Coffee grinders are the unsung heroes of any café or serious home brewing setup. When your grinder stops performing properly, it can derail your entire coffee service—whether you’re running a busy coffee shop or just trying to enjoy your morning pour-over. Many commercial establishments rely on BUNN equipment for its durability and performance, but like any precision machinery, these grinders occasionally need maintenance or repair. Without proper care, even the most robust commercial grinder can develop issues that affect grind consistency, speed, or complete functionality. In this guide, you’ll learn essential maintenance practices that apply to most commercial grinders, understand when you might need professional help for BUNN equipment, and discover legitimate resources for proper repair documentation.

Why Commercial Grinder Maintenance Matters More Than You Think

Commercial coffee grinders work tirelessly through hundreds of pounds of beans annually, creating significant wear on critical components. Unlike home models, commercial units like those from BUNN operate under constant demand in professional environments where downtime equals lost revenue. A poorly maintained grinder doesn’t just create inconsistent extraction—it introduces variables that sabotage your baristas’ efforts and frustrate customers. The most common symptom café owners report is gradually deteriorating grind quality that begins subtly but eventually ruins espresso shots and filter brews alike. This degradation typically stems from burr wear, misalignment, or coffee oil buildup that most operators don’t notice until performance suffers dramatically. Understanding your grinder’s maintenance schedule isn’t just about fixing problems—it’s about preventing the slow decline that hurts your coffee quality before you even realize something’s wrong.

