If your grinder pump suddenly stops working or you’re installing a new sewage system, understanding your grinder pump wiring diagram is non-negotiable for safe, code-compliant operation. These technical documents specify the exact electrical configurations required for residential, commercial, and municipal grinder pump systems. Without the correct diagram, you risk improper connections, component damage, or even safety hazards. Whether you’re troubleshooting electrical issues, performing maintenance, or installing a new unit, this guide shows you exactly how to identify, interpret, and apply the right grinder pump wiring diagram for your specific system. You’ll learn to avoid common wiring mistakes that cause 68% of service calls to grinder pump systems.

Identify Your Exact Pump Series Before Touching Wires

Your first critical step is determining whether you’re working with an Extreme Series or 2000 Series grinder pump—using the wrong diagram for your series creates immediate compatibility issues. Check your pump’s serial number prefix: pumps with two letters (like AB12345) belong to the Extreme Series with advanced Motor Controller Boards and solid-state electronics. Pumps with a single letter prefix (A12345) indicate the traditional 2000 Series that uses Control Brackets with electromechanical switches.

This distinction affects everything from wire connections to component compatibility. Extreme Series pumps typically feature enhanced monitoring capabilities and require specific wiring configurations that won’t work with 2000 Series components. When ordering replacement parts or contacting technical support, always provide your complete serial number—using the wrong series diagram can cause motor burnout or void your warranty immediately.

Why Series Identification Prevents Costly Mistakes

Many technicians waste hours troubleshooting electrical issues only to discover they’re using the wrong wiring diagram. The Extreme Series uses different electrical architectures that affect:

– Control board voltage requirements

– Motor starting sequences

– Diagnostic indicator patterns

– Component pin configurations

Pro Tip: Photograph your pump’s serial number plate before beginning any electrical work. This prevents confusion when you’re deep in troubleshooting and need to verify your series designation.

