Angle grinder kickback protection isn’t just a safety feature—it’s your critical last line of defense against serious injury when grinding or cutting metal, stone, or concrete. When a grinding wheel suddenly binds in your workpiece, the tool can whip toward you with enough force to cause broken bones, deep lacerations, or worse in less time than it takes to blink. Modern electronic kickback protection systems detect these dangerous bind events in milliseconds and cut power before reactive torque builds to hazardous levels. Understanding how these systems work, their limitations, and proper operational practices transforms your angle grinder from a potential hazard into a safely controlled tool that protects you on every job.

This guide reveals exactly how kickback protection technology keeps you safe, what features to look for when purchasing a grinder, and the operational techniques that work with—not against—your tool’s safety systems. Whether you’re a professional contractor evaluating new equipment or a DIY enthusiast seeking to understand your tools better, you’ll learn how to maximize protection against the most common cause of angle grinder injuries. Most importantly, you’ll discover why relying solely on human reflexes is dangerous when kickback occurs faster than you can react.

Why Angle Grinder Kickback Causes Severe Injuries in Milliseconds

Kickback happens when your grinding wheel encounters resistance that exceeds its ability to continue rotating, causing the wheel to stop or slow dramatically within milliseconds. As the motor keeps driving forward while the wheel binds, reactive torque whips the tool in the opposite direction of wheel rotation—often directly toward your body. With standard angle grinder wheels spinning at over 10,000 RPM, this sudden release of rotational energy generates substantial force most operators cannot control, even with both hands firmly gripping the tool.

The Physics Behind Unstoppable Kickback Events

Human reaction time proves completely insufficient against kickback’s speed. From the moment a wheel binds to the development of dangerous reactive torque, only 20-50 milliseconds elapse—far faster than the 150-250 milliseconds required for you to perceive danger and react. Electronic protection systems detect rapid deceleration and cut power in 10 milliseconds or less, providing protection your reflexes simply cannot match. This technological advantage explains why professional job sites now mandate kickback control as standard equipment.

Factors That Increase Kickback Severity

Several elements influence how violently your grinder will react when kickback occurs:

– Grinder power output: Higher-powered models generate more reactive force when bind happens

– Wheel condition: Worn or damaged wheels catch unexpectedly in materials

– Workpiece material: Certain metals and composites increase binding risk

– Contact angle: Improper grinding angles dramatically increase kickback likelihood

Understanding these factors helps you recognize high-risk situations before they turn dangerous, though electronic protection remains essential when unexpected bind events occur.

How Electronic Sensors Detect Wheel Bind Before Kickback Occurs

Modern kickback control systems continuously monitor your grinding wheel’s rotational behavior using sophisticated electronic sensors that distinguish between normal cutting resistance and genuine kickback events. These systems analyze deceleration rates in real-time, comparing them against programmed thresholds that separate gradual speed reductions from sudden stops. When a dangerous bind condition is detected, power to the motor cuts within 10 milliseconds—before reactive torque builds to hazardous levels.

Bosch Kickback Control: The Industry Standard Technology

Bosch pioneered kickback control technology for angle grinders in 2010, establishing the foundational approach now used across professional tools. Their system monitors both motor current and wheel speed using algorithms specifically tuned to identify the unique signature of wheel bind versus normal operational variations. Crucially, the activation threshold requires the wheel to be forcibly stopped or nearly stopped, ensuring the system responds only to genuine kickback events rather than normal grinding resistance changes that would disrupt your work.

Multi-Sensor Detection for Reliable Protection

Advanced kickback control implementations integrate multiple sensing elements for dependable detection:

– Motor current sensors detect the sudden electrical demand spike when resistance increases

– Optical or magnetic pickup systems directly measure rotational velocity as secondary verification

– Electronic control modules process inputs simultaneously to confirm genuine kickback events

This multi-layered approach prevents false activations while maintaining sensitivity to actual danger, ensuring your protection system works when you need it most.

4 Critical Electronic Safety Systems in Professional Angle Grinders

Beyond kickback control, professional angle grinders incorporate additional electronic protection that addresses different hazard scenarios you face on the job site. These systems work together to create comprehensive protection against multiple injury mechanisms, with each addressing specific risks that could otherwise cause serious harm.

Restart Protection: Preventing Dangerous Unexpected Tool Activation

Restart protection, introduced by Bosch in 2011, prevents accidental tool startup when power supply is interrupted and restored—a common occurrence when cords get bumped or batteries are reinserted. Without this protection, a grinder that loses power could suddenly restart when you believe it’s safely off, potentially causing severe injury. The system requires deliberate operator action to restore power after any interruption, ensuring you consciously choose to restart the tool.

Intelligent Brake System: Stopping the Wheel Before It Grabs the Work

When you release the switch, the intelligent brake system engages immediately to stop the wheel significantly faster than natural friction would achieve. This rapid stopping capability reduces the window of opportunity for grab-related incidents during coasting periods, allowing you to set the tool down more safely after completing a cut. The brake activates both when you intentionally stop the tool and when kickback control triggers automatic shutdown.

