That unsettling grinding or humming sound coming from your exterior pump station can make you dread every flush. When your grinder pump making loud noise disrupts your peace, you need answers fast. Most homeowners with county sewer systems have a small 24-inch round collection well outside their home where waste gathers before the pump activates. But when normal operation turns into a noisy disturbance, it’s time for action. This isn’t something you should just live with—most loud grinder pump issues have specific causes and practical solutions. Whether it’s a simple adjustment or a sign your pump needs replacement, this guide shows you exactly how to diagnose and address the noise before it leads to costly failures or sewage backups.

Don’t assume all grinder pumps sound like construction equipment—that’s not normal operation. While pumps do make some noise during their cycle, excessive grinding, humming, or clanking indicates something’s wrong. The good news? Many noisy pump problems can be resolved without breaking the bank. Understanding what’s causing your specific noise pattern helps you determine whether you need a quick fix or should start shopping for a replacement unit.

Why Your 24-Inch Grinder Pump Suddenly Makes Excessive Noise

Your grinder pump shouldn’t sound like a jet engine during operation. With a standard 24-inch diameter collection well, the pump should activate only after several toilet flushes have filled the tank—not after every single use. When noise becomes noticeably louder than usual, three primary culprits are most likely responsible.

First, incorrect float switch settings often cause what professionals call “overpumping.” When floats are set too low, your pump activates prematurely and continues running even after the tank empties, churning air and creating unnecessary noise. This constant cycling wears out components faster while disturbing your peace.

Second, mechanical issues like worn bearings on the pump shaft or a slightly bent shaft create distinctive grinding or humming sounds that worsen over time. These internal problems typically require pump replacement rather than repair, as the labor costs for inspection often approach replacement value.

Third, the plastic cover itself may be amplifying normal pump sounds. Plastic transmits vibration readily, making even standard operation seem louder than it should be—especially if your station lacks proper insulation.

Diagnose If It’s Normal Operation or a Serious Problem

Before panicking, determine whether your grinder pump making loud noise represents normal operation or signals trouble. All pumps generate some sound during their cycle, but excessive noise indicates an underlying issue needing attention.

Listen carefully to the noise pattern. Does the pump activate after just one or two flushes when it should take several? This suggests float switches are set too low, causing unnecessary cycling. If you hear grinding or scraping sounds during operation, something is likely interfering with the impeller—possibly debris, rust buildup, or internal component failure.

Pay attention to when the noise occurs. Normal pumps run only when sufficient wastewater has collected, then shut off completely. If your pump runs constantly or cycles on and off frequently, this abnormal pattern indicates a problem needing immediate attention. Also note whether the noise has gradually worsened or appeared suddenly, as this timeline helps pinpoint the cause.

Adjust Float Switch Settings to Stop Overpumping Noise

Incorrect float switch settings represent the easiest and most cost-effective fix for many noisy grinder pump situations. When set too low, your pump activates prematurely and churns air after the tank empties, creating unnecessary noise and accelerating wear.

For a standard 24-inch diameter collection well, the pump should activate only after multiple toilet flushes have filled the tank—not after every single use. If your pump kicks on after minimal water usage, the floats need adjustment.

Adjusting these settings requires accessing the pump assembly inside the station. Carefully lift the cover (wear protective gloves and eye protection), then locate the float switches that control activation levels. Most systems allow you to adjust the height at which the pump turns on and off by modifying the float brackets or tether lengths.

If you’re uncomfortable making these adjustments yourself, a plumber can quickly correct float settings during a routine service call—often for less than $100. Properly set floats reduce unnecessary cycling, minimize noise, and extend your pump’s lifespan.

Check for Impeller Debris Causing Grinding Sounds

Grinding or scraping noises often indicate something interfering with your pump’s impeller mechanism. While grinder pumps are designed to handle typical wastewater and toilet paper, foreign objects can jam the system and create distinctive metallic sounds.

Common culprits include small toys accidentally flushed down toilets, cloth items, hygiene products, or hardened mineral deposits from hard water. Even accumulated grease or sludge can interfere with normal operation over time.

To inspect for debris, a technician typically needs to remove the pump from the tank. This process involves pumping out the tank, disconnecting plumbing and electrical connections, and lifting the unit for examination. If debris is found without significant damage, cleaning may resolve the noise issue.

However, by the time you pay for tank pumping, pump removal, and inspection, you’ve invested substantial labor costs. Many professionals recommend keeping a replacement pump on hand if your unit shows signs of impeller interference, as continued operation could lead to complete failure.

