When your Metabo angle grinder stops working properly, the right repair path matters more than you might think. Unlike simpler tools, angle grinders contain high-speed rotating components and electrical systems that demand professional handling. Many DIY repair attempts end with further damage to the tool or, worse, injury to the user. The good news is Metabo provides structured support channels for legitimate repair services – you just need to know where to look. This guide shows you exactly how to navigate Metabo’s official repair ecosystem to get your grinder back in working condition safely and efficiently, without risking dangerous DIY fixes or counterfeit parts.

Locating Authorized Metabo Service Centers

How to Find Your Nearest Certified Repair Facility

Metabo maintains a global network of authorized service centers that technicians trust for genuine parts and proper repair procedures. The official website navigation shows “Service addresses” as a primary menu option, indicating this is a critical resource for users needing professional assistance. Unlike third-party repair shops that may lack specialized training, Metabo-certified technicians receive specific instruction on their tool designs and safety protocols.

To locate your nearest authorized service center:

1. Visit the official Metabo website (metabo.com)

2. Navigate to the “Service addresses” section

3. Enter your location or select your region

4. Review the certified facilities with their contact information

Critical safety note: Never attempt internal repairs on angle grinders without proper training. The high-RPM components can cause catastrophic failure if improperly reassembled, potentially sending metal fragments at lethal speeds.

Why Authorized Service Centers Outperform General Repair Shops

Authorized Metabo service facilities offer three critical advantages over general tool repair shops. First, they have access to genuine Metabo replacement parts that match original specifications – a crucial factor since aftermarket components often fail under the extreme stresses of angle grinder operation. Second, technicians receive factory training specific to Metabo’s unique engineering, including proper torque specifications for critical components that affect safety. Third, these centers maintain calibrated diagnostic equipment designed specifically for Metabo tools, ensuring accurate problem identification rather than guesswork.

Pro tip: When contacting a service center, ask specifically if they’re “Metabo-authorized” rather than just claiming to repair Metabo tools. Many shops will attempt repairs without proper training or parts.

Navigating the Metabo Warranty Service Process

Determining If Your Grinder Qualifies for Warranty Coverage

The Metabo website’s “Warranty service” section indicates a structured process for warranty claims, but understanding eligibility requirements prevents frustrating dead ends. Most Metabo professional-grade angle grinders carry a standard 1-3 year warranty depending on model and region, but this coverage has specific conditions that users often overlook.

Your grinder likely qualifies for warranty service if:

– It shows no signs of misuse (like attempting to cut materials it’s not designed for)

– It hasn’t been modified or repaired by unauthorized personnel

– You can provide proof of purchase within the warranty period

– The failure stems from material or manufacturing defects

Common warranty voiding mistakes: Using incorrect accessories, operating in wet conditions against specifications, or attempting DIY repairs before seeking authorized service.

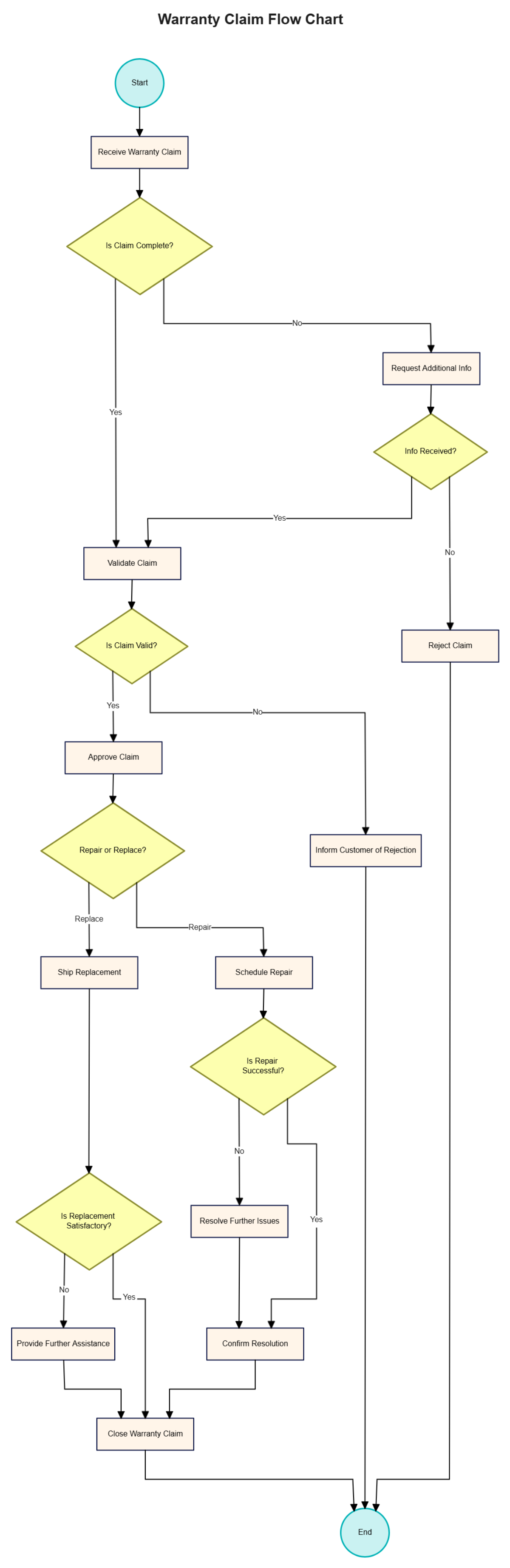

Step-by-Step Warranty Claim Submission

Submitting a successful warranty claim requires following Metabo’s specific process rather than assuming standard manufacturer procedures. The website’s structure suggests a defined workflow that begins with proper documentation:

- Gather your original purchase receipt showing date of purchase

- Note the complete model and serial number from your grinder’s nameplate

- Document the specific failure mode with photos or video if possible

- Contact an authorized service center (not Metabo directly in most regions)

- The service center will evaluate and submit the warranty claim on your behalf

Critical insight: Metabo typically processes warranty claims through service centers rather than direct consumer submissions. Attempting to contact Metabo directly often results in being redirected to an authorized facility anyway.

