Grinding tools transform rough materials into precision components across workshops, factories, and home garages worldwide. Understanding the different types of grinder available prevents costly mistakes and wasted time when tackling projects requiring material removal, shaping, or finishing. Whether you’re cutting steel beams, sharpening chisels, or polishing automotive parts, selecting the correct grinder type directly impacts your project’s success, safety, and efficiency. This guide cuts through the confusion by detailing each grinder type’s specific capabilities, ideal applications, and critical selection factors—helping you make informed decisions that save time, money, and prevent dangerous tool misuse.

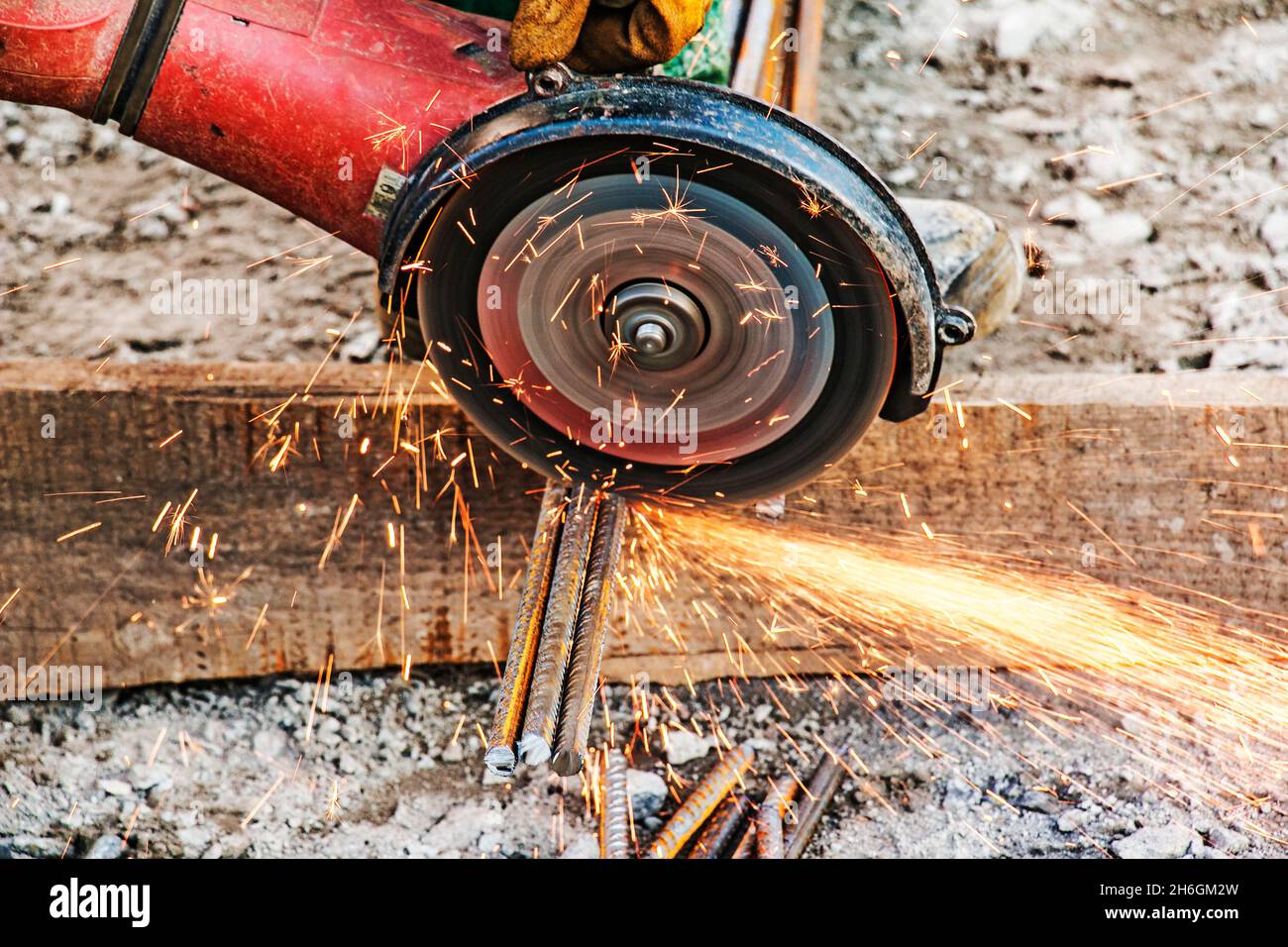

Angle Grinder Capabilities for Demanding Jobs

Angle grinders dominate construction sites and metal fabrication shops because their perpendicular disc orientation delivers unmatched versatility across cutting, grinding, and polishing tasks. These handheld powerhouses range from compact 4.5-inch models perfect for tight pipe work to industrial 9-inch variants capable of slicing through 3-inch steel plate. When your project requires cutting rebar on a skyscraper scaffold or removing weld seams on a custom motorcycle frame, the angle grinder delivers the power-to-size ratio no other grinder matches.

