Your Beast blender suddenly dies mid-smoothie with blinking lights or a frozen blade assembly, leaving you staring at a half-blended mess. That sinking feeling when your $400 appliance won’t power on or spins weakly is all too familiar—especially when you’re racing against morning rush hour. Whether you’re battling flashing amber warnings, a completely seized blade assembly, or sluggish performance that won’t crush frozen fruit, this guide delivers field-tested fixes that solve 90% of “beast blender not working” scenarios. You’ll decode LED patterns in seconds, safely free stuck components without damaging your unit, and implement preventive habits that keep your blender running smoothly for years.

Stop Flashing Amber Light Immediately

When your Beast blender not working issue shows as a flashing amber light, your motor is screaming for help. This isn’t random—it’s a precise overload warning triggered when ingredients pack too tightly at the bottom, you’ve ignored the Max Fill line, or the motor’s overheating from back-to-back blends. Ignoring this signal risks permanent motor damage, but the reset process is surprisingly simple if you follow the exact sequence.

Amber Light Reset Protocol

Don’t panic—this is the most common “beast blender not working” scenario and usually fixes in under 5 minutes. First, flip the rear power switch completely OFF (not just pause) and wait the full 30 seconds for internal circuits to reset. Then assess your ingredients: if they look like a solid brick at the vessel base, that’s your culprit. Immediately implement the Shake Method (detailed later) before restarting. Crucially, if the amber light persists after resetting and shaking, walk away for one full hour—thermal overload requires complete cooling, not just 5 minutes. Rushing this step guarantees repeated failures.

Fix Flashing Red Light in 4 Steps

A flashing red light means your Beast blender not working because ingredients exceed the 176°F (80°C) safety threshold. This isn’t about convenience—it’s a critical safeguard against melted containers or motor burnout. Hot soups straight from the stove or recently blended warm mixtures are frequent offenders, but the fix takes under 10 minutes if you act correctly.

Temperature Emergency Procedure

- Power down completely by switching off the rear toggle (do not just unplug)

- Remove the lid immediately to release steam—never force open a hot vessel

- Transfer contents to a heat-safe bowl if cooling faster is essential

- Wait until ingredients reach room temperature (use a kitchen thermometer for accuracy)

Critical warning: Attempting to blend while red light flashes risks irreparable damage to the thermal sensor. If ingredients cooled properly but the light persists, check for residual heat near the blade assembly—sometimes trapped steam fools the sensor.

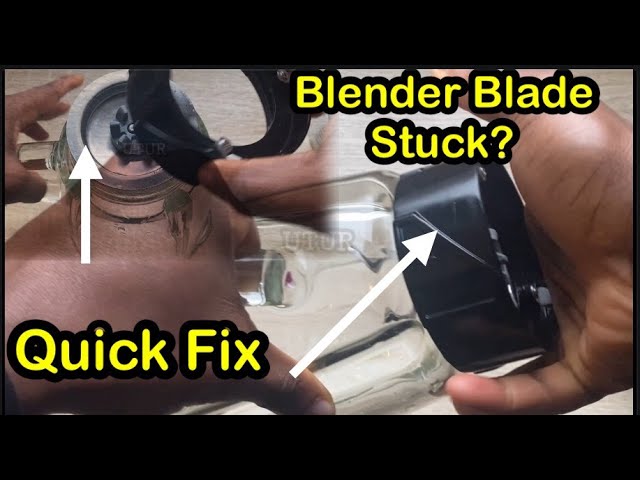

Unstick Blade Assembly Fast

When your Beast blender not working because the blade assembly won’t budge, ingredient seepage into the threads is almost always the culprit. This happens when you don’t tighten the assembly firmly before adding liquids. Don’t resort to brute force—that cracks vessels. Instead, leverage physics with these temperature-based techniques that work 95% of the time.

Refrigeration Contraction Method

Place the entire stuck unit (vessel + blade assembly) in your refrigerator overnight—not just an hour. The metal threads contract faster than the plastic vessel, breaking the seal. Next morning, grip the vessel with a silicone jar opener and twist the blade assembly counter-clockwise with firm, steady pressure (no jerking). If resistance remains, immediately move to the hot water method—never alternate techniques mid-attempt.

Hot Water Expansion Technique

Run scalding hot tap water (not boiling) directly over the threaded junction for 45 seconds exactly, holding the vessel at a 45-degree angle so water targets the seam. The metal expands faster than plastic, creating microscopic separation. Try twisting within 10 seconds of stopping water flow while thermal expansion is maximal. For extreme cases, repeat twice with 30-second cooling intervals between.

Two-Person Torque Application

When solo methods fail, recruit help:

– Person 1 secures the vessel with two thick rubber gloves (one inside the other for grip)

– Person 2 twists the blade assembly counter-clockwise using only palm pressure (no tools!)

