toilet’s water supply and check tank levels in the morning

- Inspect the float mechanism: With power disconnected, verify free movement and check for debris

- Observe basin water levels: If the pump runs but water level remains high, discharge issues exist; if level drops but pump continues, float switch has failed

Never attempt electrical repairs without proper training—if you notice sparking, burning smells, or electrical abnormalities, disconnect power immediately and call a professional.

Preventative Maintenance to Avoid Continuous Running

Implement these maintenance practices to prevent future problems:

- Monthly: Check for unusual cycling patterns, strange noises, or corrosion signs

- Quarterly: Inspect float mechanism for debris and verify free movement

- Annually: Schedule professional inspection to test electrical connections and assess system performance

Proper usage prevents most problems—grinder pumps process only human waste and toilet paper. Never flush hygiene products, wipes (even “flushable” ones), cat litter, grease, or food scraps. During high-usage events, spread water-intensive activities across time rather than concentrating them to avoid temporary overloading.

When Professional Help Becomes Essential

Call a qualified technician immediately if:

– You detect electrical problems involving wiring or control boxes

– Sewage backup occurs or seems imminent

– Pump or motor replacement is needed (requires specialized equipment)

– You’ve performed basic diagnostics but the problem persists

Emergency situations involving sewage backup require immediate professional response, with service calls often costing significantly more than preventative maintenance. Establish relationships with qualified providers before emergencies occur to ensure rapid response when needed.

Protecting Your Home Investment from Continuous Pump Failure

A grinder pump keeps running is more than just a noisy nuisance—it’s a warning sign demanding immediate attention. By understanding the common causes—float switch malfunctions, discharge blockages, check valve failures, unexpected water sources, and mechanical degradation—you can diagnose problems accurately and pursue appropriate solutions. Addressing continuous operation promptly prevents motor burnout, avoids costly sewage backups, and restores efficient operation that keeps energy bills under control. Whether the fix involves simple float switch cleaning, toilet leak repair, or professional component replacement, taking action when you notice abnormal operation represents a wise investment in your home’s wastewater infrastructure and your peace of mind. Regular maintenance and proper system usage prevent most continuous running issues from developing in the first place, saving you significant expense and inconvenience down the road.