Hand-held angle grinders spinning at thousands of RPM create serious injury hazards that demand strict safety controls—wheel fragments can become deadly projectiles traveling at 300+ miles per hour. The Occupational Safety and Health Administration’s specific grinder handle requirements under 29 CFR 1910.243 address critical safety features that protect workers from catastrophic injuries during grinding operations. Understanding these OSHA grinder handle requirements is essential for employers, safety managers, and operators who must comply with federal regulations while preventing accidents involving accidental activation, wheel fragmentation, and contact with moving components. This guide breaks down the specific regulatory mandates, explains their practical applications, and provides actionable steps for maintaining compliant and safe grinding operations across construction, manufacturing, and metalworking environments.

Why Your Grinder Must Have a Constant Pressure Switch

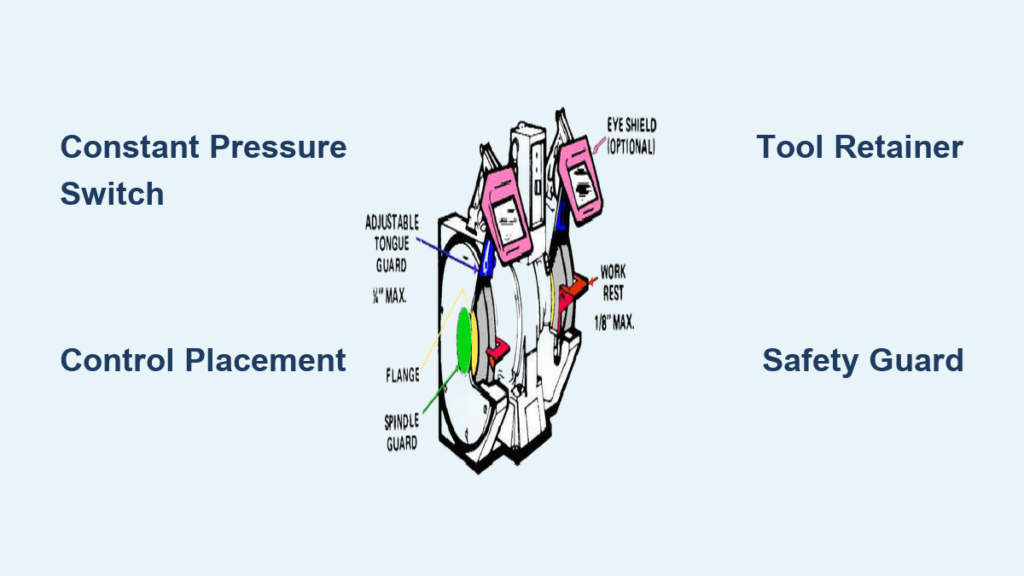

OSHA requires all hand-held powered angle grinders with wheels exceeding 2 inches in diameter to feature a constant pressure switch—a safety mechanism that immediately stops wheel rotation the moment you release pressure from the control. This non-negotiable requirement applies uniformly to horizontal, vertical, and angle grinders operating under the same size parameters, creating a direct safety relationship between your engagement and tool operation. Without this feature, a dropped or snagged grinder could continue spinning uncontrollably on the ground or against your body, causing severe lacerations or amputations within seconds.

When evaluating grinders for your worksite, verify these critical switch characteristics:

– Lock-on functionality must include single-motion turnoff—if your grinder has a lock-on feature (permitted but not required), the turnoff function must be achievable through one natural hand movement using the same fingers that activated the tool

– Switch placement must prevent accidental activation—controls should not align with natural hand resting positions during normal operation

– Immediate response time—the wheel must stop within 2 seconds of releasing the trigger

Many workplace accidents occur when operators modify or bypass constant pressure switches to reduce hand fatigue. This dangerous practice violates OSHA grinder handle requirements and dramatically increases injury risk—never disable or alter this critical safety feature. During equipment inspections, test each grinder’s constant pressure function by activating the tool and releasing the switch to confirm immediate shutdown.

How to Verify Proper Control Location on Your Grinder

OSHA regulation 1910.243(a)(2)(iv) explicitly states that “The operating control on hand-held power tools shall be so located as to minimize the possibility of its accidental operation.” This means your grinder’s trigger or switch must be positioned where your hand naturally rests during operation without creating risk of unintended activation when handling, transporting, or positioning the tool. Proper control placement prevents dangerous scenarios where a bump or drop could unexpectedly start the grinder.

What to Check During Equipment Inspections

When evaluating grinders for compliance with OSHA grinder handle requirements, look for these specific control placement characteristics:

- Trigger guards—physical barriers preventing accidental finger contact with the switch

- Recessed switches—controls set back from the handle surface requiring deliberate finger pressure

- Ergonomic positioning—triggers aligned with natural finger curl during grip, not palm rests

Common violations include modified triggers with removed guards, aftermarket handles that reposition controls dangerously, or using grinders with worn switches that activate with minimal pressure. If your operators report accidentally starting grinders while carrying them to work areas, your equipment likely violates OSHA requirements. Immediately remove non-compliant tools from service until proper controls are restored.

Pneumatic Grinder Tool Retention: Critical Safety Check

Pneumatic grinders present unique hazards due to compressed air power, requiring specific tool retention mechanisms that many workplaces overlook. OSHA mandates installation of a tool retainer on each pneumatic grinder that could eject the tool during operation without such a retainer. This requirement directly addresses high-velocity projectile hazards where air pressure could launch accessories if proper retention isn’t in place.