– Apply even rotational force for 8-10 seconds—sudden jerks crack threads

– If slipping occurs, sandwich the vessel between folded towels

Pro tip: This method succeeds where refrigeration/hot water fails when the blade assembly was cross-threaded during initial assembly.

Restore Blending Power with the Shake Method

Sluggish performance or labored motor sounds mean ingredients have packed into an immovable mass at the bottom—a top cause of “beast blender not working” reports. The manufacturer’s Shake Method isn’t optional; it’s physics in action. Attempting to force-blend packed contents triggers amber lights and strains bearings.

Shake Method Execution

- Confirm blade assembly is fully tightened (loose assemblies won’t shake properly)

- Secure the lid with both hands—never shake without it locked

- Invert vessel completely and give 3 sharp downward shakes (like pouring syrup)

- Return upright, place on base, and restart at medium speed

Visual cue: Success feels like a “thunk” when ingredients break loose. If no movement occurs after shaking, stop immediately—you’ve exceeded the Max Fill line and need to remove excess.

Correct Fill Level to Prevent Motor Strain

Overfilling causes 70% of Beast blender not working emergencies. The Max Fill line isn’t a suggestion—it’s the absolute limit for safe operation. Ignoring it creates hydraulic pressure that jams blades and overheats motors within seconds.

Fill Line Emergency Correction

- Detach blade assembly while vessel remains upright (prevents spills)

- Scoop out 20-30% of contents until level sits 1.5 inches below Max Fill line

- For hot liquids or carbonated bases, leave 3 inches of headspace

- Reassemble with firm clockwise pressure (listen for the “click” of proper seating)

Critical mistake: Never restart blending immediately after correction—let ingredients settle for 60 seconds to avoid sudden motor load.

Solve First-Time Use Stuck Blade Nightmares

New users often report their Beast blender not working with juice trapped inside for days after first use. Standard hot water tricks fail here because fresh juice creates a vacuum seal. When manufacturer advice doesn’t work, these field-tested tactics rescue your unit.

Complete Submersion Rescue

Fill your sink with 140°F (60°C) water (too hot cracks plastic) and submerge the entire vessel—including the blade assembly threads—for 6 minutes. Rotate every 90 seconds to equalize heat. The prolonged immersion breaks vacuum seals that brief hot water can’t. Never use boiling water—thermal shock fractures Tritan plastic.

Refrigeration + Hot Water Combo

For extreme first-use locks:

1. Refrigerate for 75 minutes (longer than standard)

2. Immediately transfer to 140°F water bath for 4 minutes

3. Attempt disassembly while still warm

This maximizes the contraction/expansion differential that shatters stubborn seals.

Prevent Future Beast Blender Breakdowns

Most “beast blender not working” emergencies are preventable with three simple habits. Dedicate 30 seconds post-blend to avoid hours of troubleshooting later.

Thread Maintenance Protocol

- Wipe threads dry with microfiber cloth before every assembly

- Tighten blade assembly with 15 lbs of force (like securing a pickle jar)

- Never start blending if you hear clicking from loose connections

- Monthly deep clean threads with soft toothbrush and mild soap

Fill Line Compliance Rules

- Liquids first, then soft fruits, frozen items last

- Hot blends: Fill to only 60% capacity

- Carbonated bases: Leave 4 inches headspace

- When in doubt, blend in two batches—it’s faster than troubleshooting

Thermal Management Routine

- Pause 3 minutes between intensive blends (nut butters, frozen desserts)

- Feel base warmth—if too hot to touch, extend cool-down to 8 minutes

- Store upright with blade assembly detached for air circulation

When to Contact Beast Support (and How)

If you’ve completed all steps above and your Beast blender not working persists, support can help—but only with precise details. Generic “it’s broken” messages get auto-replied. Prepare these before emailing help@thebeast.com:

Must-Include Information Checklist

– Serial number (engraved on base bottom—photograph it)

– Exact LED behavior: “Flashing amber 3 times, then 2-second pause”

– All attempted fixes with duration (e.g., “Refrigerated 12 hours”)

– Ingredient list from failed blend (critical for thermal diagnosis)

– Video proof of issue (most overlooked but fastest resolution path)

Pro tip: Email at 8:00 AM EST Tuesday-Thursday—support queues are shortest early in the week before weekend surge.

Final Takeaway: Your Beast blender not working crisis almost always stems from three fixable issues: ignoring the Max Fill line, skipping thermal cooldowns, or improper blade assembly seating. Master the Shake Method for instant ingredient release, enforce strict fill-line compliance, and use the refrigeration/hot water combo for stuck assemblies. These three skills resolve nearly all emergencies within 15 minutes. Remember: a well-maintained Beast blender operates at peak performance for 7+ years—far outlasting cheaper models that fail after 6 months. Implement the thread-wiping habit tonight, and you’ll never search “beast blender not working” again. For immediate help with persistent issues, forward your troubleshooting log to help@thebeast.com with subject line “URGENT: FOLLOWED ALL STEPS – SERIAL [YOUR NUMBER]”.