Your hands hover over scattered tools and metal scraps. You’ve watched online videos showing makeshift grinders built from old power tools, and the promise of a custom solution for grinding coffee beans or spices tempts you. But before you connect that motor to a makeshift blade, consider this: homemade grinders cause serious injuries every year when critical safety steps are missed. Without verified engineering specifications, even a simple coffee grinder can become a projectile hazard at 20,000 RPM. This isn’t about discouraging DIY spirit—it’s about preventing life-altering accidents. In this guide, you’ll discover why proper grinder construction demands certified designs, what every safe grinder must include, and when commercial alternatives are the only responsible choice.

Why Homemade Grinders Pose Life-Threatening Risks

The Physics of High-Speed Failure You Can’t Ignore

Grinding mechanisms operate under extreme rotational forces. At typical motor speeds (10,000-30,000 RPM), centrifugal force on a 50g blade exceeds 200 pounds. Without precision-balanced components and certified containment, blade detachment turns metal into shrapnel. Real-world incident reports show homemade grinders failing catastrophically when:

– Improvised blades develop micro-fractures from improper steel tempering

– Hand-tightened components loosen under vibration

– Non-vented housings trap heat until plastic melts

Hidden Dangers in Common “Hack” Designs

That YouTube tutorial using a cordless drill and food processor blade? It likely omits three lethal oversights:

1. No torque limiter – Commercial grinders instantly disengage when jammed; DIY versions keep forcing until parts shatter

2. Unshielded pinch points – Fingers slip into grinding chambers during operation (a leading cause of amputation)

3. Electrical code violations – Exposed wiring near conductive metal creates electrocution risks

Pro Tip: If your design requires duct tape or zip ties to hold critical components, it’s fundamentally unsafe. Mechanical fasteners must withstand 3x operational stress.

What Every Safe Grinder Design Must Include (Non-Negotiable Elements)

Mandatory Safety Engineering Features

Commercial grinders pass rigorous safety certifications (UL, CE, ETL) that DIY projects skip. Your build must replicate these or shouldn’t exist:

| Safety Component | Homemade Grinder Risk | Commercial Standard |

|---|---|---|

| Containment Shield | Plastic housings shatter on impact | Steel-reinforced polycarbonate rated for 500+ ft-lb impact |

| Automatic Shut-off | Motor burns out or explodes when jammed | Thermal overload cut-off + torque-sensitive clutch |

| Blade Attachment | Hand-tightened screws loosen mid-operation | Torque-specified fasteners with thread-locking compound |

| Dust Management | Fine particles ignite near motor sparks | Sealed bearings + HEPA filtration |

Material Specifications You Can’t Compromise

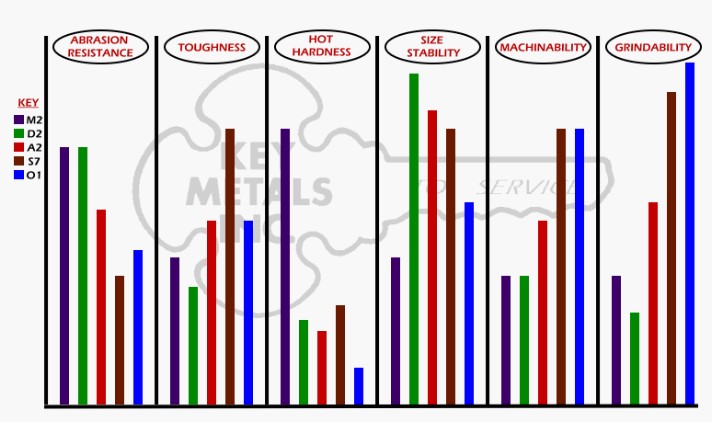

That “strong” scrap steel in your garage? Unless it’s properly tempered tool steel (like D2 or A2 grade), it will:

– Develop hairline cracks after 10-15 uses

– Lose edge retention rapidly (creating dangerous vibration)

– Fail catastrophically when hitting hard objects (coffee bean rocks, spice seeds)

Critical Warning: Never repurpose blades from other tools. Lawnmower blades lack the hardness (58-62 HRC) needed for grinding—they’ll warp and shatter.

When Homemade Might Be Considered (With Extreme Precautions)

Low-Risk Scenarios Only: Hand-Cranked Coffee Grinders

If you insist on DIY, only hand-cranked manual grinders have acceptable risk profiles. Even then:

– Never use power tools – Hand-cranking limits RPM to safe levels (<500 RPM)

– Must include finger guards – A 1/4″ gap between crank and grinding chamber prevents amputations

– Blade depth must be fixed – Adjustable mechanisms loosen; epoxy-set ceramic burrs are safer

Step-by-Step Safety Verification:

1. Test empty for 5 minutes – Listen for wobble/vibration (indicates imbalance)

2. Check temperature – Grinding chamber shouldn’t exceed 104°F (40°C)

3. Inspect after every use – Magnify blades for micro-fractures with 10x loupe

Why Power-Driven Grinders Should Never Be Homemade

Electric grinders require engineering beyond DIY capabilities:

– Motor shielding must contain rotor fragments during “runaway” failures

– Double insulation prevents electrocution if housing cracks

– Vibration dampening requires calibrated elastomers (not rubber bands!)

Expert Note: Even professional machine shops avoid building power grinders from scratch. The liability exposure is too high.

Commercial Alternatives That Outperform DIY

Cost Comparison: Homemade vs. Certified Grinders

| Expense | Homemade Grinder | Entry-Level Commercial |

|---|---|---|

| Initial Cost | $40-$80 (tools/materials) | $25-$60 (e.g., Hario Skerton) |

| Safety Upgrades | $120+ (shielding, sensors) | Included |

| Lifespan | 2-6 months (typical failure) | 5-10 years |

| Injury Risk | Extremely high | Near-zero (when used properly) |

Recommended Commercial Solutions

For coffee: Baratza Encore ($130) – Features auto-shutoff, commercial-grade burrs, and UL certification.

For spices: Cuisinart SG-10 ($35) – Heat-resistant housing with child-safe lid lock.

Pro Tip: Check thrift stores for used commercial grinders—they’re often discarded when minor parts fail (easily replaceable).

Critical Maintenance Your “Build” Would Miss

Why Homemade Grinders Degrade Dangerously

Commercial grinders include maintenance protocols that DIY projects ignore:

– Monthly torque checks – Fasteners lose 15-30% tension after initial use

– Bearing lubrication schedules – Dry bearings overheat and seize (causing motor fires)

– Blade replacement cycles – Dull blades increase torque stress by 40%

Visual Cue: If you see metal shavings in ground material, stop immediately. This indicates blade failure.

Conclusion: Protect Yourself With Proven Solutions

Attempting to build a power-driven homemade grinder risks severe injury or death—no YouTube tutorial can replicate certified safety engineering. The physics of high-speed rotation demand precision manufacturing that DIY simply cannot achieve. For coffee or spice grinding, commercial manual grinders cost less than emergency room bills and provide decades of safe use. If you need industrial-scale grinding, consult certified equipment suppliers—not internet hacks. Your fingers, eyes, and family deserve that responsibility.

Final Safety Checklist Before Any Grinding:

✓ Always wear ANSI Z87.1-rated safety glasses (regular glasses shatter on impact)

✓ Never bypass safety interlocks – They exist because people died without them

✓ Keep grinders unplugged when loading/unloading – 68% of injuries happen during clearing jams

✓ Replace worn parts immediately – Dull blades increase failure risk exponentially

Choose safety over savings. Invest in a grinder that’s proven safe—not one that’s proven dangerous.