Obtaining Genuine Metabo Replacement Parts

Why Genuine Parts Matter for Angle Grinder Safety

The “Spare parts” section prominently featured in Metabo’s navigation underscores the importance of using manufacturer-approved components. Angle grinders operate at extreme rotational speeds (often exceeding 10,000 RPM), creating forces that demand precisely engineered parts. Counterfeit or generic replacement components frequently fail catastrophically under these conditions.

Danger zone: Using non-genuine guard assemblies, flange components, or spindle threads creates serious safety hazards. A single point of failure in these critical components can cause the grinding disc to detach at full speed.

How to Verify Authentic Metabo Parts

With counterfeit tool parts increasingly common online, verification has become essential. Metabo’s website structure indicates they provide mechanisms for authenticity verification:

- Look for official Metabo part numbers stamped on components

- Check for the Metabo holographic security label on packaging

- Purchase exclusively through authorized distributors listed on metabo.com

- Use the “Certificate verification” system referenced in the website navigation

Warning: Parts sold at prices significantly below Metabo’s suggested retail often indicate counterfeits. When safety is at stake, this isn’t an area to seek bargains.

Accessing Metabo Operating Instructions and Technical Documentation

Finding Model-Specific Maintenance Guidelines

The “Operating instructions” section in Metabo’s website navigation provides access to critical documentation most users overlook until problems occur. These manuals contain model-specific maintenance requirements that prevent many common failures. Unlike generic angle grinder advice found online, Metabo’s official documentation addresses the precise engineering of your specific model.

Essential maintenance tasks covered in operating instructions:

– Proper brush replacement intervals and procedures

– Lubrication points and recommended lubricants

– Cooling system maintenance requirements

– Vibration analysis thresholds indicating internal problems

– Safe storage protocols to prevent moisture damage

Understanding Metabo’s Technical Documentation Structure

Metabo organizes technical information hierarchically, with different documentation serving specific purposes. Users often confuse operating instructions with service manuals, leading to frustration when attempting repairs beyond their skill level.

Documentation types and their purposes:

– Operating instructions: Basic usage, safety precautions, and user-level maintenance

– Service manuals: Authorized technician procedures for internal repairs

– Parts catalogs: Exploded diagrams with genuine part numbers

– Technical bulletins: Updates addressing specific field issues

Key insight: Metabo typically restricts full service manuals to authorized technicians, explaining why consumers struggle to find detailed repair information online.

Creating Your Metabo Account for Enhanced Service Access

Why Registering Within 4 Weeks Matters

The website navigation indicates a specific account requirement: “Account creation (with 4-week purchase registration requirement).” This suggests Metabo encourages users to register new tools promptly to activate certain service benefits. While exact benefits vary by region, timely registration typically enables:

- Extended warranty options

- Priority service scheduling

- Direct access to technical support

- Recall notifications for safety-related issues

Critical deadline: The 4-week window implies that delayed registration may limit your service options. Set a calendar reminder when purchasing new equipment.

Certificate Verification System for High-Value Repairs

For professional-grade Metabo angle grinders used in industrial settings, the certificate verification system referenced in the website navigation provides additional security for major repairs. This feature helps verify that:

- Repairs meet Metabo’s safety standards

- Only authorized technicians performed the work

- Genuine parts were used in the repair process

- The tool has passed post-repair safety testing

Professional tip: In regulated industries, this verification may be required to maintain compliance with workplace safety standards after repairs.

When to Consider Replacement Over Repair

Evaluating Cost-Benefit of Metabo Grinder Repairs

Even with proper service channels, some repairs aren’t economically sensible. Metabo’s structured service ecosystem helps you make informed decisions by providing transparent cost estimates before committing to repairs.

Repair vs. replacement decision factors:

– Repair cost exceeding 60% of new tool price

– Availability of newer models with safety improvements

– Age of the tool (older than 5 years often lacks parts support)

– Frequency of previous repairs indicating systemic issues

Strategic insight: Sometimes upgrading to a newer Metabo model proves more cost-effective when factoring in downtime and recurring repair costs of aging equipment.

Proper Disposal of Unrepairable Metabo Grinders

When replacement becomes necessary, responsible disposal matters. Metabo’s service infrastructure typically includes guidance for proper recycling of electronic components and metals. Never simply discard power tools in regular trash due to:

- Environmental hazards from electronic components

- Potential safety risks from damaged batteries in cordless models

- Legal requirements for electronic waste disposal in many regions

Eco-friendly option: Many authorized service centers accept old tools for proper recycling, sometimes offering trade-in values toward new purchases.

Final Note: While the temptation to attempt DIY repairs on your Metabo angle grinder might seem cost-effective initially, the potential consequences of improper repairs make professional service the only safe choice. By leveraging Metabo’s official service channels—from authorized repair centers to genuine parts and proper documentation—you protect both your investment and, more importantly, your safety. When working with high-speed rotating tools, there’s simply no room for compromise on proper repair procedures. Bookmark the Metabo service sections on their website now so you’re prepared when issues arise, and always prioritize certified expertise over improvised fixes with these powerful tools.