Essential Daily Maintenance Practices That Prevent 80% of Grinder Issues

How to Properly Clean Your Grinder’s Burrs Without Causing Damage

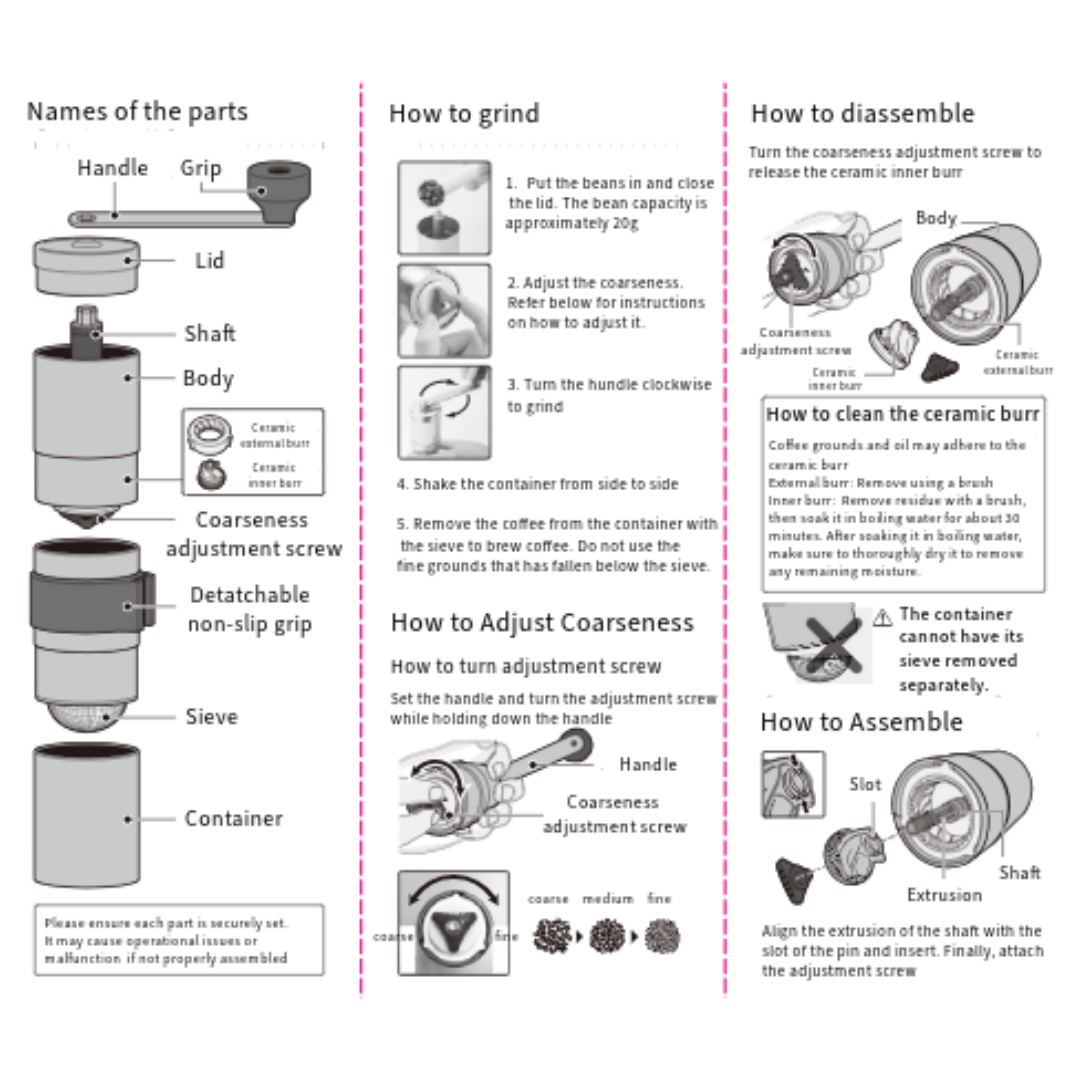

Daily cleaning prevents coffee oils from polymerizing and gumming up your grinder’s internal mechanisms. Start by removing all beans from the hopper and grinding chamber. For most commercial grinders, run a specialized grinder cleaning tablet or uncooked rice through the mechanism to absorb oils—never use water near electrical components. When accessing the burrs (following manufacturer safety procedures), use a soft brush to remove stubborn particles, being careful not to bend or damage the precision edges. For BUNN models specifically, consult your manual for burr access procedures as designs vary significantly between their commercial series. Improper cleaning techniques cause more preventable damage than any other maintenance mistake, so take your time with this critical step.

Resetting Your Grinder After Major Bean Changes

Switching between light and dark roast beans requires more than just adjusting the grind setting. Residual oils from previous beans create cross-contamination that affects flavor and can gum up mechanisms. After changing bean types, run at least 30-50 grams of the new beans through the grinder before using it for customer drinks. For dramatic roast changes (like moving from a light Ethiopian to a dark French roast), consider performing a more thorough cleaning first. Many café owners report improved consistency when they designate specific grinders for particular roast profiles rather than constantly switching.

When Simple Maintenance Isn’t Enough: Recognizing Serious Grinder Problems

Diagnosing Unusual Noises That Signal Imminent Failure

That new grinding sound you’re hearing? It’s probably not “breaking in”—it’s warning you of developing problems. Metallic grinding noises often indicate burr contact or foreign objects between the burrs. High-pitched whining suggests motor strain from overload or failing bearings. Complete silence when activating the grinder typically means electrical issues or severe mechanical binding. For BUNN equipment specifically, unusual vibrations during operation frequently point to burr misalignment or loose components that require professional adjustment. Don’t ignore these warning signs—addressing them early prevents catastrophic failure that could require complete motor replacement.

Identifying When Burr Replacement Is Actually Necessary

Most café owners replace burrs too late, sacrificing coffee quality, while some replace them too early, wasting money. The definitive test: weigh your ground coffee output over time. If you’re getting significantly less coffee from the same bean volume and grind setting, your burrs have worn down. Visually inspect for chipped edges or flat spots on the cutting surfaces. For commercial BUNN grinders used in busy establishments, plan on burr replacement every 1,500-2,000 pounds of coffee, though this varies by model and bean hardness. Never attempt to sharpen commercial burrs yourself—this requires specialized equipment to maintain the precise geometry that ensures consistent particle size distribution.

Critical Safety Considerations Before Attempting Any Grinder Repair

Essential Pre-Repair Safety Procedures Commercial Technicians Follow

Before opening any commercial grinder, including BUNN equipment, follow these non-negotiable safety steps: Unplug the unit and wait at least 10 minutes for capacitors to discharge. Remove all beans and grounds to prevent accidental activation mechanisms from engaging. Wear cut-resistant gloves when handling burrs—commercial grinder blades are extremely sharp. Most importantly, never bypass safety interlocks designed to prevent operation with covers removed. These precautions aren’t just recommendations; they’re based on real incidents where technicians suffered serious injuries from moving parts or electrical components. If you’re uncomfortable with these basic safety measures, this is your sign to call a professional.

