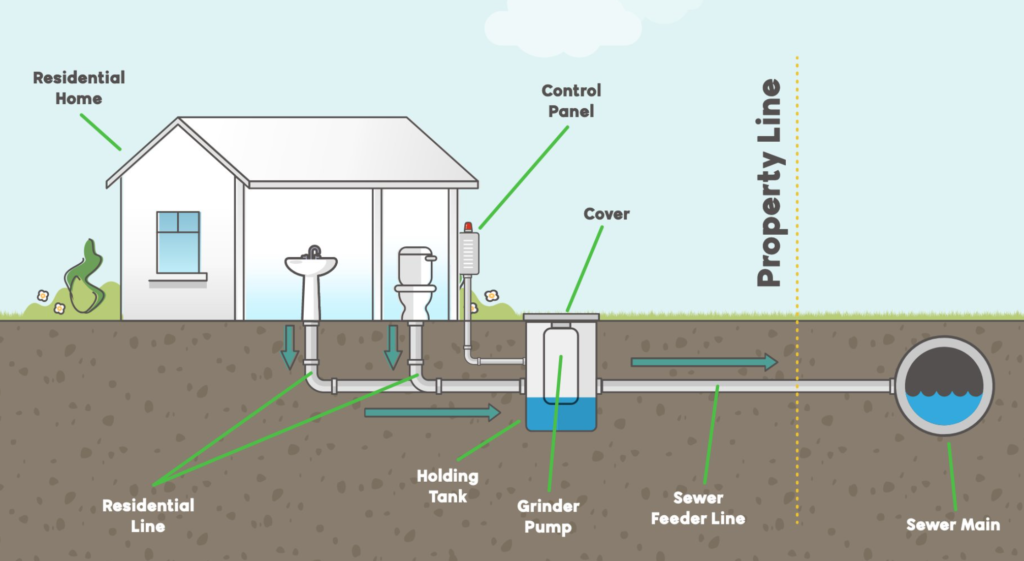

Your grinder pump quietly handles wastewater from your home every day, grinding sewage into slurry and pumping it toward the municipal sewer line. Most homeowners never think about this critical system—until it fails. When your grinder pump stops working, you face inconvenient alarms, costly service calls, and potential sewage backups that can damage your property. Understanding proper grinder pump maintenance isn’t just technical knowledge—it’s essential protection for your home investment. This guide delivers specific, actionable steps you can take today to prevent expensive failures and keep your system running reliably for years.

Why Your Grinder Pump Fails Without Regular Maintenance

Grinder pumps contain mechanical components that shred solid waste into fine slurry before pumping it toward sewer lines. Unlike gravity-based systems, these pumps require active care because they combine electrical systems with moving mechanical parts that wear down without proper attention. The holding tank provides limited storage capacity—typically several hundred gallons—meaning continued water usage during pump failures will eventually cause sewage backups. Most homeowner insurance policies don’t cover damage from neglected maintenance, making proactive care financially essential rather than optional.

How Improper Waste Disposal Damages Your Pump

Cooking grease represents the #1 destroyer of residential grinder pumps. When fats, oils, and grease enter your system, they congeal as they cool, accumulating inside the pump mechanism, discharge pipes, and holding tank. This buildup creates blockages that force your pump to work harder, eventually causing mechanical failure. Never pour cooking fat down sinks, toilets, or drains—the damage extends beyond your pump to your home’s internal plumbing.

What Happens When You Ignore Landscape Protection

Planting flowers or shrubs directly over your grinder pump station creates multiple risks. Buried electrical power and alarm wires run between the control panel and tank, making accidental damage during gardening a serious concern. Before any excavation near your pump station, dial 811 to have utilities marked—this free service prevents catastrophic damage to buried cables. Never drive vehicles or operate lawnmowers over the station lid, as vibration can crack the tank or damage critical components.

Emergency Response Protocol for Alarm Activation

When your grinder pump station alarm sounds, immediate action prevents sewage backups and property damage. Follow this exact sequence to protect your home:

- Immediately stop all water usage throughout your household—no flushing toilets, running showers, or doing laundry

- Silence the alarm by pressing the button on the bottom of the control panel box (the light will stay on)

- Wait 20 minutes before taking further action—many high-water conditions resolve spontaneously

- If the light remains on after 20 minutes, contact your utility provider or trusted plumber

Never attempt to open the pump station lid yourself—this exposes you to sewage, electrical hazards, and potential falls into the tank. Professional technicians have the proper safety equipment and training to handle these emergencies safely.

Rain-Related Alarm Troubleshooting Steps

Recurring alarms during rainy weather indicate surface water infiltration—a common but fixable problem. Follow these steps to identify and resolve the issue:

Check Downspout and Sump Pump Placement

If your downspouts or sump pumps discharge water toward your grinder pump station, redirect them at least 10 feet away. Water flowing directly onto the station lid seeps into the tank, triggering false alarms and reducing pump lifespan through unnecessary cycling.

Inspect for Physical Damage

Look for these warning signs around your pump station during wet weather:

– Cracks in the lid or vent pipe

– Missing bolts on the lid assembly

– Submerged lid during rain events

– Visible water pooling around the station

If you notice any damage or consistent submersion, contact a professional for assessment. Solutions may include gasket replacement, crack repair, or installing basin extensions to raise the opening above water levels.

