Finding the perfect angle grinder can transform your DIY projects from frustrating struggles to smooth, efficient workflows. With so many models available—from compact 4.5-inch units to industrial 9-inch powerhouses—selecting the right one prevents wasted money and potential safety hazards. Choosing an angle grinder that matches your specific needs ensures you get the right balance of power, control, and durability for your tasks. This guide cuts through the marketing hype to show you exactly what matters when selecting this essential power tool, whether you’re tackling weekend home projects or professional fabrication work.

The wrong angle grinder can leave you battling kickback on delicate cuts or struggling with an underpowered tool on heavy jobs. Before spending your hard-earned money, you need to understand how disc size, power delivery, and safety features directly impact your results. By the end of this article, you’ll know precisely which specifications matter most for your specific applications and how to evaluate models against your actual needs.

Match Disc Size to Your Project Requirements

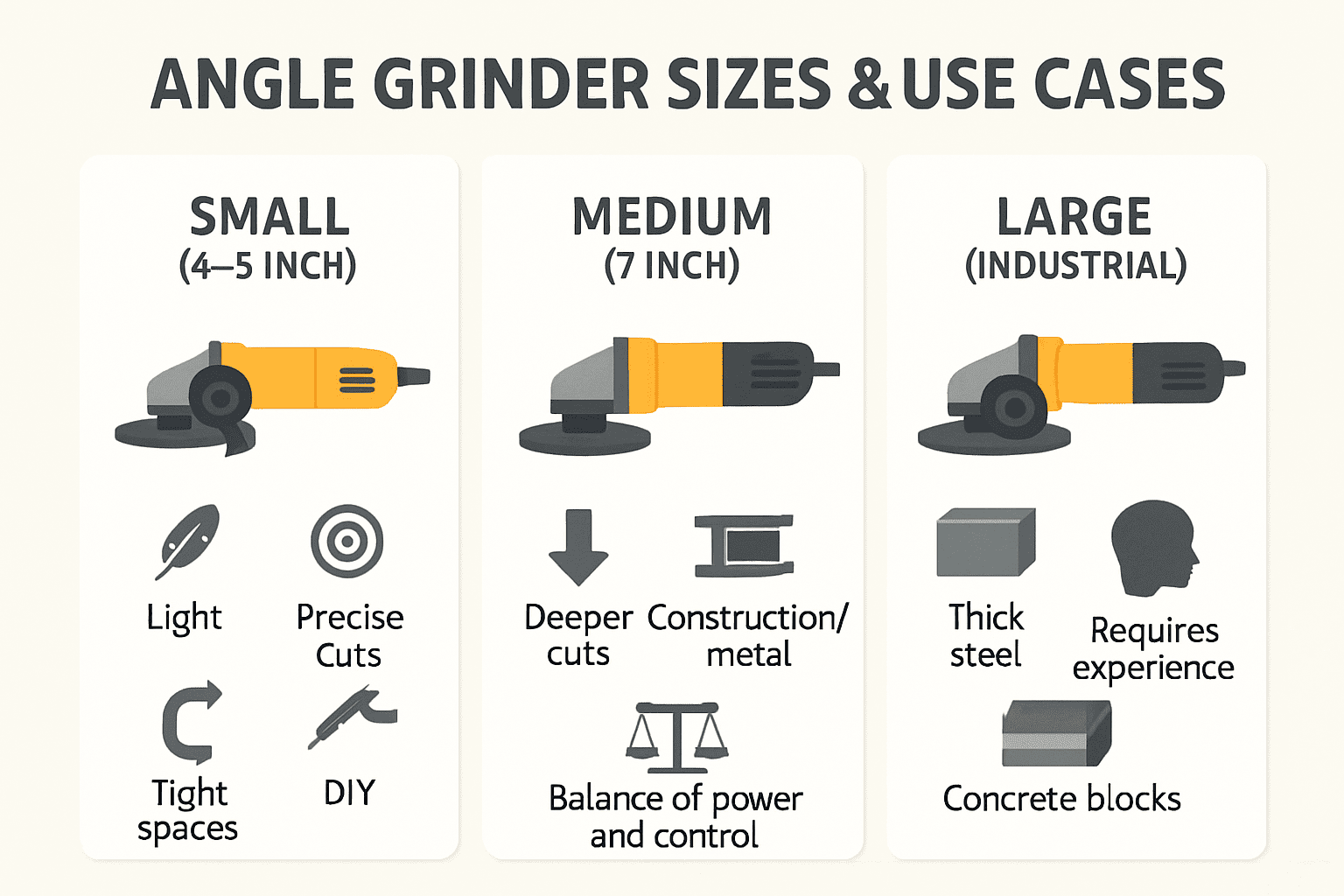

The disc diameter fundamentally determines your angle grinder’s capabilities, creating a critical balance between portability and cutting power that directly affects your work quality.

4.5-inch angle grinders deliver the ideal balance for most home workshops and light professional use. These compact tools navigate tight spaces easily while providing sufficient cutting depth for typical DIY metal projects. Their lighter weight reduces operator fatigue during extended sessions, and they generate less dangerous kickback than larger models—making them the safest choice for beginners. The widespread availability of affordable accessories for this size means you’ll never struggle to find the right disc for your task.

