Finding the perfect angle grinder can transform your metalwork, masonry, and fabrication projects from frustrating struggles to smooth, professional results. Whether you’re a weekend warrior tackling backyard renovations or a professional welder working on industrial jobs, selecting the correct tool directly impacts your efficiency, safety, and final outcome. The wrong angle grinder leaves you battling vibration, overheating, or inadequate power when you need it most. This guide cuts through the marketing noise to deliver practical, actionable advice on choosing an angle grinder that matches your specific needs, budget, and project requirements—ensuring you get professional results without overspending on features you’ll never use.

Many beginners make the costly mistake of purchasing whatever’s on sale at the big-box store, only to discover it lacks the power for serious metal cutting or the precision for delicate work. The good news is that by understanding just a few critical specifications and features, you can confidently select an angle grinder that becomes your go-to tool for years to come. Let’s dive into the exact factors that matter most when choosing your next angle grinder.

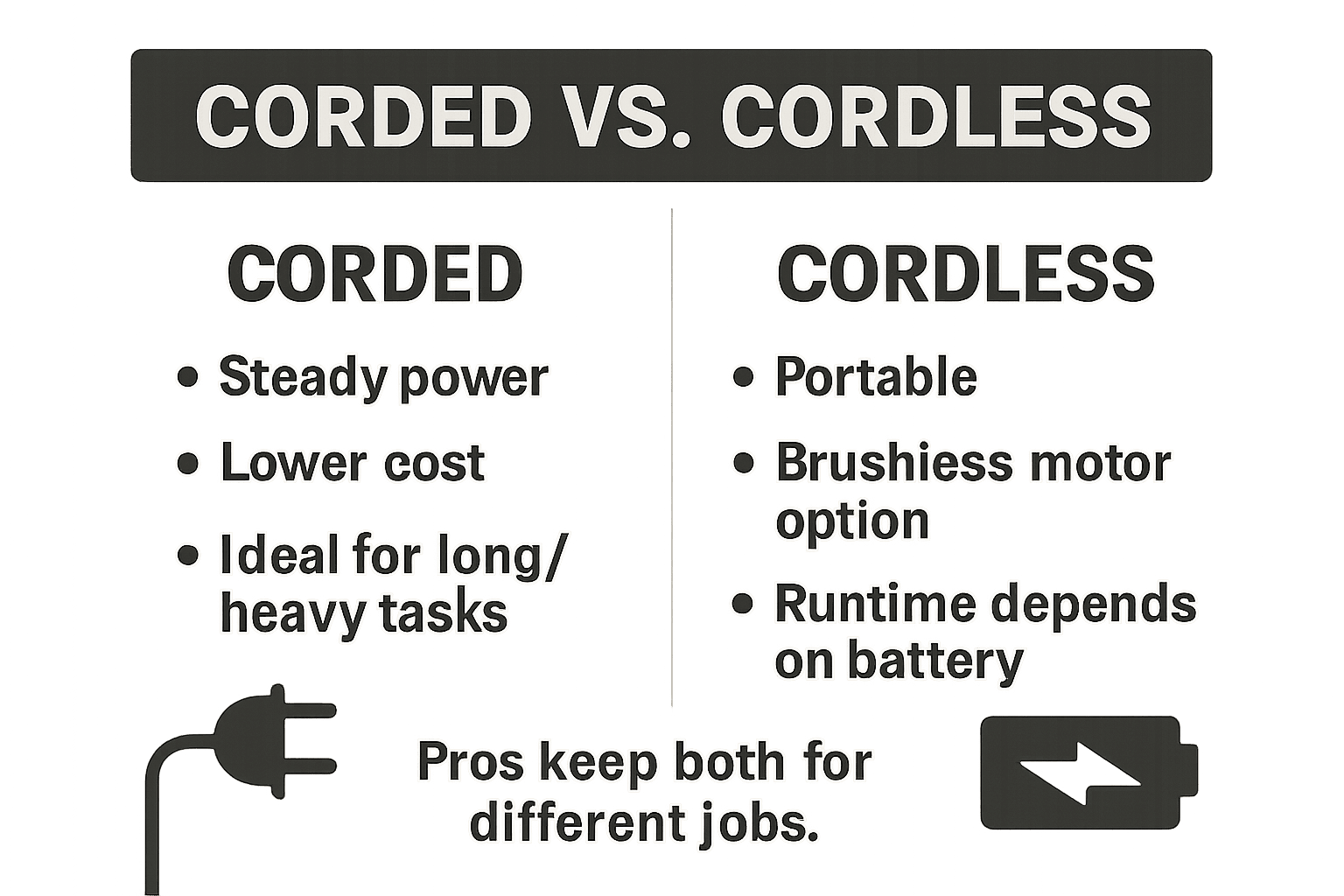

Corded vs. Cordless Angle Grinders: Which Power Source Fits Your Workflow?