Drop Control Technology: Automatic Shutdown During Accidental Drops

Drop control uses acceleration sensors to detect when your tool is falling, triggering immediate motor shutdown before impact. This feature proves particularly valuable in elevated work scenarios where a falling powered tool could cause serious harm to bystanders below. The system detects fall events within milliseconds and cuts power before the tool strikes the ground or any object in its path.

Momentary Contact Switch: Continuous Pressure Operation for Safety

The momentary contact switch requires constant operator pressure to maintain power, creating a natural safety feedback loop. Unlike toggle switches that can be left running unattended, this design ensures you must maintain physical contact with the switch throughout operation, promoting sustained awareness of the tool’s operating state and reducing the probability of accidental operation.

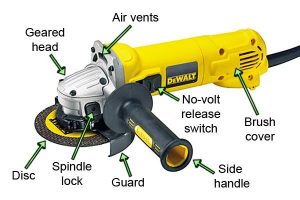

Adjusting Your Angle Grinder Guard for Maximum Kickback Protection

While electronic systems address the tool’s reactive behavior, properly positioned physical guards provide your primary barrier against flying debris, wheel fragments, and sparks during kickback events. The hand guard mounts directly to your grinder’s gear housing, positioning a rigid barrier between the wheel periphery and your hand placement area.

Proper Guard Positioning Techniques

Misadjusted guards leave critical areas exposed or create interference that affects your grinding technique. Follow these positioning guidelines:

– For grinding operations: Position the guard to cover the upper portion of the wheel while exposing the lower grinding surface

– For cutting applications: Rotate the guard to expose the cutting edge while maintaining protection from the top

– Always verify: The guard deflects sparks and debris away from your body and nearby workers

Guard Types for Specific Applications

Different guard configurations serve specific purposes:

– Grinding-specific guards: Optimized for surface work with maximum wheel exposure

– Cutting guards: Feature debris deflection channels and dust collection ports

– Combination guards: Offer versatility for both grinding and cutting tasks

Regularly inspect your guard for damage and ensure all adjustment mechanisms function properly before each use.

Choosing the Right Kickback-Protected Grinder for Your Workshop

When evaluating angle grinders, verify the specific protection features included and confirm they meet your safety requirements. Professional-grade tools from major manufacturers typically include comprehensive protection as standard equipment, while consumer models may offer fewer features or make them optional upgrades.

Critical Protection Features to Prioritize

Focus on these essential safety systems when selecting your next grinder:

– Kickback control: Non-negotiable for serious injury prevention

– Restart protection: Mandatory for safe operation on job sites

– Intelligent brake system: Reduces coasting period hazards

– Vibration control: Essential for operators using grinders extensively

Professional-grade grinders typically command premium prices reflecting the cost of electronic protection systems, but this investment pays dividends through reduced injury risk and potential workers’ compensation claims.

7 Safe Grinding Techniques That Prevent Kickback Events

Even with advanced kickback protection, proper operating technique remains essential for minimizing bind situations. These techniques work with your tool’s safety systems rather than against them:

Body Positioning for Maximum Control

- Maintain firm two-handed grip with thumbs wrapped around the tool body

- Position your body and limbs away from the potential kickback path

- Stand to the side of the wheel rotation path rather than directly behind it

Proper Wheel Engagement Methods

- Avoid applying side pressure that could cause wheel bind

- Maintain appropriate work angles (typically 15-30 degrees)

- Advance the tool into the work at controlled rates without excessive force

- Let the wheel do the work—don’t force it through the material

Pre-Operation Safety Checks

- Inspect the wheel for cracks or damage before installation

- Verify proper guard positioning for your specific task

- Confirm all protection systems function correctly through brief functional tests

Monthly Kickback Protection System Checks Every Operator Must Perform

Protection system reliability depends on proper maintenance and periodic verification. Incorporate these checks into your pre-use inspection routine:

- Kickback control test: Briefly simulate bind conditions (following manufacturer instructions) to verify automatic shutdown

- Restart protection verification: Interrupt power and confirm the tool won’t restart automatically

- Brake system check: Time wheel stopping duration after switch release

- Guard integrity inspection: Look for cracks, damage, or worn adjustment mechanisms

- Vibration control assessment: Check for excessive vibration compared to baseline performance

These simple checks, taking less than two minutes, ensure your protection systems remain ready to respond when needed most.

Final Note: Modern grinder kickback protection systems represent a quantum leap in tool safety, but their effectiveness depends on your understanding of their capabilities and limitations. By selecting equipment with comprehensive protection features, maintaining those systems properly, and applying safe operating techniques, you transform your angle grinder from a potential hazard into a safely controlled tool. Remember that no protection system replaces proper technique—electronic safeguards work best when combined with sound operational practices that minimize kickback risk in the first place. Whether you’re grinding for five minutes or five hours, your safety depends on respecting the tool’s power while leveraging every available protection feature to keep you working safely.