Every time you fire up your angle grinder on metal, that dramatic shower of sparks isn’t just a visual spectacle—it’s a serious safety hazard you must manage. Angle grinders produce sparks from angle grinder operations due to the intense friction between the high-speed abrasive disc and the metal surface, creating temperatures exceeding 1,000°C. Whether you’re a professional welder or a DIY enthusiast tackling a home project, failing to properly address these sparks can lead to severe burns, property damage, or even catastrophic fires. Understanding why these sparks occur and how to control them isn’t optional—it’s essential for anyone who regularly works with this powerful tool.

The direction and intensity of sparks from angle grinder use depend on multiple factors including disc rotation speed (typically 5,000-10,000 RPM), the angle at which you hold the tool, pressure applied during cutting, and the specific material being worked. While you can’t eliminate sparks entirely when grinding metal, you can significantly reduce risks through proper technique, equipment selection, and safety protocols. This guide delivers actionable strategies to protect yourself and your workspace from the most common—and dangerous—consequences of sparks from angle grinder operations.

Why Your Angle Grinder Creates Dangerous Sparks

The sparks flying from your angle grinder result from small metal particles heating to extreme temperatures through friction and then rapidly oxidizing in the air. When the abrasive disc (typically made of silicon carbide or aluminum oxide) rotates at high speed against metal, it generates enough heat to ignite these tiny metal fragments. Silicon carbide discs work better with softer metals like aluminum, while aluminum oxide discs excel with ferrous metals—but both produce significant sparks when cutting metal.

Your disc size directly impacts spark danger—larger discs operate at lower RPMs but generate more momentum, potentially throwing sparks farther with greater force. This inherent spark production means proper safety measures are non-negotiable for every grinding session. Attempting to use an angle grinder on metal without acknowledging this fundamental characteristic puts you at serious risk of burns or fire.

How Disc Composition Affects Spark Behavior

Different abrasive materials create distinct spark patterns that reveal important safety information. Aluminum oxide discs grinding steel produce bright yellow sparks that branch at the ends, while silicon carbide discs working on aluminum create shorter, less intense sparks. The binder material holding abrasive particles together also influences spark temperature—some modern ceramic-bonded discs reduce frictional heat through greater lubricity, lowering spark temperatures by up to 200°C compared to traditional discs.

Critical mistake to avoid: Using the wrong disc type for your material significantly increases spark production and fire risk. Always match your disc composition to the metal you’re working with—never substitute when proper discs are unavailable.

Prevent Serious Burns from Angle Grinder Sparks

Sparks from angle grinder operations can cause surprisingly severe injuries despite their small size. When a spark contacts unprotected skin, it creates an immediate “snap” sensation followed by a sharp, localized burn. Areas with thinner skin—like your hands, neck, or face—experience more intense pain and damage. Even brief contact can cause second-degree burns, especially if multiple sparks hit the same spot during extended grinding sessions.

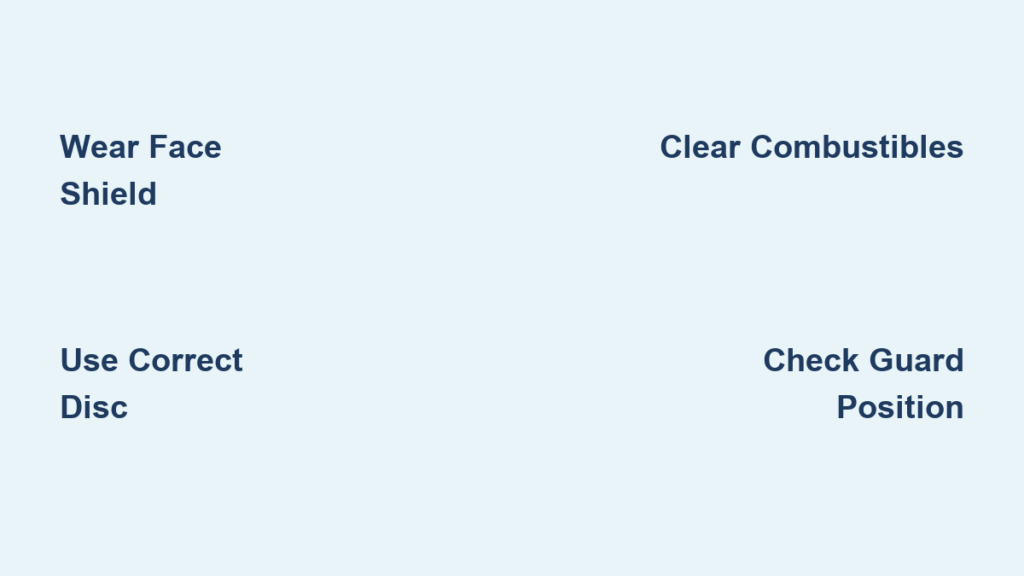

Essential Protective Gear Checklist

- Face protection: Wear safety glasses UNDER a full face shield—sparks easily bypass standard glasses

- Hand protection: Heavy-duty leather gloves rated for high heat (not cotton or synthetic alternatives)

- Body protection: Flame-resistant clothing or leather apron (regular work clothes can ignite)

- Foot protection: Steel-toed boots with leather uppers (sparks can burn through synthetic materials)

- Respiratory protection: N95 mask minimum when grinding metals that produce toxic fumes

Pro tip: Before starting, check your clothing for loose threads or cuffs that could catch sparks and ignite. Tuck in shirt tails and roll up long sleeves to minimize exposed skin.

