Your ears might be ringing after just 30 minutes of operating a standard angle grinder, but did you know this isn’t just uncomfortable—it’s dangerously close to permanent hearing damage? Grinder noise levels consistently rank among the top occupational hazards in Australian metal fabrication shops, foundries, and manufacturing facilities, putting workers at serious risk of noise-induced hearing loss that develops silently over time. This comprehensive guide reveals exactly how different grinders measure on the decibel scale, what Australian regulations require for compliance, and most importantly—the practical control measures you can implement immediately to protect your team while keeping production flowing.

Many workshop managers operate under a dangerous misconception: if workers aren’t complaining about noise, everything must be fine. The harsh reality is that noise-induced hearing loss progresses gradually, often without noticeable symptoms until significant damage has already occurred. A typical angle grinder operating at 100 dB(A) can exceed safe exposure limits in under two hours, yet many workers endure daily exposure without adequate protection. By understanding the specific noise characteristics of your equipment and implementing the proven control strategies outlined below, you’ll not only comply with legal requirements but create a safer, more productive work environment where your team can thrive for years to come.

How Australian Regulations Define Dangerous Grinder Noise Levels

WorkSafe Victoria’s Occupational Health and Safety Regulations 2017 establish two critical thresholds that determine whether your grinder noise levels require immediate action. The first limit sets an 8-hour average exposure maximum of 85 dB(A), measured precisely at the worker’s ear position. This seemingly moderate number represents the threshold beyond which permanent hearing damage becomes increasingly likely with regular exposure. The second, equally important threshold establishes a peak noise limit of 140 dB(C)—designed to prevent immediate damage from sudden, intense noise bursts that can rupture eardrums even during brief exposure.

Why Hearing Protection Doesn’t Count Toward Compliance

Here’s what most workshop managers get wrong: when determining regulatory compliance, you cannot factor in the effect of hearing protection devices like earplugs or earmuffs. This regulatory requirement forces you to address noise at the source rather than relying on personal protective equipment as your primary solution. Your baseline noise measurements must demonstrate compliance even without workers wearing hearing protection—meaning if your angle grinder operates at 95 dB(A) during an 8-hour shift, you’re already exceeding legal limits regardless of what ear protection you provide.

When You Must Conduct Professional Noise Assessments

Your legal obligation to assess grinder noise levels kicks in when uncertainty exists about whether exposure exceeds or may exceed the 85 dB(A) threshold. This typically requires calibrated sound level meters worn by workers during representative tasks, not casual measurements taken near equipment. The assessment must account for all noise sources in the work environment—including multiple grinders operating simultaneously—as combined noise creates exposure levels far higher than any single source would suggest.

Angle Grinders vs. Bench Grinders: Measured Noise Output Differences

Not all grinders create equal noise hazards. Understanding the specific decibel ranges for different equipment types helps you prioritize control efforts where they’ll have the greatest impact on worker protection.

Why Hand-Held Angle Grinders Pose the Greatest Risk

Hand-held angle grinders generate the most dangerous noise levels in typical workshops, ranging from 90 to 115 dB(A) depending on several critical factors. Larger 9-inch grinders used for heavy steel cutting operate at the upper end of this spectrum, while smaller 4½-inch models for light finishing work produce relatively lower—but still hazardous—noise levels. The real danger comes from operators holding these tools directly next to their ears during use, maximizing sound exposure while creating a false sense of security since the grinding action itself masks the true noise intensity.

Critical risk factors that increase angle grinder noise:

– Dull or damaged grinding discs requiring more force

– Improper disc alignment causing vibration

– Grinding harder materials like stainless steel versus mild steel

– Operating at maximum RPM without proper technique

Bench Grinders and Linishers: Hidden Exposure Risks

While bench-mounted grinders and linishers typically produce lower noise levels (88-95 dB(A) range), their fixed workstation locations create unique exposure challenges. Workers often spend extended periods at these machines—sometimes entire shifts—resulting in cumulative exposure that exceeds safe limits despite the seemingly moderate decibel readings. The consistent, sustained nature of this noise exposure causes more insidious hearing damage than intermittent high-noise tasks because workers rarely recognize the gradual deterioration of their hearing.