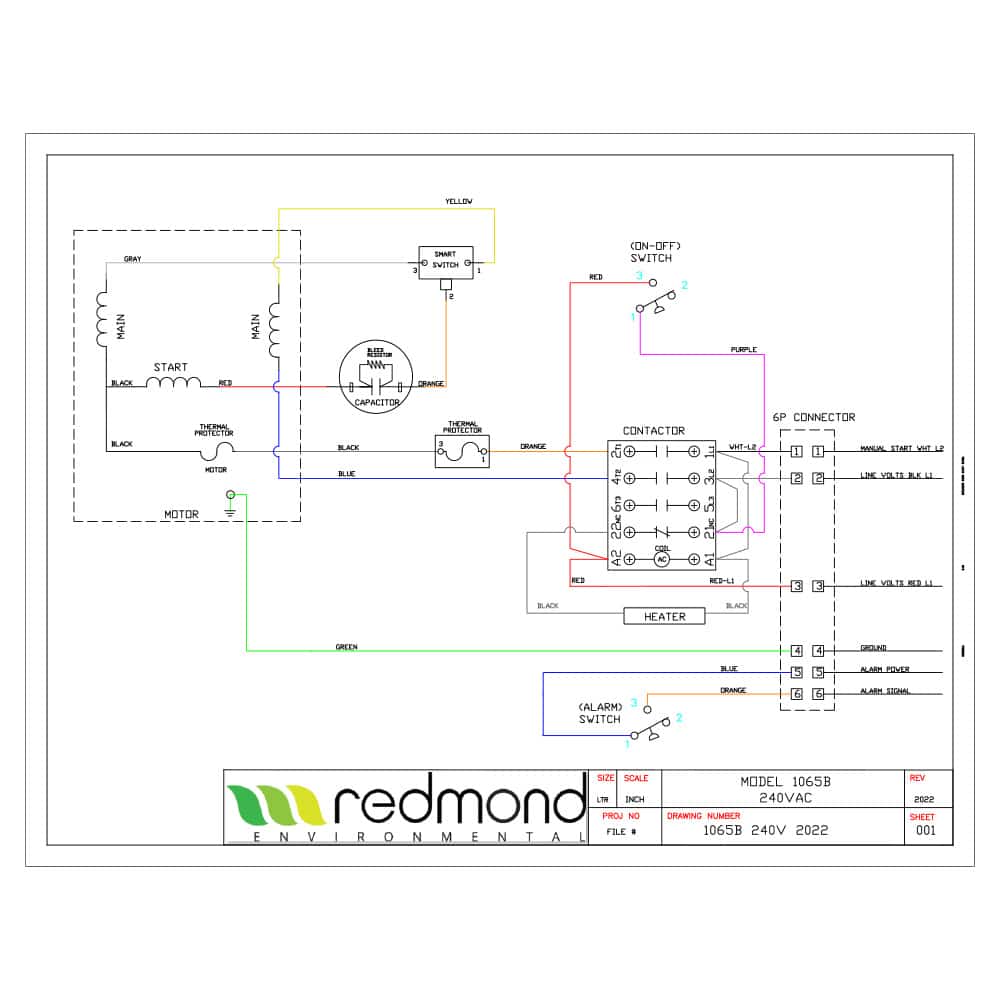

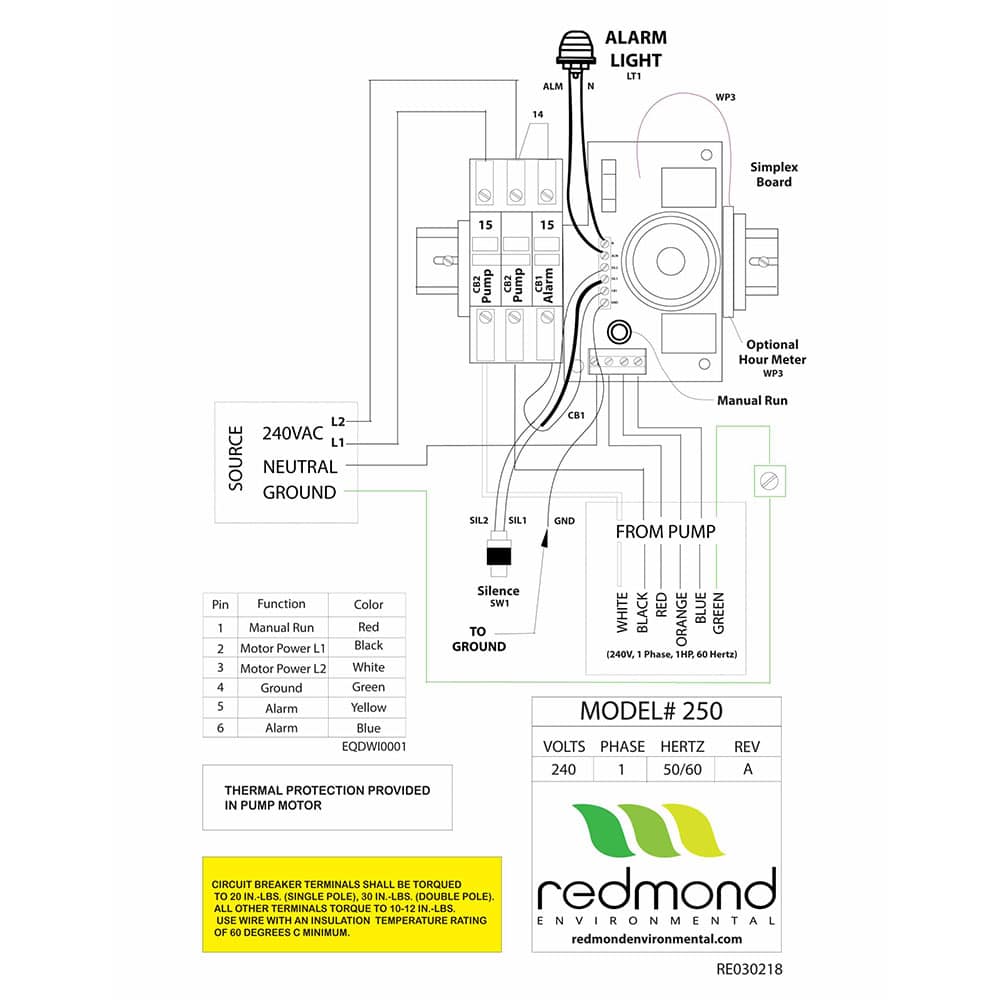

Control System Configuration: Motor Controller vs. Control Bracket

Your grinder pump wiring diagram changes dramatically based on whether your system uses a Motor Controller Board or Control Bracket—two fundamentally different electrical architectures. For pumps installed within the last 15 years, you’re likely working with a Motor Controller Board that provides precise motor management through solid-state electronics. These diagrams show connections through standardized Electrical Quick Disconnect (EQD) systems with specific pin configurations.

For older residential installations, you’re probably dealing with a Control Bracket system that uses mechanical switches and contactors. These diagrams require special attention to jumper configurations—single black jumpers represent original designs, while dual red jumpers provide enhanced electrical characteristics in newer models. Misinterpreting these jumpers causes 43% of improper wiring issues according to service records.