Choosing between corded and cordless power determines your mobility, sustained performance, and where you can work effectively. This decision should come first in your selection process since it fundamentally shapes your tool’s capabilities.

Why Corded Models Dominate Professional Workshops

Corded angle grinders deliver uninterrupted power that maintains consistent performance during extended use—critical when grinding weld seams for hours or cutting through multiple metal sections. Electric models typically provide 5-15 amps of continuous power, translating to reliable torque that won’t diminish mid-task. Professional metal fabricators and contractors overwhelmingly choose corded tools for production environments where power outlets are accessible and downtime isn’t an option. You’ll pay less upfront for comparable power output compared to cordless models, but you must manage cord placement and avoid trip hazards. If your workspace has reliable power access and you regularly work on projects lasting more than 20 minutes, prioritize corded options for maximum value and performance.

When Cordless Freedom Justifies the Investment

Modern 18V and 20V MAX cordless angle grinders now deliver sufficient power for most DIY and light professional tasks while eliminating cord restrictions. These tools shine when working on remote job sites, outdoor projects, or in locations where running extension cords proves dangerous or impractical. Lithium-ion battery technology has dramatically improved runtime, though most users should expect 15-30 minutes of continuous heavy use per battery. Serious buyers should factor in the cost of at least one spare battery and a fast charger to minimize downtime. If you already own other tools on the same battery platform, the cordless option becomes significantly more cost-effective. For occasional home projects or mobile professionals who move between job sites frequently, cordless grinders provide unmatched convenience despite the higher initial investment.

Selecting the Correct Disc Size for Your Material and Workspace

Your angle grinder’s disc size directly determines cutting depth, maneuverability, and the range of tasks it can handle effectively. Choosing the wrong size leaves you either struggling with inadequate capacity or wrestling with an oversized tool in tight spaces.

4.5-Inch Grinders: The Ultimate DIY and Precision Work Tool

The 4.5-inch angle grinder represents the sweet spot for most homeowners and precision metalworkers, offering the best balance of power, control, and versatility. These compact tools provide approximately 1.25 inches of cutting depth—sufficient for cutting rebar, angle iron, and most structural steel sections encountered in residential projects. Their lighter weight (typically 4-6 pounds) reduces fatigue during overhead work or extended grinding sessions, while the smaller disc diameter enhances control for detail work like weld cleaning or contour grinding. If you primarily work on automotive repairs, small metal sculptures, or home improvement projects, the 4.5-inch model should be your first and possibly only angle grinder.

5-6 Inch Grinders: The Professional’s Versatile Workhorse

Five and six-inch angle grinders deliver the extra cutting depth and material removal rate needed for serious fabrication work while remaining manageable for one-handed operation. A 5-inch model provides about 1.75 inches of cutting depth, while 6-inch versions reach approximately 2.25 inches—making them essential for cutting thicker structural steel, removing substantial weld beads, or surface preparation on large components. These sizes dominate professional workshops where users regularly tackle diverse materials and require faster material removal than smaller grinders provide. The slight increase in weight (6-8 pounds) pays dividends in stability during aggressive grinding, though beginners may find them more challenging to control initially. For contractors and serious hobbyists who regularly work with thicker metals, these sizes represent the most versatile professional options.

Decoding Power Specifications: Amps, Volts, and RPM That Actually Matter

Understanding how power specifications translate to real-world performance prevents you from overspending on unnecessary power or buying an underpowered tool that struggles with basic tasks.

Amp Ratings That Match Your Workload Intensity

For corded angle grinders, amperage directly correlates with sustained power delivery during demanding tasks. Five to seven amp models work adequately for occasional light duty like rust removal or cutting thin sheet metal, but stall when encountering thicker materials. Eight to ten amp grinders represent the professional minimum for consistent performance across diverse applications, handling 1/4-inch steel plate with relative ease. Serious fabricators should consider 11+ amp models that maintain RPM under heavy load without overheating. Remember that higher amperage means increased weight and heat generation—balance power needs against your physical endurance and typical work duration.