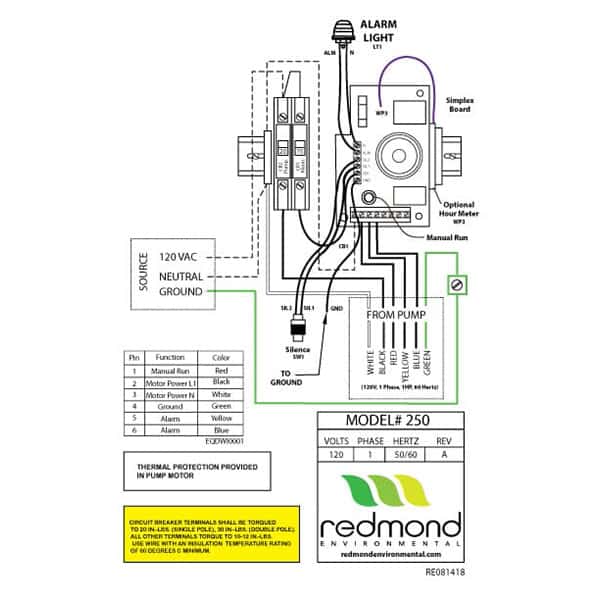

Breaker Reset Procedure for Non-Working Pumps

When your grinder pump fails to activate, 80% of the time it’s simply a tripped breaker—not a mechanical failure. Save hundreds in unnecessary service calls by following this systematic electrical check:

- Locate your home’s main electrical panel and identify the dedicated grinder pump breaker

- Check if it’s in the tripped position (usually mid-way between on and off)

- Flip it fully to “off” then back to “on” to ensure proper reset

- Inspect the secondary breaker at the grinder station control panel

- Verify the control panel toggle switch is set to “Auto” mode

This simple process resolves most “pump failure” emergencies. Only call for professional service if both breakers stay in the “on” position and the pump still doesn’t activate after verifying the control switch position.

Continuous Pump Operation Emergency Fix

A grinder pump running non-stop indicates a serious problem requiring immediate attention. Unlike normal operation (10-20 activations daily, each lasting about one minute), continuous operation accelerates wear and risks complete motor failure. Follow these steps:

First, Check for Hidden Water Sources

- Test all toilets for silent leaks (add food coloring to the tank—if it appears in the bowl without flushing, you have a leak)

- Inspect under sinks for dripping faucets

- Verify outdoor spigots are fully shut off

Then, Verify Control Settings

Ensure the control panel toggle switch isn’t accidentally set to “Hand” or “Manual” mode, which keeps the pump running continuously regardless of tank level.

Emergency Shutdown Procedure

If the pump continues running after checking these items:

1. Immediately limit all household water usage

2. Turn off power at your home’s breaker panel

3. Contact your utility provider or plumbing contractor

Leaving the pump running risks complete motor burnout, which costs significantly more to repair than addressing the underlying issue promptly.

Power Outage Survival Strategy

During electrical outages, your grinder pump stops working while your home continues generating wastewater. Unlike gravity systems, you lose both pumping capability AND alarm functionality during outages—creating a silent failure scenario.

Critical Water Usage Restrictions

- Limit toilet flushing to absolute necessities

- Avoid dishwashing and laundry completely

- Take quick “navy showers” (wet down, turn off water, soap up, rinse quickly)

- Use bottled water for drinking and cooking to minimize wastewater

The holding tank provides only limited storage—typically several hundred gallons. Continued normal water usage during extended outages will exceed capacity, causing sewage backup into your home before power returns.

Extended Absence Preparation Checklist

For vacations longer than seven days, follow this specific preparation sequence to protect your system:

- Run an indoor faucet for 10 minutes (or until 30 gallons flow through the system)

- Verify pump activation by listening for the distinctive grinding sound near the station

- Turn off the faucet once pump activates—it will continue running until the tank empties

- Leave electrical power connected to maintain heating elements and alarm functionality

This process replaces wastewater with clean water, preventing odor development and reducing the risk of component damage during idle periods. The internal heating element prevents freezing during cold weather, and the alarm system remains functional to notify you of plumbing failures while you’re away.

Professional Service Cost-Saving Strategies

Understanding service pricing helps you make smart maintenance decisions and avoid overpaying:

| Service Type | Standard Hours | After-Hours |

|---|---|---|

| Service Call | $150 | $258 |

| Capacitor Replacement | $53 | $53 |

| Fuse Replacement | $38 | $38 |

| Grinder Station Pumping | $193 | $193 |

Consolidate multiple services into single visits—only one service call fee applies per visit regardless of how many components need replacement. Schedule routine maintenance during standard business hours to save up to $108 per service call compared to emergency rates.

Daily Habits That Extend Pump Lifespan

Incorporate these simple practices into your routine to prevent 90% of common grinder pump failures:

- Never pour grease down drains—dispose of cooking fats in sealed containers

- Direct downspouts away from the pump station (minimum 10-foot distance)

- Label your breakers clearly so anyone in your household can reset them

- Perform monthly visual inspections of the control panel and surrounding area

- Keep records of maintenance activities and repair dates

These small habits cost nothing but prevent thousands in potential damage. The most reliable grinder pump systems belong to homeowners who treat maintenance as routine rather than reactive.

Final Maintenance Checklist Before Winter

As temperatures drop, complete these essential preparations to prevent freezing damage:

- Verify the tank lid seal is intact with no cracks or gaps

- Confirm the internal heating element is functional (if equipped)

- Clear leaves and debris from the vent pipe on top of the station

- Ensure snow removal equipment won’t damage the station during winter storms

- Double-check that downspouts direct meltwater away from the station

Cold weather failures often occur because homeowners neglect these simple precautions. Taking 15 minutes now prevents emergency service calls during freezing temperatures when rates are highest.

Smart maintenance saves money and prevents disasters. By following these specific, actionable steps, you’ll avoid costly emergency repairs, extend your grinder pump’s lifespan, and protect your home from sewage backups. The difference between problem-free operation and constant failures comes down to consistent, proper maintenance—starting today.