Essential Pneumatic Safety Verification Steps

Follow this 3-step verification process before using any pneumatic grinder:

- Inspect the retainer mechanism—confirm the tool has a functional retaining ring or collet system that physically prevents accessory ejection

- Check hose integrity—examine all air hoses for cracks, abrasions, or damage that could cause sudden pressure loss

- Verify connection security—ensure all couplings and fittings are properly seated with safety clips engaged

Additionally, all pneumatic hoses and connections must be specifically designed for the pressure and service they encounter. Using standard air hoses not rated for grinding equipment creates unacceptable risks of hose rupture or connection failure. Replace worn components immediately—don’t wait for visible damage as internal deterioration may already compromise safety.

Safety Guard Requirements for Different Grinder Types

OSHA’s guard specifications vary based on grinder type, creating common compliance confusion. Understanding these distinctions prevents dangerous misapplication of guards and ensures proper worker protection during different grinding operations.

Right Angle and Vertical Grinder Guard Specifications

For right angle head or vertical portable grinders, OSHA limits maximum angular exposure of the grinding wheel periphery to 180 degrees—meaning no more than half the wheel circumference should be exposed during operation. The guard must always be positioned between you and the wheel, creating a protective barrier that intercepts fragments if wheel breakage occurs. Crucially, the guard must be adjustable to redirect broken wheel pieces away from your position, not just provide passive containment.

Horizontal Grinder Guard Requirements

Horizontal portable grinders follow different rules—they must enclose the top half of the wheel at all times without exception. This requirement recognizes that horizontal orientation creates different exposure patterns requiring more comprehensive upper-wheel protection. The guard design must maintain continuous enclosure regardless of the tool’s position or your manipulation angle during grinding.

How to Properly Mount and Inspect Grinding Wheels

Before mounting any abrasive wheel, conduct these critical safety checks to prevent catastrophic wheel failure during operation:

Mandatory Pre-Mounting Inspection Protocol

- Perform the ring test—suspend the wheel freely and tap it lightly with a non-metallic object; a clear ringing sound indicates integrity while a dead thud signals internal cracks

- Verify speed compatibility—confirm the grinder’s spindle speed does not exceed the maximum operating speed marked on the wheel

- Check mounting surfaces—ensure all contact surfaces of wheels, blotters, and flanges are flat and free of foreign matter

Wheel fitting requires precise dimensional relationships—OSHA specifies the machine spindle must be manufactured to nominal size plus zero minus .002 inch, while the wheel hole must be suitably oversized to assure safety clearance under operating conditions. Improper fitting creates dangerous stress concentrations that can cause wheel disintegration at high speeds.

Cup Wheel Protection: Three OSHA-Approved Methods

Cup wheels (Types 6 and 11) require specialized protection approaches. OSHA permits three compliant methods:

- Standard safety guards—meeting general requirements in paragraph (c)(1)

- Revolving cup guards—mounted behind the wheel that rotate with it, constructed from steel or equivalent material

- Alternative approved designs—providing equivalent protection levels verified by OSHA

Revolving guards must enclose the wheel sides upward from the back for one-third of the wheel thickness while maintaining clearance not exceeding one-sixteenth inch between wheel side and guard. Many workplaces violate OSHA grinder handle requirements by using cup wheels without proper specialized protection—always verify your cup wheel configuration matches one of these approved methods.

Electrical and Pneumatic Compliance Verification Checklist

Portable electric grinders must meet electrical requirements in OSHA subpart S, addressing critical safety elements:

- Grounding integrity—test ground continuity regularly

- Cord condition—replace frayed or damaged cords immediately

- Moisture protection—use GFCI protection in damp environments

For pneumatic systems, verify these critical elements during weekly inspections:

– Hose pressure rating—matches or exceeds maximum operating pressure

– Connection security—all couplings properly seated with safety clips

– Retainer functionality—tool retention mechanism operates correctly

Training Essentials for OSHA Grinder Compliance

Effective implementation of OSHA grinder handle requirements depends on operator competency. Before operating any hand-held grinder, workers must demonstrate understanding of:

- Constant pressure switch operation—why releasing the trigger must immediately stop the wheel

- Guard positioning requirements—how to adjust guards for maximum protection

- Pre-use inspection procedures—including the ring test and speed verification

Document all training sessions with content covered, attendees, and competency verification results. Conduct refresher training annually or whenever new equipment is introduced. When employees demonstrate unsafe practices—like disabling constant pressure switches or using improper guards—immediate retraining is required before they resume grinding operations.

Avoiding Common Compliance Pitfalls

Many workplaces violate OSHA grinder handle requirements through these preventable mistakes:

- Using wheels 2 inches or smaller without proper assessment—while smaller wheels have different requirements, they still require safety evaluation

- Removing guards for “better visibility”—this violates fundamental OSHA requirements regardless of operator preference

- Ignoring work-provided protection exceptions—only omit guards when the work itself genuinely provides equivalent protection

During internal safety audits, verify each grinder has intact safety features, proper guards for the application, and operators who understand why these requirements exist. Maintaining compliance isn’t just about avoiding OSHA penalties—it’s about preventing life-altering injuries that occur in milliseconds when safety systems fail. By implementing comprehensive safety programs addressing all aspects of OSHA grinder handle requirements, you protect workers while maintaining regulatory compliance and avoiding costly workplace incidents.