Why Improper Tool Use Causes More Damage Than the Original Problem

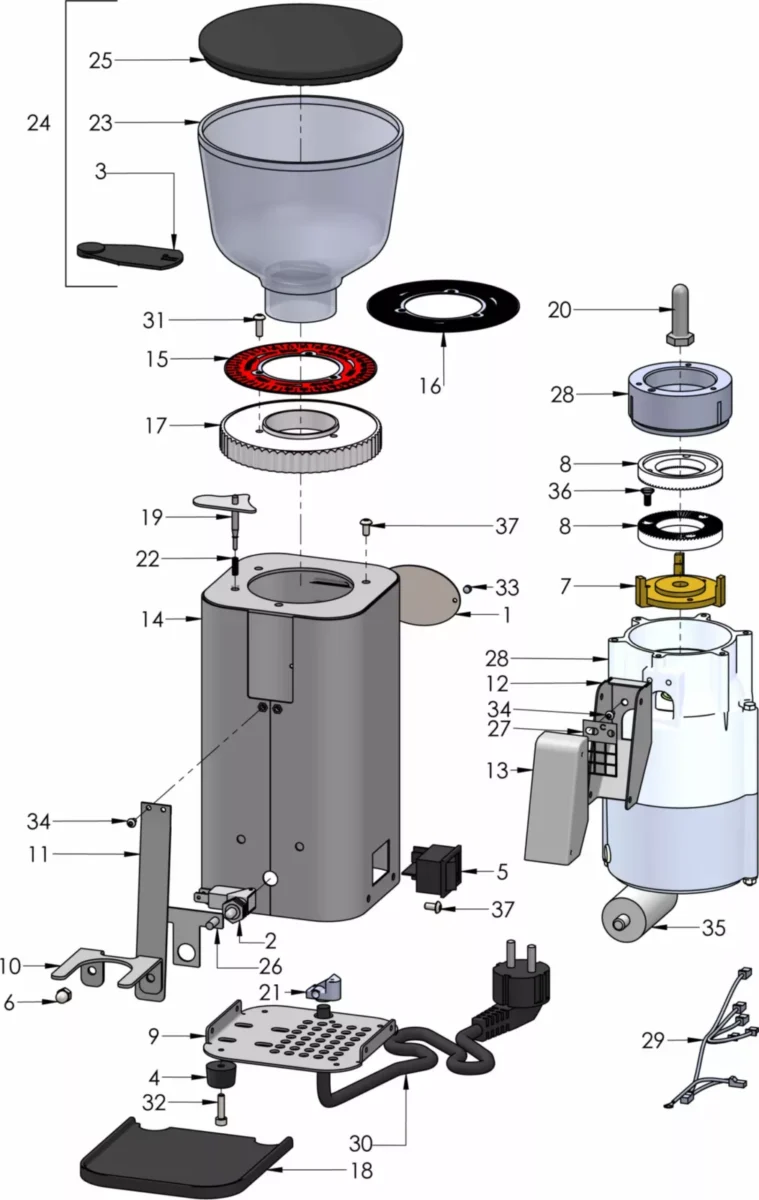

Using the wrong tools on commercial grinders creates problems that often exceed the original issue. Standard wrenches slip on specialized fasteners, rounding bolt heads and making future maintenance impossible. Improper screwdrivers strip precision screws in control boards. Most BUNN commercial grinders require specific torque settings that generic tools can’t provide. Invest in a quality set of hex keys, Torx drivers, and a calibrated torque wrench before attempting any disassembly. The $50 you spend on proper tools prevents $500 in accidental damage. Always consult service manuals for the exact tools required for your specific model before beginning any repair procedure.