RPM and Variable Speed: Control Beyond Raw Power

Most angle grinders operate between 8,500-12,000 RPM, but the best models offer variable speed control that dramatically expands their versatility. High RPM (10,000+) provides fast cutting through metal but generates excessive heat when working with aluminum or plastics. Medium speeds (6,000-8,000 RPM) excel at weld cleaning and finishing, while lower speeds prevent material warping during delicate work. If you regularly switch between cutting, grinding, and polishing applications, prioritize models with electronic speed control that maintains consistent RPM under load—this feature alone can justify the price difference for serious users.

Must-Have Safety and Performance Features You Can’t Afford to Skip

Beyond basic specifications, certain features significantly impact your safety, comfort, and the quality of your work—making them worth the investment even on budget-conscious purchases.

Electronic Brake Systems That Prevent Post-Release Accidents

Angle grinder kickback causes serious injuries when the disc catches and violently twists the tool from your grip. Modern grinders with electronic braking stop the disc within 2 seconds of trigger release—critical when working in confined spaces or overhead. This feature alone has prevented countless accidents and should be non-negotiable for any serious purchase, despite adding $15-30 to the price tag. Check for independent safety certifications like OSHA compliance to verify the braking system’s effectiveness.

Adjustable Side Handles That Reduce Fatigue and Improve Control

The best angle grinders feature multi-position side handles that mount at multiple points around the gear housing, allowing you to optimize grip position for different tasks. When cutting vertically, mount the handle at 90 degrees for maximum control; for horizontal grinding, position it at 180 degrees for better leverage. Rubberized grips with vibration dampening reduce hand fatigue during extended use—essential if you regularly grind for more than 15 minutes at a time. Never operate an angle grinder without the side handle properly installed; it provides critical secondary grip points that prevent loss of control during kickback events.

Matching Your Grinder to Specific Project Requirements

The perfect angle grinder depends entirely on what you’ll actually use it for—there’s no universal “best” model, only the best tool for your specific applications.

Metal Fabrication and Welding Applications

Welders and metal fabricators need consistent high-RPM performance for clean cuts and efficient grinding. An 8-10 amp corded 4.5 or 5-inch grinder with variable speed handles most welding tasks effectively, while thicker stock preparation benefits from 6-inch models. Prioritize tools with sealed switch housings that resist metal dust intrusion—a common failure point on budget models during extended welding prep work.

Concrete and Masonry Cutting Essentials

Cutting concrete requires different considerations than metalwork. You’ll need a grinder compatible with diamond blades rather than standard abrasive wheels, plus dust extraction capabilities to minimize silica exposure. While standard angle grinders can cut concrete with the proper blade, dedicated concrete grinders feature enhanced dust management and lower RPM settings optimized for masonry work. If cutting concrete represents more than 20% of your projects, consider a specialized tool despite the higher cost.

Smart Budgeting: What Price Tier Delivers the Best Value for Your Needs

Angle grinder pricing ranges from $30 consumer models to $400 professional tools, but the right investment depends on your usage frequency and project demands.

When Budget Models Actually Make Sense

If you’ll use the grinder fewer than 5 times per year for light tasks like cutting a few bolts or removing light rust, a $40-60 consumer model provides adequate performance. These tools typically feature 5-7 amp motors with plastic gear housings that won’t withstand daily professional use but work fine for occasional homeowners. Look for models with basic safety certifications and at least a 1-year warranty—even budget tools should meet minimum safety standards.

The Professional Sweet Spot: Mid-Range Tools That Last

For regular DIYers and professionals who need reliable performance without breaking the bank, $100-150 mid-range grinders deliver the best value. These models typically feature 8-10 amp motors with metal gear housings, electronic brakes, and vibration-reducing handles that significantly improve user experience. Brands like DeWalt, Makita, and Milwaukee offer professional-grade features in this range that will last for years of regular use. This investment pays off through reduced fatigue, faster work, and fewer replacements compared to constantly buying budget tools.

Making Your Final Selection: The Proven Decision Framework

Before purchasing, physically handle several models at your local tool dealer—comfort and balance vary significantly between brands and dramatically impact your experience. Test the trigger action, check weight distribution, and verify handle positioning options. The right angle grinder should feel like an extension of your arm, not a tool you’re constantly fighting to control. Prioritize tools with manufacturer service centers near you, as maintenance and repair accessibility often outweigh minor feature differences. Remember that the best angle grinder isn’t the most powerful or feature-rich—it’s the one that perfectly matches your specific needs, fits comfortably in your hand, and delivers reliable performance for years of actual use.