A grinder pump clogged with debris can quickly escalate from a minor inconvenience to a serious plumbing emergency. When your grinder pump loses its ability to process waste properly, you may face sewage backups into your home, foul odors throughout the property, and expensive emergency repairs. Understanding why these clogs occur, how to identify them early, and what steps to take for resolution can save you thousands of dollars while protecting your home from wastewater damage. This comprehensive guide walks you through everything from basic diagnosis to professional repair options, giving you the knowledge to address grinder pump clogs effectively and prevent them from recurring.

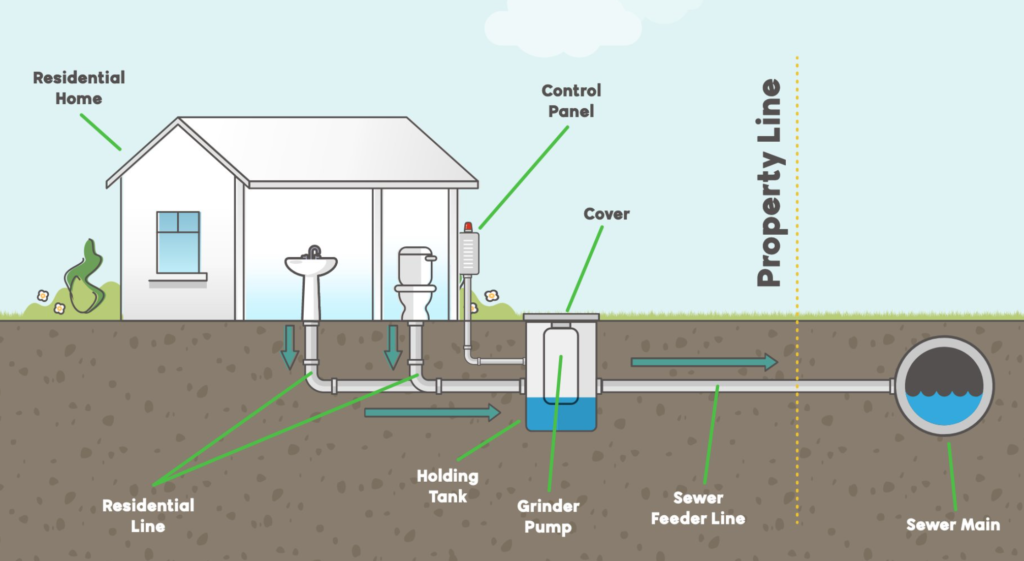

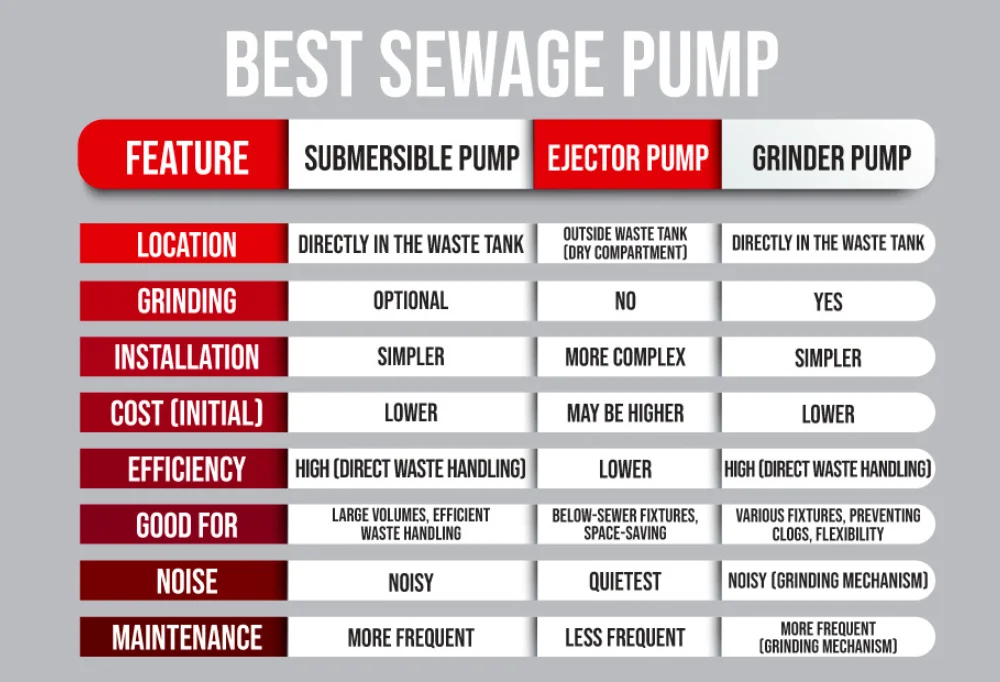

Grinder pumps serve as critical components in wastewater systems for homes and businesses where gravity cannot move sewage to the main sewer line or septic tank. These specialized devices grind solid waste into a fine slurry before pumping it through pressurized discharge lines, often over long distances or uphill terrain. Unlike standard sewage ejector pumps, grinder pumps feature cutting blades specifically designed to macerate solids that would otherwise cause immediate blockages. However, even these robust systems have limitations, and introducing inappropriate materials or neglecting maintenance can lead to clogs that disable the entire system.

Identify What’s Causing Your Grinder Pump Clog

Pinpointing the exact cause of your clogged grinder pump determines the most effective solution and prevents wasted effort on the wrong repair approach.

Foreign Objects Jamming the Grinding Mechanism

The overwhelming majority of grinder pump clogged emergencies stem from introducing inappropriate materials into the system. These pumps are engineered exclusively for human waste and toilet paper—everything else creates serious blockages. Wet wipes (even those labeled “flushable”) represent the most common culprit, as they maintain structural integrity when wet and accumulate within the pump chamber. Paper towels, feminine hygiene products, cat litter, and food scraps create similar problems. Professional plumbers routinely extract wet wipes, plastic remnants, and other non-biodegradable debris from jammed grinder pumps, often requiring either pump removal or directional reversal to clear the obstruction.

Grease Buildup and Clot Formation

Grease and oil create particularly stubborn clogs as they adhere to pipe walls and pump components, gradually building up layers that trap other debris. This leads to clot formation where larger debris gets stuck inside the grinder pump and adheres to the chamber walls. These clots catch additional items flowing through the system, progressively growing larger and significantly slowing operation. A distinctive whining or straining noise during operation often signals clotting, as the motor works harder than normal to push waste through the obstructed area. Professional cleaning is typically required before these clots cause complete system failure.