5-inch grinders bridge the gap between compact DIY tools and professional equipment. They remove material approximately 20% faster than 4.5-inch models while maintaining reasonable weight and control. Many metal fabricators prefer this size for general shop work because it handles continuous use without excessive arm strain. The slightly larger disc diameter provides better cutting efficiency on thicker materials while still fitting comfortably in most toolboxes.

How to Determine Your Ideal Disc Size

When considering which disc size you need, evaluate your three most common projects. If they involve cutting metal pipes, grinding welds, or removing rust from automotive parts, a 4.5-inch model likely suffices. For frequent work on structural steel, concrete surfaces, or heavy stock removal, consider stepping up to 5-inch or larger. Always prioritize the smallest size that can handle your toughest regular task—larger isn’t always better when control and safety are paramount.

6-inch and 7-inch grinders serve specialized needs where rapid material removal is the priority. These models excel at smoothing concrete floors, grinding down large weld seams, and cutting through thick steel plates. The larger disc covers more surface area per pass, significantly reducing project time on substantial jobs. However, the increased weight—often 25-50% more than smaller models—demands greater physical strength and wrist stability to maintain control.

9-inch industrial grinders belong exclusively to professional settings with demanding production requirements. Their massive cutting capacity enables extremely fast material removal but introduces substantial safety risks requiring experienced operators. These machines typically require 240-volt power sources and specialized safety training—making them inappropriate for most home workshops.

Evaluate Power Delivery Systems

Power specifications directly determine whether your angle grinder maintains consistent performance during demanding cuts or stalls when you need it most.