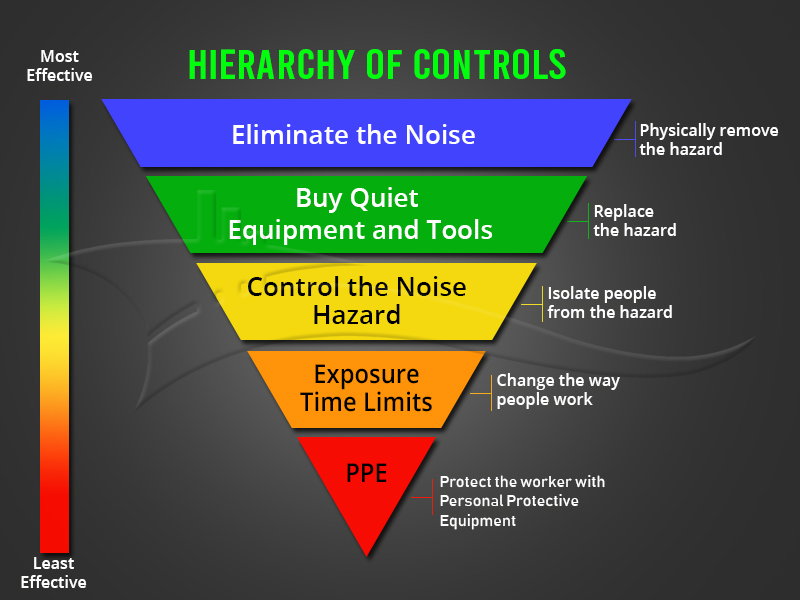

Implementing the 5-Step Hierarchy for Effective Grinder Noise Control

Australian regulations require employers to apply noise control measures following a specific sequence known as the hierarchy of control. This systematic approach ensures you address the hazard at its source rather than relying on less effective solutions.

Elimination: Removing Grinder Noise at the Source

The most effective noise control strategy eliminates the grinding operation entirely through smarter procurement and process design. Consider these proven elimination tactics:

- Purchase pre-cut or pre-fabricated materials that meet specifications without requiring on-site grinding

- Implement laser cutting technology for cleaner initial cuts that minimize finishing requirements

- Optimize foundry mould designs to reduce excess metal needing removal after casting

When elimination isn’t feasible, these strategies often reduce grinding time by 30-50%, significantly cutting overall noise exposure while improving productivity.

Substitution: Quieter Equipment That Maintains Productivity

Linishers frequently provide an excellent substitution option for traditional angle grinders in surface preparation tasks, typically operating at 88-95 dB(A) versus the 100+ dB(A) of comparable angle grinders. The substitution decision must balance noise reduction with quality requirements and production rates—never sacrifice safety for speed, but recognize that quieter equipment often improves work quality through more consistent material removal.

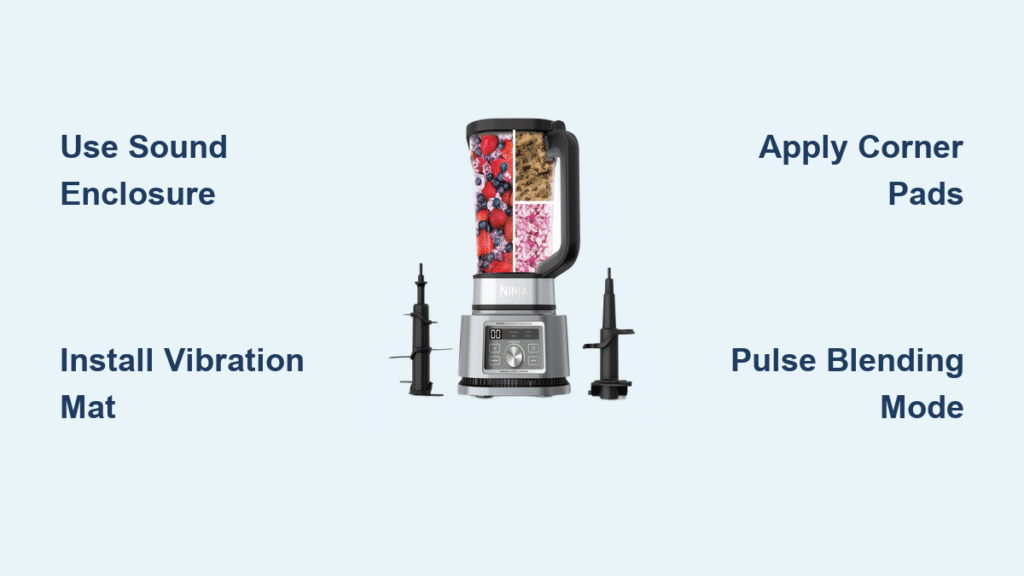

Engineering Controls That Deliver Measurable Results

Two engineering controls consistently deliver significant noise reductions in grinding operations:

- Rubber isolation mounts for bench grinders reduce vibration transmission by 2-4 dB when properly installed on resilient pads

- Acoustic partitions between grinding stations prevent noise compounding when multiple operators work simultaneously

These physical modifications require minimal operational changes but deliver permanent noise reduction that doesn’t rely on worker compliance.