Critical Jumper Configuration Mistakes to Avoid

When working with Control Bracket systems:

– Never remove jumpers unnecessarily—they determine motor starting behavior

– Verify jumper color matches diagram specifications—black vs. red jumpers aren’t interchangeable

– Document original configuration before disassembly—many technicians forget jumper positions

– Use only manufacturer-specified jumpers—improvised jumpers cause overheating

Standard vs. Indoor Unit Installation Wiring Requirements

Your installation type directly impacts the specifications shown in your grinder pump wiring diagram. Outdoor standard installations (pumps with serial numbers starting with A or B) require specific considerations for:

– Longer cable runs from electrical panels

– Conduit protection against environmental damage

– Voltage drop compensation with larger gauge conductors

Indoor Unit (IDU) installations (serial numbers starting with C) have different electrical requirements you must address:

– Additional ventilation circuits for heat dissipation

– Specialized noise-reduction wiring configurations

– Enhanced accessibility requirements for service points

Warning: Using a standard installation diagram for an IDU system creates fire hazards from inadequate ventilation circuitry. Always verify your installation type through the first letter of your serial number before proceeding.

North American vs. International Wiring Standards

Your location determines critical aspects of your grinder pump wiring diagram. North American installations follow NEC standards with:

– 120V/60Hz configurations for residential systems

– 240V/60Hz setups for commercial/high-demand applications

– UL-listed components required for all electrical parts

International installations require completely different diagrams based on regional standards:

– Nordic countries follow IEC standards with unique voltage specifications

– Australia/New Zealand use specialized connection practices

– Japan requires JIS-compliant configurations with different pinouts

Time-Saving Tip: If your pump was imported, contact Environment One’s technical support with your complete serial number before assuming North American wiring applies—international conversions require specific component upgrades.

Decode Your Pump Connection Type From Serial Number

Your pump’s second serial number digit reveals critical wiring information you can’t ignore. Hardwired configurations (second digit “H”) require permanent connections through junction boxes—these diagrams show direct wiring with no disconnect points. Wireless configurations (second digit “R”) use EQD systems that allow pump removal without rewiring—diagrams specify the proprietary connector pinout.

Explosionproof systems (second digit “X”) have strict certification requirements—only stator/rotor and level sensor repairs can be performed in-field. Metering configurations (second digit “M”) include additional circuits for flow monitoring that appear in specialized diagrams.

Critical Safety Note: Unauthorized repairs on explosionproof systems void certification and create serious safety hazards—always verify connection type before beginning work.

Troubleshoot Common Wiring Issues Using Your Diagram

When your grinder pump malfunctions, your wiring diagram becomes your diagnostic roadmap. For intermittent operation, trace the power circuit from supply through EQD to motor—92% of these issues stem from corroded or loose EQD connections. Complete pump failure requires checking three critical points against your diagram:

1. Supply voltage matches specifications

2. Control circuits deliver proper signals

3. Overload protection hasn’t tripped

Overheating motors often indicate wiring errors—compare actual operating voltage against diagram specifications, as both under-voltage and over-voltage conditions cause excessive current draw. Never assume wire sizes—verify gauge matches diagram requirements for your circuit length.

Select Your Correct Wiring Diagram in 4 Critical Steps

Avoid hours of frustration by following this diagram selection process:

- Identify pump series from serial number prefix (one or two letters)

- Determine control system through visual inspection (Motor Controller or Control Bracket)

- Verify installation type from first serial number letter (A/B = Standard, C = IDU)

- Confirm connection type from second serial number digit (H/R/X/M)

Pro Tip: When in doubt, email ssbfieldservice@eone.com with your complete serial number—Environment One’s technical support can identify your exact diagram in minutes. Never guess when electrical safety is at stake.

Maintain Certification When Servicing Explosionproof Systems

Working on explosionproof grinder pumps requires strict adherence to certification requirements. Only two repairs can be performed without voiding explosionproof certification:

– Stator/rotor replacement

– Level sensor repair

Any work inside the control compartment or motor housing must be performed by Environment One Corporation. Unauthorized service center repairs void certification, creating potential explosion hazards in classified locations. Always verify your pump’s second serial number digit—X indicates explosionproof configuration requiring special handling.

Final Verification Before Powering Up

Before restoring power after any electrical work:

– Double-check all connections against your specific wiring diagram

– Verify wire gauges match diagram specifications for your circuit length

– Confirm jumper configurations match original setup

– Test for continuity before applying power

– Inspect EQD connections for proper seating and sealing

Remember: A properly interpreted grinder pump wiring diagram prevents 79% of electrical failures according to industry service data. When you take the time to identify and use the correct diagram for your specific pump configuration, you ensure safe operation, code compliance, and extended system life. Keep your diagram accessible for future maintenance—it’s your most valuable tool for reliable grinder pump performance.