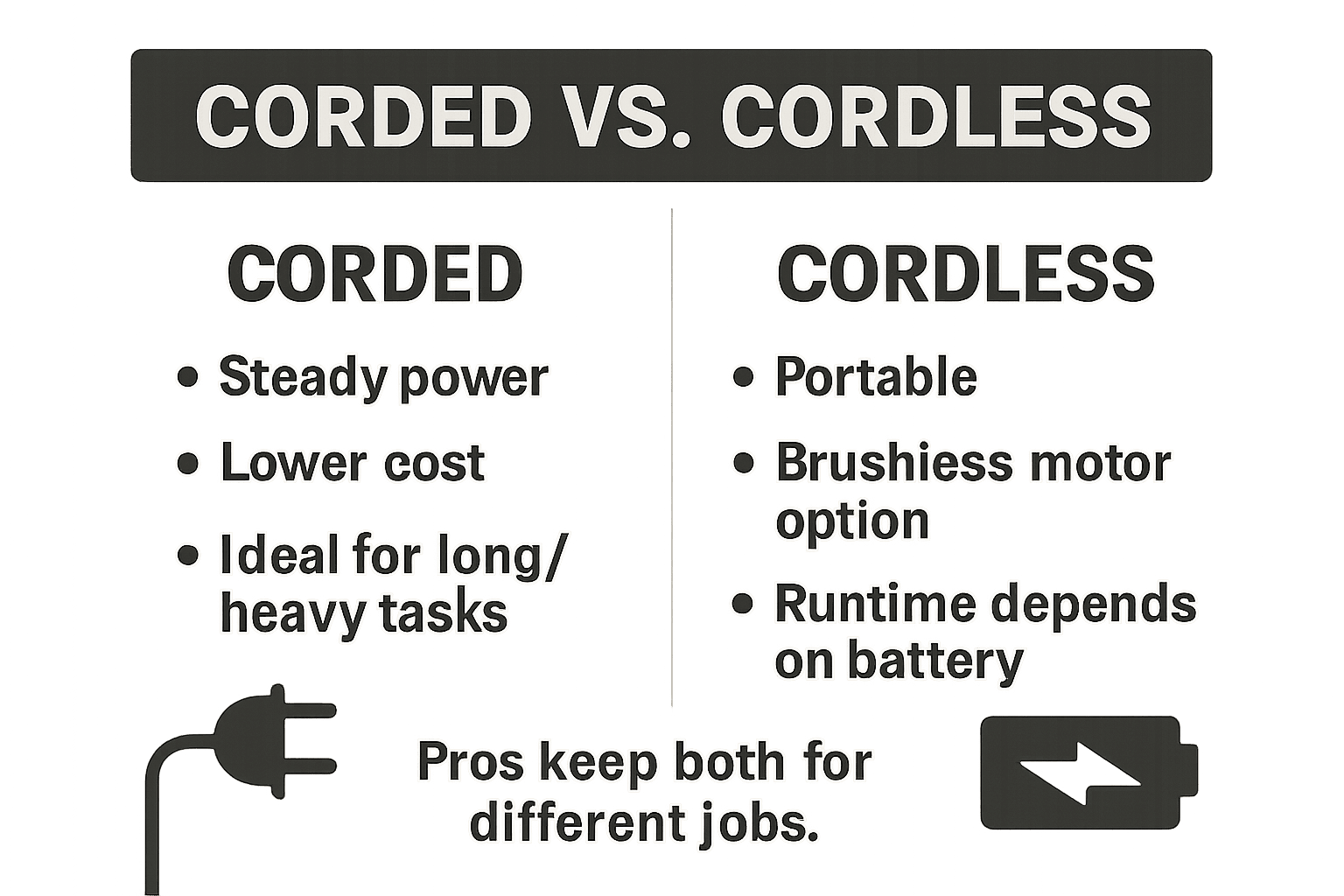

Corded angle grinders provide unlimited runtime and consistent power delivery essential for professional applications. Measured in amps, their power ranges from 6-amp lightweight models to 15-amp industrial machines. Higher amperage translates to greater torque and reduced slowdown under heavy loads. For serious metal fabrication or concrete cutting, select a model with at least 10 amps to prevent frustrating stalling during critical cuts. The tradeoff comes in reduced mobility—you’ll need proper extension cords and accessible power sources.

Cordless angle grinders offer unmatched portability but require careful battery consideration. Voltage options span from 18V to 60V systems, with higher voltages approaching corded performance. However, high-demand applications can drain even large-capacity batteries in 15-20 minutes. When choosing cordless, prioritize models compatible with your existing power tool ecosystem to maximize battery investment. Always purchase at least two batteries for continuous work, and verify the charger’s replenishment speed matches your workflow needs.

Why Motor Wattage Matters More Than You Think

Motor wattage provides the most accurate comparison between similarly sized grinders. A 1,500-watt model will consistently outperform a 900-watt unit of identical disc size, though build quality affects real-world results. Don’t chase maximum wattage numbers alone—evaluate user reviews for actual performance during sustained cutting tasks. Professional models often deliver more consistent power through superior thermal management, preventing the slowdown that occurs when cheaper tools overheat.

Prioritize Essential Safety Features

Angle grinders cause thousands of preventable injuries annually, making safety features non-negotiable rather than optional extras.

Paddle switches require deliberate two-handed activation, pressing the paddle with your palm while gripping the handle. This design prevents accidental startup when the tool is bumped or stored improperly. When released, the paddle immediately cuts power—unlike slide switches that require deliberate disengagement. Safety-conscious professionals specifically seek tools with this feature as their first line of defense against accidental operation.