Discharge Line Blockages After Grinding

Discharge line clogs present unique challenges because they occur after the grinding process has been completed. Processed solids can “set up” or solidify in the discharge line, particularly if the pump has been inactive for an extended period. One common scenario involves solids hardening in copper discharge lines running approximately 100 feet from the grinder pump, creating a blockage so severe that even a new pump cannot clear it. The pressure created by the grinder pump against these set-up solids causes the motor to stall and stop turning. These blockages are especially problematic because they create a pressurized situation where the pump continues working against the obstruction rather than moving waste through the system.

Recognize Early Warning Signs of Clogging

Catching grinder pump problems early allows you to address clogs before they cause complete system failure or sewage backups into your home.

Performance Changes Requiring Immediate Attention

Pay attention to changes in your grinder pump’s normal operation patterns. Poor performance often indicates worn grinder blades or clogged components struggling to process waste efficiently. The pump may need to run longer than normal to clear the same amount of waste, or it may fail to completely process solids, leaving them in the holding tank. Constant running or frequent cycling represents another significant warning sign—when a grinder pump does not shut off properly or activates more frequently than its established pattern, it typically struggles against a blockage.

Strange noises during operation signal internal problems frequently related to clogs. While some operational noise is expected from grinder pumps, unusual sounds such as whining, grinding, or pronounced straining suggest the pump works against an obstruction. These sounds typically worsen as the clog grows larger and the motor strains harder.

Visual and Sensory Indicators of Trouble

Bad smells emanating from drains or the pump area indicate that waste is not moving properly through the system. While seals and gaskets can wear over time and allow odors to escape, persistent foul smells often point to a more serious blockage preventing appropriate waste transport. Visible leaks at connections or from the pump housing suggest worn components or pressure buildup from clogs damaging seals. Water backups into sinks, showers, or toilets represent a serious indication of grinder pump clogged failure requiring immediate attention. Your alarm panel, if properly configured, should alert you to rising water levels before backups occur.

Clear Common Grinder Pump Clogs Yourself

Some clogs can be addressed with basic troubleshooting before calling a professional, potentially saving you hundreds in service calls.