Why corded versus cordless matters for your project

Corded angle grinders maintain consistent RPM under heavy load, making them ideal for continuous cutting through thick materials where battery-powered models would drain rapidly. Cordless variants shine when working at heights without nearby outlets or on remote job sites, though you’ll sacrifice about 15-20% power compared to equivalent corded models. For weekend DIYers tackling occasional fence posts, a 20V cordless model provides sufficient power with convenient portability. Professional welders preparing joints daily will appreciate the relentless torque of a 15-amp corded grinder despite the power cord limitation.

Critical safety features you shouldn’t compromise on

Never operate an angle grinder without an adjustable guard positioned between you and the rotating disc—this single component prevents catastrophic injuries when discs shatter. Look for models with electronic brake systems that stop disc rotation in under 2 seconds after trigger release, crucial when working overhead. Vibration reduction technology isn’t just comfort-focused; prolonged exposure to standard grinder vibration can cause “white finger” syndrome within months of regular use. Spend extra for these features—they transform grinders from dangerous tools into precision instruments.

Bench Grinder Applications Beyond Basic Sharpening

Bench grinders deliver consistent results on repetitive sharpening tasks that handheld models struggle with, thanks to their rigid mounting and dual-wheel configuration. The coarse 60-80 grit wheel rapidly reshapes damaged tool edges, while the fine 120+ grit wheel polishes to a mirror finish—eliminating the need for separate sharpening stones. Woodworkers maintain chisels and plane blades with precise bevel angles, while mechanics restore screwdriver tips and drill bits to factory specifications using the adjustable tool rest.

How slow-speed bench grinders prevent heat damage

Standard bench grinders spinning at 3,450 RPM generate enough heat to soften tool steel edges during sharpening, defeating the purpose of your efforts. Slow-speed models operating at 1,725 RPM solve this problem by reducing friction heat, preserving the temper of high-speed steel tools. When sharpening carbide-tipped saw blades or precision lathe tools, this slower speed prevents micro-fractures that cause premature edge failure. The slight reduction in material removal rate pays dividends through significantly extended tool life.

Die Grinder Advantages for Precision Metalwork

Die grinders excel where angle grinders are too bulky and bench grinders lack portability—think inside engine blocks, along weld seams, or on intricate metal sculptures. Their pencil-like profile reaches areas no other grinder can access, while variable speed controls from 5,000-30,000 RPM allow delicate work on thin materials without burning through. Automotive fabricators use carbide burrs in die grinders to blend welds on roll cages, while jewelers polish precious metals with mounted rubber wheels at reduced speeds.

Pneumatic versus electric die grinders: The professional’s dilemma

Pneumatic die grinders deliver superior power-to-weight ratio and continuous runtime without overheating—critical for production environments. However, they require expensive air compressors and hoses that limit mobility. Electric models solve this with corded or cordless convenience but often lack the sustained torque for heavy deburring. For home shops with occasional use, a quality corded electric die grinder provides 80% of pneumatic performance at half the infrastructure cost. Production facilities processing hundreds of parts daily will justify the air system investment for pneumatic reliability.

Surface Grinder Precision for Critical Components

Surface grinders achieve flatness tolerances impossible with manual methods—think 0.0001″ across a 12″x24″ workpiece. This precision makes them indispensable for creating machine bases, gauge blocks, and hydraulic components where microscopic imperfections cause catastrophic failures. The grinding wheel’s cross-hatch pattern produces superior oil retention compared to milled surfaces, extending component life in high-friction applications like pump housings.

Horizontal versus vertical spindle surface grinders

Horizontal-spindle grinders dominate general-purpose workshops with their ability to handle large workpieces efficiently. Vertical-spindle variants with cup wheels excel at shallow grinding operations requiring minimal stock removal, such as preparing sealing surfaces on valve bodies. If your work involves mostly flat surfaces under 0.005″ depth of cut, the vertical model saves setup time. For deeper stock removal on irregular shapes, the horizontal spindle provides better wheel contact and chip clearance.