Slash Spark Production with These Techniques

Reducing sparks from angle grinder use starts with proper technique rather than special equipment. The most effective method involves controlling pressure—applying excessive force increases friction and heat, generating more sparks. Instead, use light, consistent pressure and let the disc cut at its natural pace. You’ll produce fewer sparks while achieving cleaner cuts and extending disc life.

Three Proven Spark-Reduction Methods

-

The tape trick: Wrap 3-4 layers of masking tape around your cut line, then cut through both tape and metal—the tape acts as a heat buffer reducing direct metal friction

-

Ceramic disc advantage: Switch to ceramic-bonded cutting discs that reduce particle temperature through improved lubricity (ideal for fire-sensitive environments)

-

Angle adjustment: Hold the grinder at a 15-30 degree angle to the workpiece rather than perpendicular—this directs more heat into the workpiece rather than creating airborne sparks

Time-saving shortcut: When working near flammable materials, dampen a fire-resistant blanket and drape it nearby—but never allow water contact with active grinding operations.

Critical Fire Safety Protocols for Spark Management

Angle grinder sparks can travel over 35 feet from the work area, creating a much larger danger zone than most operators anticipate. This extreme throw distance explains why hot work permits typically require a 35-foot radius clearance of all combustibles before grinding begins. Never assume sparks will stay contained near your immediate work area—especially when working at elevated positions where gravity increases travel distance.

Thermite Reaction Danger You Must Know

The most catastrophic fire risk occurs when aluminum and steel particles mix in your work area. Aluminum dust combined with iron particles can trigger a thermite-like reaction when exposed to grinding sparks, generating temperatures exceeding 2,500°C—hot enough to melt through concrete. Always thoroughly clean your workspace between different metal grinding operations to prevent this deadly combination.

Real incident example: A metalworker suffered severe hand burns when grinding steel near previously ground aluminum dust—the resulting thermite reaction created an instant white-hot flame despite his face shield being in place.

Proper Handle Position for Maximum Safety

Your angle grinder handle position significantly impacts both spark direction and kick-back control. The standard recommendation places the handle on the left side, positioning your body behind the guard and away from the primary spark stream. This configuration directs sparks to your right—away from your body—but some experienced operators reverse the handle to the right side for better spark deflection.

Kick-Back Prevention Techniques

- Always grind on the side of the disc that pushes the tool away from you during binding

- Maintain a firm two-handed grip with elbows slightly bent for shock absorption

- Position your body slightly off-center from the cutting plane (never directly behind the disc)

- Never force a binding disc—release pressure immediately and reposition

When a cutting disc binds in metal, the tool can violently jerk toward you at high speed, potentially causing severe injury regardless of spark direction. Proper handle positioning minimizes this risk while also directing sparks away from your body.

Special Environment Precautions to Avoid Disaster

Certain work environments require extreme caution when dealing with sparks from angle grinder operations. In explosive atmospheres—like chemical plants, grain facilities, or areas with flammable vapors—standard electric grinders pose unacceptable risks. These settings demand certified non-sparking pneumatic tools specifically designed to maintain operating temperatures near body temperature.

Mobile Worksite Safety Checklist

- Sweep all surfaces within 10 feet of your work area before starting

- Bring a portable fire extinguisher rated for metal fires (Class D)

- Designate a fire watch person if combustibles can’t be fully cleared

- Use spark curtains or fire-resistant barriers when working near structures

Critical reminder: Never grind near steel wool or fine metal mesh—the rapid oxidation can create sustained heat capable of igniting surrounding materials hours after your work session ends.

Long-Term Safety Habits That Save Lives

Consistent pre-work preparation forms the foundation of spark safety. Before every grinding session, clear your workspace of all combustible materials—including sawdust, paper, rags, and flammable liquids—to at least 35 feet from your work area. Sweep floors thoroughly to remove metal dust accumulation that could ignite from stray sparks.

Essential Pre-Use Inspection Routine

- Check disc for cracks, chips, or excessive wear (replace if damaged)

- Verify guard is properly positioned to deflect sparks away from your body

- Ensure all handles are securely attached and tightened

- Confirm power cord is undamaged with no exposed wiring

- Test emergency stop function if equipped

Pro tip: After finishing work, monitor your workspace for at least 30 minutes—delayed ignition from hidden sparks accounts for nearly 40% of angle grinder-related fires.

By implementing these specific techniques for managing sparks from angle grinder operations, you transform a potentially dangerous task into a controlled process. Remember that no single safety measure provides complete protection—effective spark management requires combining proper equipment, correct technique, environmental awareness, and consistent protective habits. When you respect the fire and burn hazards created by your angle grinder’s sparks while applying these practical solutions, you’ll work more safely and confidently on every metal grinding project.