Fixing Float Switch Problems

Before assuming a physical clog, check your float switch—the component inside the tank that triggers the pump to activate. Turn off electricity to the pump at the breaker before opening the tank for inspection. Examine the float mechanism for grease coverage, debris accumulation, or any restriction in its movement. The float must move freely as water levels change. Cleaning a grease-covered float switch often resolves activation problems without requiring further intervention. This simple fix takes 15-20 minutes and prevents unnecessary service calls.

When Pump Reversal Might Work

Some grinder pumps can be reversed to clear minor jams, allowing the blades to rotate in the opposite direction and release trapped debris. This approach works best when the clog consists of material wrapped around the grinding mechanism rather than hardened in the discharge line. However, reversal is not a solution for all clogs and may cause damage if attempted on a severely compromised pump. Always consult manufacturer documentation before attempting this procedure, and consider professional help for pumps showing significant strain.

When to Call a Professional for Grinder Pump Clogs

Certain clog situations require professional expertise to avoid causing further damage or creating health hazards.

Discharge Line Blockage Solutions

For discharge lines that are essentially straight, professionals use commercial-grade snakes with sufficient cable length to reach and clear blockages. However, 100 feet or more of 1.5-inch pipe presents challenges, especially with multiple elbows. Video inspection equipment allows technicians to see the exact nature and location of the clog before attempting clearance. When snaking proves unsuccessful, mini-jetting introduces high-pressure water into the line to break up set-up solids. Some professionals recommend controlled carbon dioxide pressure as a safer option than compressed air to blow the line open.

Complete Pump Replacement Scenarios

If your grinder pump clogged situation has caused motor damage from straining, or if grinding blades are too worn for efficient processing, replacement may be necessary. Pumps requiring frequent clearing of the same recurring clogs likely have internal damage. Age also factors in—grinder pumps typically last 10 to 15 years with proper maintenance. When replacing, consider investing in a standard basin and pump installation rather than a prepackaged unit. While more expensive upfront, standard installations offer better reliability and easier maintenance access. Professional installation of a 240-volt grinder pump with alarm typically costs $10,000-$13,000, which should be weighed against the cost of repeated repairs.

Prevent Future Grinder Pump Clogs Completely

The most cost-effective approach to grinder pump clogged issues is prevention through proper usage and maintenance.

Strict Waste Disposal Guidelines

Implement and enforce a “toilet only” policy for your grinder pump system. Only human waste and toilet paper belong in toilets connected to grinder pumps. Everything else—including wet wipes (regardless of labeling), paper towels, feminine hygiene products, cat litter, grease, and food scraps—must go in the trash. Posting clear signage above toilets, particularly in commercial buildings or multi-family properties, helps ensure all users understand proper disposal. One effective commercial solution implemented by coffee shops—switching from paper towels to hand dryers—dramatically reduced clog problems.

Professional Maintenance Schedule

Schedule annual professional inspections for your grinder pump system, with more frequent service for commercial applications or systems with a history of problems. Professionals identify hidden issues during scheduled inspections and perform cleaning beyond homeowner capabilities. This preventative care extends pump life and significantly reduces emergency repair likelihood. Follow manufacturer recommendations for specific maintenance intervals, as many jurisdictions require periodic sewage pumping to prevent solid accumulation that leads to clog formation.

Proper Installation Best Practices

Ensure your grinder pump is buried deep enough to prevent freezing in colder climates, as frozen wastewater causes serious pump problems. Discharge lines should use drain fittings that allow for snaking if blockages occur later and should minimize sharp bends that catch debris. Professional installation ensures the pump matches system requirements and all components are appropriately sized. Remember that grinder pumps depend entirely on electrical power, so consider backup generator options for critical applications to prevent backups during outages.

A grinder pump clogged with debris doesn’t have to mean costly emergency repairs or sewage backups. By recognizing warning signs early, understanding the clog’s location and cause, and taking appropriate action—whether DIY float switch cleaning, professional discharge line clearing, or eventual replacement—you can restore proper function and protect your property. Most importantly, implementing strict usage guidelines and regular maintenance prevents future clogs from developing in the first place, saving money and frustration while extending your grinder pump’s lifespan. Remember that prevention is always more cost-effective than emergency repairs when it comes to your home’s wastewater system.