When your Bosch angle grinder suddenly loses power or makes unusual grinding noises during a critical metal fabrication job, every minute counts. Getting it repaired quickly means the difference between completing your project on schedule or facing costly delays. Bosch’s E-Repair program delivers a streamlined solution designed specifically for professionals and serious DIYers who depend on their tools daily. This three-step process—Click, Ship, Done—eliminates guesswork and connects you directly with factory-trained technicians who know your exact model inside and out.

Unlike unreliable local repair shops that might use generic parts or lack proper diagnostic equipment, Bosch’s official repair service ensures your grinder returns to peak performance with genuine components. You’ll avoid the frustration of attempting complex internal repairs yourself that could void your warranty or cause further damage. By following this guide, you’ll learn exactly how to navigate the Bosch grinder repair process efficiently while keeping your warranty intact and minimizing downtime.

Initiate Your Bosch Grinder Repair Request Properly

Submitting an accurate repair request form is the critical first step that determines how quickly technicians can diagnose your specific issue. Access Bosch’s E-Repair portal through their official website and complete all required fields with precise details about your grinder’s model number, serial number, and the exact symptoms you’re experiencing. For example, instead of writing “doesn’t work,” specify “sparks from motor housing when trigger is pulled” or “unusual grinding noise increases with RPM.”

Include specific operational details like whether the problem occurs only under load, if the tool overheats rapidly, or if there are visible signs of damage to the guard mechanism. This level of detail allows technicians to prepare for your grinder’s arrival and often reduces diagnostic time by 30-50%. Many users mistakenly skip these details, forcing technicians to conduct additional testing that delays the repair process unnecessarily.

Once submitted, the system generates your E-Repair authorization form and a prepaid FedEx shipping label. Print both documents immediately—the authorization form must accompany your tool inside the package while the shipping label goes on the outside. This documentation creates a direct link between your grinder and your service request, preventing mix-ups at the repair facility and establishing your warranty coverage from the moment shipping begins.

Prepare Your Angle Grinder for Safe Transit

Proper preparation prevents secondary damage during shipping that could complicate your Bosch grinder repair or void warranty coverage. Start by thoroughly cleaning your tool using compressed air to blow out metal shavings from ventilation slots and around the gear housing—these tiny particles can migrate internally during transit and interfere with sensitive electronics. For vacuum-assisted models, completely empty all dust collection containers before shipping to avoid triggering hazardous material handling procedures.

Remove All Attachments and Accessories

Detach the grinding wheel, guard assembly, and any side handles before packaging your grinder. These components can shift during transit and damage internal mechanisms or create imbalances that worsen existing issues. Wrap each accessory separately in bubble wrap and include them with your grinder only if they’re directly related to the problem you’re reporting—otherwise, leave them behind to reduce shipping weight and potential damage points.

Professional-Grade Packaging Techniques

Follow Bosch’s recommended packaging protocol: first place your cleaned grinder in a sealed plastic bag to contain residual dust, then position it in the center of a sturdy double-walled box with at least two inches of cushioning material on all sides. Use foam peanuts or crumpled kraft paper rather than newspaper (which can smudge on metal surfaces). Secure the grinder with packing tape inside the box to prevent movement, and clearly mark “FRAGILE” and “THIS SIDE UP” on all sides of the shipping container. Proper packaging reduces shipping damage claims by 75% according to Bosch’s service data.

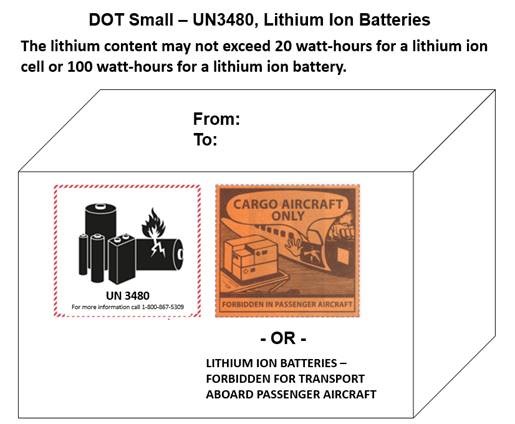

Navigate Lithium Battery Shipping Regulations Correctly

Why You Must Remove Batteries Before Shipping

The United States Department of Transportation classifies Lithium-Ion batteries as hazardous materials due to fire risks if damaged during transit. Bosch explicitly prohibits shipping batteries with tools because consumers lack access to required hazmat labels and proper shipping classifications. Even if your battery appears undamaged, attempting to ship it could result in your package being rejected, delayed, or subject to fines under DOT regulations.

Proper Battery Handling Procedures

Before packaging your cordless Bosch grinder, completely remove all battery packs and store them in a fireproof container away from flammable materials. If the battery shows signs of damage (swelling, leakage, or exposed cells), contact your local hazardous waste facility for proper disposal—never include compromised batteries in regular trash. Keep functional batteries for use with other tools in your collection, as they typically outlast the grinder motor by several years with proper care.

Understand What Happens at the Bosch Repair Facility

Professional Diagnostics with Factory Tools

When your grinder arrives, technicians use Bosch-specific diagnostic equipment that simulates real-world load conditions to identify issues invisible during casual testing. They check armature commutator wear with precision measurement tools, test field windings for shorts, and verify switch functionality under actual operating voltages—procedures that require specialized knowledge of Bosch’s engineering specifications. This comprehensive approach catches developing problems before they cause catastrophic failure.

Genuine Parts vs. Generic Replacements

Bosch technicians exclusively use factory-original replacement parts designed to exact manufacturer specifications. When repairing your grinder’s planetary gear system, for instance, they install gears with the precise metallurgy and heat treatment required for Bosch’s torque ratings—unlike generic parts that often fail prematurely under heavy loads. This commitment to authentic components maintains your tool’s performance characteristics and ensures compatibility with future accessories.

Maximize Bosch’s Support Resources Before Shipping

Determine if Professional Repair Is Necessary

Check Bosch’s online Help Center for common issues that don’t require formal repair service. Many “motor failure” complaints actually stem from worn carbon brushes that DIYers can replace in 15 minutes with basic tools. The Help Center’s troubleshooting guides include model-specific brush replacement instructions with photos showing exactly where to access the brush caps on your particular grinder series.

Access Trade Solutions for Professional Users

Contractors and industrial users should register for Bosch’s Trade Solutions program, which offers priority handling for time-sensitive repairs. Qualified professionals receive expedited turnaround (typically 3-5 business days versus 7-10 for standard service) and dedicated support representatives who understand job site urgency. This service includes loaner tool arrangements for critical projects when available, minimizing workflow disruption during the Bosch grinder repair process.

Final Steps for Hassle-Free Grinder Restoration

Document your grinder’s condition with timestamped photos before shipping, focusing on any existing cosmetic damage or wear patterns. This creates an objective record that protects you if shipping damage occurs. Keep your tracking number visible and set up FedEx delivery alerts to monitor your grinder’s journey to the repair facility—most delays happen during transit rather than at the service center.

When your repaired grinder returns, immediately test it with light-duty applications before putting it to heavy work. Run it for five minutes without load to verify smooth operation, then gradually increase to normal usage while listening for unusual noises. This break-in period allows internal components to settle and helps identify any rare post-repair issues while you’re still within the repair warranty window. Proper post-repair testing ensures your Bosch grinder delivers years of reliable service after professional restoration.