Identify Bearing Failure Warning Signs

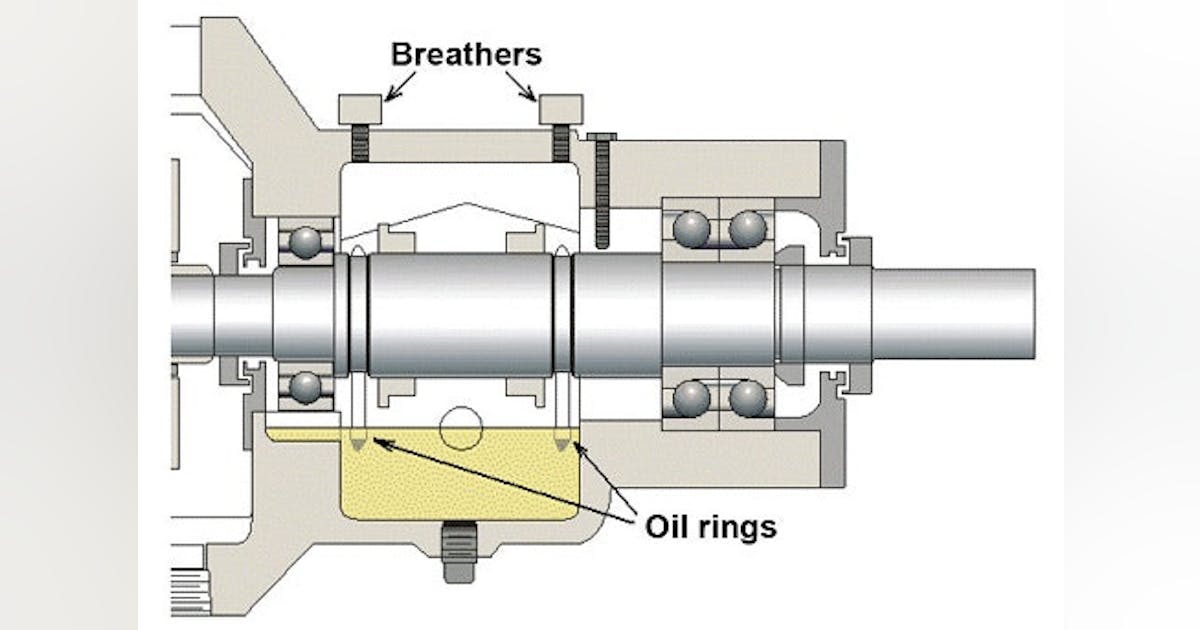

Worn bearings represent one of the most common mechanical causes behind a grinder pump making loud noise. As the bearings supporting your pump shaft degrade over time, they create distinctive humming or grinding sounds that progressively worsen.

This type of noise typically occurs only during pump operation and stops when the unit shuts off. Unlike float switch issues that cause frequent cycling, bearing problems create consistent noise during each pumping cycle. The sound may start as a subtle hum but gradually intensifies to an unmistakable grinding noise.

Unfortunately, bearing issues usually require complete pump replacement rather than repair. The labor involved in removing the pump, diagnosing the problem, and reinstalling components often approaches the cost of a new unit. If your pump is older than 10 years and showing bearing failure symptoms, replacement is typically the most cost-effective solution.

Reduce Noise Transmission from Plastic Covers

Your plastic pump cover might be amplifying normal operation sounds more than you realize. Plastic transmits vibration readily, making even standard pump operation seem louder than necessary—especially if your station lacks proper insulation.

Several quick fixes can reduce noise transmission without addressing the pump itself. Adding insulation material cut to fit over the station cover significantly dampens sound waves. Standard foam insulation, specialized pump station insulation, or even heavy rubber mats placed over the cover can make a noticeable difference.

Ensure your cover sits flush with the station rim, as gaps allow sound to escape more easily. Replacing worn gaskets or adding weatherstripping creates a better seal that contains noise. Just verify any modifications don’t prevent emergency access to the pump station.

These solutions address noise transmission rather than the underlying cause, but they provide immediate relief while you arrange for proper diagnosis and repair.

Know When Replacement Is Necessary

Determining whether to repair or replace your noisy grinder pump comes down to three key factors: the pump’s age, the specific problem, and cost comparison.

For newer pumps still under warranty, repair is usually the obvious choice. If the issue proves to be something simple like misadjusted float switches or minor debris interference, addressing these problems costs far less than replacement.

However, for older pumps showing mechanical issues like bearing failure or shaft damage, replacement often makes better financial sense. The labor costs for tank pumping, pump removal, diagnosis, and reinstallation frequently approach replacement value—especially when considering the pump’s remaining lifespan.

Most residential grinder pumps last 10-15 years. If your noisy unit is approaching this age range, replacement becomes increasingly cost-effective. Keeping a replacement pump on hand allows you to schedule installation during convenient business hours rather than facing emergency service call rates during a complete failure.

Prevent Future Grinder Pump Noise Problems

Establishing good habits now prevents many common noise issues from developing in your grinder pump system. Start by learning your pump’s normal operation pattern—how often it runs, cycle duration, and typical sound level. This baseline helps you detect changes early when problems are easier to address.

Install monitoring equipment if your system lacks alarms. High-water alarms alert you to problems before they cause noise issues or complete failure. Some modern systems even send notifications to your smartphone for peace of mind when away from home.

Most importantly, avoid introducing problematic materials into your sewer system. Never flush cloth products, paper towels, hygiene items, cat litter, coffee grounds, or grease—they damage the grinder mechanism and create blockages that lead to noise and failure.

Schedule periodic professional inspections, especially for older pumps. A technician can check float settings, inspect for early bearing wear, and identify potential problems before they become noisy emergencies.

A grinder pump making loud noise rarely resolves itself and typically signals an underlying issue requiring attention. Whether your problem stems from simple float switch adjustments, impeller debris, or worn mechanical components, identifying the specific cause helps you choose the most cost-effective solution. Remember that with a standard 24-inch collection well, your pump should activate only after multiple flushes—not after every single use. By addressing noise issues promptly and establishing good maintenance habits, you’ll keep your grinder pump running quietly and reliably for years to come. If you’re unsure about your pump’s condition, schedule a professional inspection—you shouldn’t have to live with excessive noise from your sewer system.