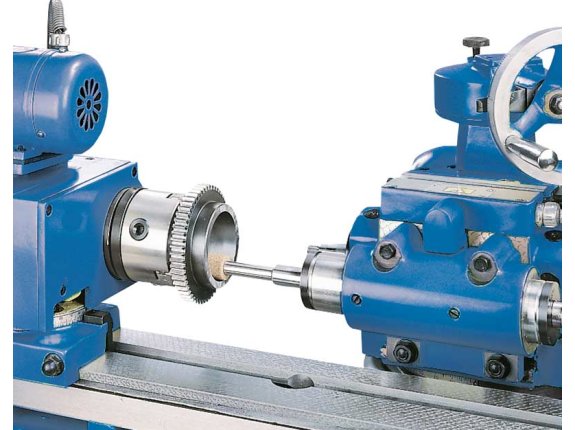

Cylindrical Grinder Solutions for Round Components

Cylindrical grinders solve the fundamental challenge of maintaining perfect roundness while removing material—critical for shafts, bearings, and hydraulic rods. External cylindrical grinders rotate workpieces against the grinding wheel, achieving concentricity within 0.0002″ even on 10-foot-long shafts. Internal cylindrical grinders tackle the opposite problem, grinding precise bores in engine blocks or hydraulic cylinders with equal precision using specialized small-diameter wheels.

Universal cylindrical grinders: The toolroom workhorse

Universal models combine external and internal grinding capabilities with adjustable headstocks that tilt for taper grinding. This versatility eliminates the need for multiple machines in low-volume shops producing custom parts. When machining a tapered valve stem with a precision bore at one end, a universal grinder completes both operations in a single setup—preserving critical alignment that separate machines would compromise. The higher initial cost pays for itself through reduced setup times and improved part accuracy.

Wet Grinder Benefits for Heat-Sensitive Materials

Wet grinders solve two critical problems: heat generation that warps workpieces and airborne dust that contaminates facilities. The continuous coolant flood reduces grinding temperatures by up to 70%, preventing thermal distortion in precision components and preserving material properties in heat-treated steels. In medical device manufacturing, this capability proves essential when grinding titanium implants that lose biocompatibility if overheated.

Benchtop wet grinders for home workshop use

Don’t assume wet grinding requires industrial equipment—compact benchtop models bring these benefits to DIYers. These units feature integrated coolant reservoirs and magnetic chucks that hold small workpieces securely during precision grinding. When sharpening carbide router bits or creating custom knurling tools, the wet grinder’s cooler operation prevents micro-fractures that cause premature tool failure. The initial setup seems messy compared to dry grinding, but the dramatically improved results and extended wheel life quickly justify the investment.

Safety Protocols Every Grinder Operator Must Follow

Grinder accidents often stem from complacency with basic safety protocols rather than complex equipment failures. Always perform the ring test on grinding wheels before mounting—tap the wheel gently with a non-metallic object and listen for a clear “ping” rather than a dull thud indicating internal cracks. Never exceed the wheel’s maximum RPM rating marked on its label, as centrifugal force can cause explosive failure at overspeed conditions.

Guard adjustment: The most overlooked safety step

Most angle grinder injuries occur because operators remove or improperly position the adjustable guard. Position the guard to cover the upper 75% of the wheel, creating a physical barrier between you and potential wheel fragments. When cutting horizontally, rotate the guard to protect your body from sparks and debris ejected downward. This simple step reduces injury severity by over 90% when wheel failures occur—a rare but potentially fatal scenario.

Maximizing Grinder Longevity Through Proper Maintenance

Grinder performance degrades gradually through neglect rather than sudden failure, costing you time and money through reduced efficiency. Clean air vents weekly with compressed air to prevent motor overheating—clogged vents are the leading cause of premature motor failure in corded grinders. For cordless models, store batteries at 40-60% charge in climate-controlled spaces; extreme temperatures permanently reduce lithium-ion battery capacity within months.

Wheel dressing techniques for consistent performance

A loaded, glazed grinding wheel works harder while producing poor results—a common frustration for beginners. Use a diamond dresser to restore the wheel’s cutting ability by removing the clogged surface layer and exposing fresh abrasive grains. Dress wheels before critical operations to ensure consistent material removal rates. For bench grinders, dress both wheels simultaneously using a tool rest-mounted dresser for perfect alignment. This 30-second maintenance step extends wheel life by 300% and dramatically improves grinding results.

Key Takeaways: Select angle grinders for versatile cutting/grinding, bench grinders for precision sharpening, die grinders for tight spaces, surface grinders for flatness-critical components, and cylindrical grinders for round parts. Always prioritize safety guards and wheel inspections regardless of grinder type. Invest in slow-speed or wet grinding options when working with heat-sensitive materials. Proper maintenance including regular wheel dressing and air vent cleaning extends equipment life significantly. Match your grinder selection to specific project requirements rather than opting for the most powerful model available—precision often trumps raw power in grinding applications.