Kickback protection systems use advanced sensors to detect sudden resistance spikes indicating disc binding. The best models stop the disc within 150 milliseconds of detecting dangerous kickback, dramatically reducing injury severity. While not foolproof, this technology provides critical protection, especially for overhead work or when using cutting discs near pinch points.

Electronic brakes stop the disc significantly faster than mechanical coasting, reducing the dangerous “spin-down” period where the tool remains hazardous after trigger release. This feature proves invaluable when making multiple cuts or working in tight spaces where disc contact could occur during normal handling.

Optimize for Your Work Environment

Ergonomics directly impact both safety and productivity—fatigue leads to loss of control, which invites accidents during critical operations.

Weight distribution affects how the tool feels during extended use. Quality grinders balance the motor mass to minimize wrist strain, with some models weighing up to 2 pounds less than competitors of identical disc size. For overhead work or all-day projects, prioritize models under 5.5 pounds for 4.5-inch grinders or 7 pounds for 5-inch units.

Grip design determines control precision during aggressive cuts. Look for textured rubber surfaces that maintain secure handling when hands become sweaty or oily. Adjustable handle positions—side-mounted, rear-mounted, or top-mounted—allow customization for left or right-handed operation and different cutting angles.

Anti-vibration technology reduces hand fatigue and prevents long-term nerve damage from chronic vibration exposure. Professional models incorporate counterbalance systems and rubberized housings that reduce vibration transmission by up to 40% compared to basic tools. If you plan regular use, this feature pays dividends in both comfort and safety.

Compare Value Across Price Tiers

Angle grinder pricing reflects clear quality distinctions that determine long-term value versus initial cost.

Budget models under $75 serve occasional DIYers with light projects but feature plastic components and brushed motors requiring frequent maintenance. These tools often lack critical safety features and may fail after minimal professional use. Consider them disposable tools for infrequent home maintenance rather than serious investments.

Mid-range grinders from $75-150 deliver the best value for dedicated hobbyists and part-time professionals. They typically feature brushless motors, metal gear housings, and meaningful safety systems. These models withstand regular use while offering professional-grade performance at reasonable prices. Brands like DeWalt, Makita, and Bosch dominate this segment with reliable warranty support.

Professional-grade tools above $150 justify their cost through extended service life and reduced downtime. With industrial bearings, advanced thermal protection, and comprehensive safety systems, they deliver consistent performance through daily professional use. The higher initial investment pays off through years of reliable service—critical when your livelihood depends on tool performance.

Match Your Grinder to Primary Applications

Your most frequent projects should dictate your angle grinder selection rather than chasing maximum specifications.

Metal fabricators need consistent low-RPM torque for stainless steel work to prevent discoloration and heat damage. Look for models with excellent speed maintenance under load and robust spark deflectors to protect your eyes during extended grinding sessions.

Concrete and masonry workers require sealed bearings and dust protection to withstand abrasive environments. Larger disc sizes (5-7 inches) remove material faster on surfaces like concrete floors, but ensure the model includes effective dust management to extend bearing life.

Automotive enthusiasts benefit from compact 4.5-inch grinders with variable speed control. Lower RPM settings prevent burning through thin sheet metal during bodywork, while higher speeds tackle rust removal efficiently. The smaller size provides better access to tight engine bay areas.

General DIYers should prioritize versatile 4.5-inch or 5-inch corded models with robust safety features. You don’t need maximum power, but reliable performance across cutting, grinding, and light polishing applications makes these the most practical choice for occasional home projects.

Essential Final Considerations

Choosing an angle grinder requires matching specifications to your actual needs rather than simply selecting the most powerful or cheapest option. For most home workshops, a 4.5-inch corded model with 9-10 amps provides the optimal balance of performance, control, and value. Professional users should prioritize brushless motors and advanced safety systems that justify higher costs through extended service life.

Never compromise on safety equipment—quality eye protection, hearing protection, and cut-resistant gloves form your essential defense against preventable injuries. The right angle grinder combined with proper safety gear ensures your projects remain productive and hazard-free for years to come. Test tools in person when possible, focusing on balance and trigger comfort, as these factors significantly impact your actual work experience.