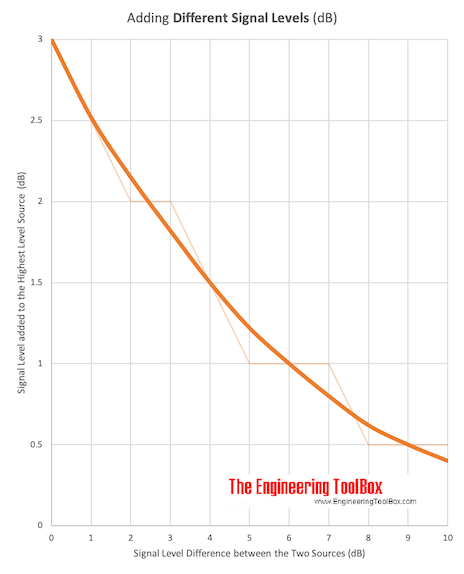

Why Two Operating Grinders Create More Than Double the Noise Hazard

Understanding how noise combines in your workspace is critical for accurate exposure assessment. When two grinders each producing 100 dB(A) operate simultaneously, the combined noise level reaches approximately 103 dB(A)—not 200 dB(A) as many mistakenly assume. This logarithmic addition means each doubling of noise sources increases exposure by only 3 dB, but even this seemingly small increase represents a dangerous exposure escalation:

- 85 dB(A) = Maximum 8-hour exposure limit

- 88 dB(A) = Maximum 4-hour exposure

- 91 dB(A) = Maximum 2-hour exposure

- 94 dB(A) = Maximum 1-hour exposure

This compounding effect explains why staggering grinding operations across your facility or creating dedicated grinding zones significantly reduces overall worker exposure without requiring major operational changes.

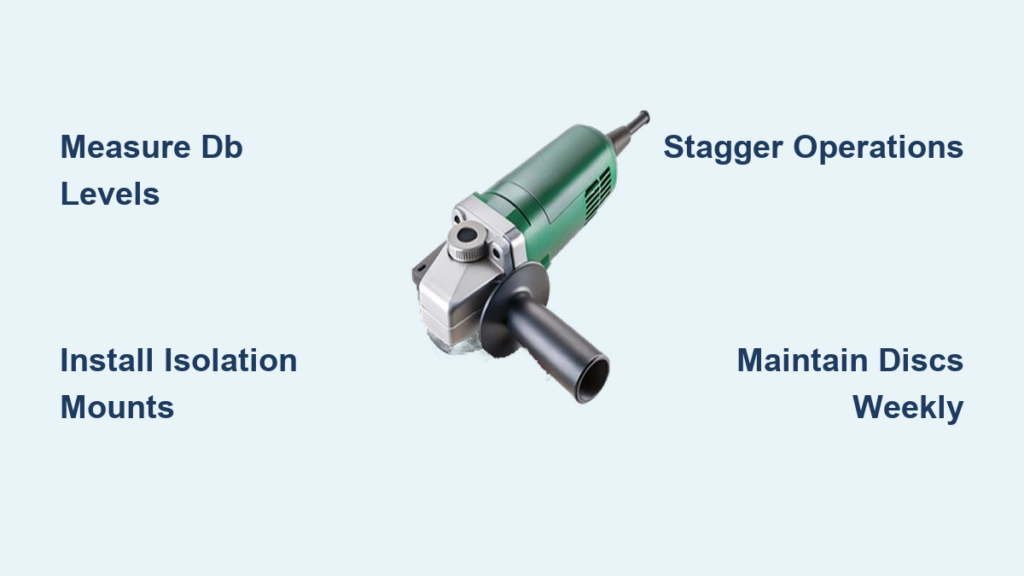

Weekly Maintenance Routines That Cut Grinder Noise by 3-5 dB

Proper maintenance directly impacts grinder noise levels in ways many workshops overlook. Implement these specific maintenance practices to reduce noise at the source:

- Sharpen grinding discs regularly – Dull discs require more force and create irregular vibration patterns that increase noise by 5-8 dB

- Inspect vibration isolation mounts weekly – Replace cracked or compressed rubber pads that have lost their noise-dampening properties

- Check disc alignment before each use – Misaligned discs create harmonic vibrations that significantly increase noise output

These simple maintenance steps not only reduce noise but also improve cutting quality and extend tool life, providing multiple operational benefits beyond hearing protection.

Critical Grinder Noise Specifications Every Workshop Manager Must Know

Keep this quick-reference guide visible in your workshop for immediate noise assessment:

- Legal exposure limit: 85 dB(A) average over 8 hours

- Immediate damage threshold: 140 dB(C) peak level

- Typical angle grinder noise: 90-115 dB(A) (varies by size and application)

- Bench grinder noise range: 88-95 dB(A)

- Effective noise reduction: 2-4 dB from proper isolation mounts

- Combined noise calculation: Two 100 dB(A) sources = 103 dB(A) total

Your 30-Day Plan to Achieve Grinder Noise Compliance

Start your noise control program immediately with these actionable steps:

Week 1: Conduct baseline noise measurements at operator ear positions during representative tasks

Week 2: Implement quick engineering controls—install isolation mounts and acoustic partitions

Week 3: Redesign workflow to stagger grinding operations and minimize concurrent use

Week 4: Train workers on proper grinding techniques that reduce noise and establish maintenance protocols

This systematic approach ensures you address grinder noise hazards at their source rather than relying solely on hearing protection. The most successful workshops combine multiple control measures from different hierarchy levels, creating layered protection that maintains compliance even as equipment ages or processes change. By taking these steps now, you’ll protect your workers’ hearing health while avoiding regulatory penalties and the hidden costs of noise-induced hearing loss claims—creating a safer, more sustainable operation where your team can work productively for decades to come.