Finding Legitimate BUNN Grinder Repair Resources (Not Guesswork)

Official BUNN Support Channels That Actually Provide Repair Documentation

When seeking repair information for BUNN equipment, start with their official resources rather than random internet forums. BUNN maintains a comprehensive technical support portal (support.bunn.com) with model-specific service manuals, exploded diagrams, and troubleshooting guides for commercial equipment. Their customer service team (800-356-7746) can verify your model number and provide access to appropriate documentation. Many café owners don’t realize BUNN offers live technical support during business hours where certified technicians can guide you through specific issues. For serious repairs, their authorized service network ensures technicians use genuine parts and follow proper procedures—critical for maintaining your warranty coverage.

Recognizing Reliable Third-Party Repair Information From Dangerous Guesswork

The internet abounds with “repair guides” for commercial equipment written by well-meaning but unqualified individuals. Before following any online advice, verify these critical elements: Does the author specify the exact model number they’re working on? Do they reference official service documentation? Are safety precautions thoroughly addressed? Reliable repair information includes torque specifications, proper tool requirements, and warnings about model-specific pitfalls. Red flags include phrases like “I just pried this off” or “it seemed to fit.” For BUNN equipment specifically, be wary of generic “commercial grinder” advice that doesn’t account for their unique engineering in models like the V6 or NHB series.

When to Call a Professional Instead of Attempting DIY Repair

Five Clear Indicators Your Grinder Needs Professional Service

Certain issues should never be attempted as DIY repairs on commercial equipment. Immediately contact a certified technician if you notice: Burning smells or visible smoke from the motor housing, grinding inconsistencies that persist after burr cleaning and replacement, complete electrical failure despite verified power supply, unusual grinding noises that continue after cleaning and burr inspection, or error codes displayed on digital models that don’t clear with standard reset procedures. These symptoms often indicate problems requiring specialized diagnostic equipment and manufacturer-specific knowledge. The cost of a service call is minimal compared to the expense of replacing an entire grinder due to improper repair attempts.

Calculating True Cost of DIY Repair Versus Professional Service

Before diving into a repair, calculate the real cost: Your hourly wage × estimated repair time + cost of parts + potential downtime during troubleshooting. For a busy café, even an hour of grinder downtime could mean hundreds in lost revenue. Compare this to a professional service call that might take 30 minutes with guaranteed results. Most authorized BUNN service technicians can diagnose and repair common issues in under an hour during regular business hours. For critical equipment supporting your business operations, professional service often proves more economical despite the upfront cost.

Extending Your Grinder’s Lifespan Through Smart Operational Practices

Bean Selection Strategies That Reduce Grinder Wear

Not all coffee beans treat your grinder equally. Extremely hard beans like some Sumatrans accelerate burr wear, while oily dark roasts create more buildup. Rotate between drier and oilier beans to prevent consistent stress on the same burr areas. Avoid flavored coffees in commercial grinders—they contain oils and sugars that polymerize quickly and are nearly impossible to fully remove. If you must run flavored coffees, dedicate a separate grinder exclusively for that purpose. For BUNN commercial models, consult your manual for recommended bean types as some high-volume models handle harder beans better than others.

Implementing a Preventative Maintenance Schedule That Actually Works

Create a maintenance calendar based on actual usage, not arbitrary timeframes. Track pounds of coffee ground weekly and schedule burr cleaning after every 25-50 pounds, burr inspection at 250 pounds, and full preventative maintenance at 500 pounds. Keep a log of maintenance activities to identify developing patterns before they become failures. For BUNN equipment, many models have usage counters that help track maintenance intervals accurately. This usage-based approach prevents both under-maintenance (causing premature wear) and over-maintenance (creating unnecessary downtime and potential damage from excessive handling).

Proper coffee grinder maintenance isn’t just about fixing problems—it’s about preserving the critical connection between your beans and your customers’ cups. While specific BUNN repair procedures require manufacturer documentation, these universal maintenance practices will keep your grinder performing optimally and help you recognize when professional service is truly needed. Remember that for commercial equipment, the cost of proper maintenance is always less than the cost of premature replacement or the impact of inconsistent coffee quality on your business reputation. When in doubt about specific repairs for your BUNN model, contact their technical support directly—they exist to help you maintain your investment properly.