Nothing undermines your morning coffee ritual faster than a poorly assembled grinder delivering inconsistent, uneven grounds that ruin extraction. Whether you’re setting up a new conical burr grinder, reassembling your LIDO hand grinder after deep cleaning, or replacing the entire grinding assembly in a Gaggia espresso machine, proper coffee grinder assembly determines whether you’ll enjoy uniform particle size or frustrating inconsistencies in every brew. This comprehensive guide walks you through every major assembly scenario, from initial setup to troubleshooting common challenges that arise during reassembly—saving you time, money, and countless disappointing cups.

The assembly process varies significantly between manual hand grinders and electric units, but the underlying principles remain constant: proper alignment, correct torque application, and verification before final use. Coffee enthusiasts consistently report dramatic improvements in grind quality after learning to assemble and maintain their equipment properly. Beyond the technical aspects, understanding how your grinder comes together helps you diagnose issues faster, extend equipment lifespan, and make informed decisions about repairs versus replacements.

Pre-Assembly Workspace Organization Essentials

Create a dedicated workspace before touching any components to prevent frustrating mistakes during coffee grinder assembly. Start by gathering all necessary tools, including hex wrenches, screwdrivers, and manufacturer-provided adjustment tools. The hex tool included with LIDO grinders serves multiple purposes during both routine adjustment and complete disassembly—losing this tool creates significant inconvenience for future maintenance. Clear your area of coffee residue, oils, or debris that could contaminate internal components during assembly.

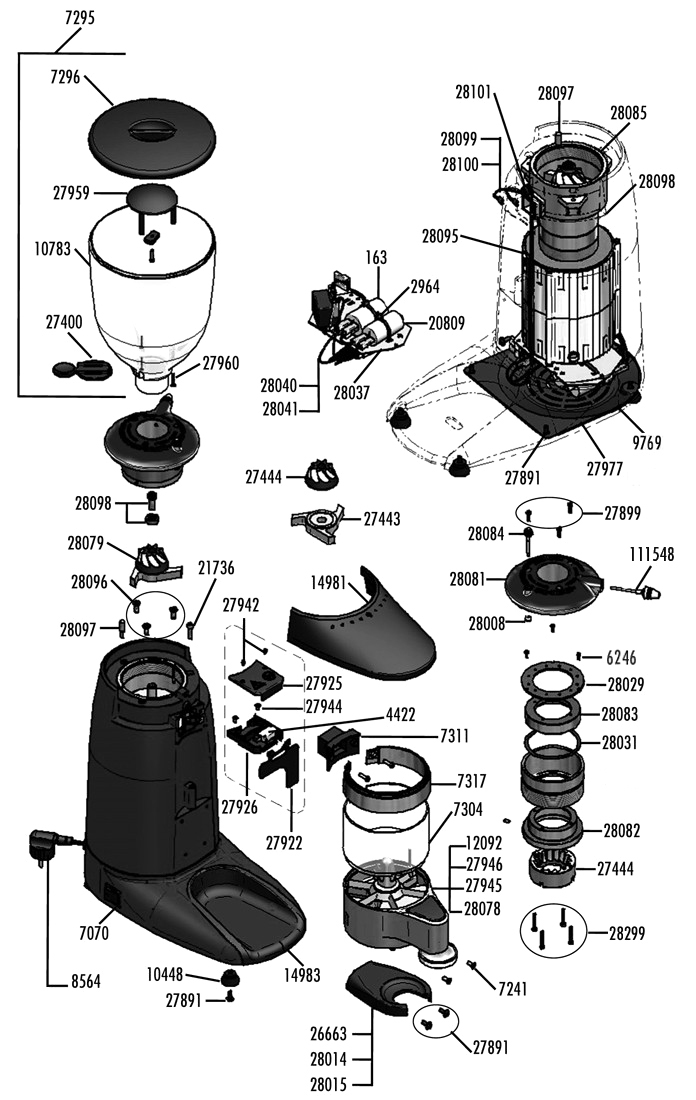

Inspect all components for shipping damage or manufacturing defects before assembly begins. For new grinders, examine burrs for debris, alignment pins for damage, and threading for smooth operation. If assembling a replacement part like the Gaggia complete grinder assembly, compare received components against official parts diagrams to verify completeness. Check that all included items match your machine model exactly—similar espresso machine generations often use incompatible components despite superficial similarities.

Place a white towel or clean mat on your workspace to provide visibility for small parts and prevent rolling components from disappearing. Have a small container ready for hardware such as screws and washers, as these small components easily roll away during the assembly process. Clean hands or gloves prevent transferring oils to burrs and other precision surfaces that affect grinding performance.

Conical Burr Grinder Component Alignment Sequence

Conical burr coffee grinders require precise component alignment during assembly to achieve consistent particle size distribution. Begin by positioning the lower burr carrier within the main housing, using alignment pins or guides to ensure correct positioning—never force the carrier if it doesn’t seat easily, as this indicates misalignment that will cause operational problems. The conical burr then seats onto the drive shaft, requiring verification that the drive flats or splines engage properly before proceeding.

The upper burr carrier connects to the adjustment mechanism next, with many designs allowing pre-assembly testing of the adjustment range before final tightening. Locking rings secure the assembly under tension necessary for maintaining grind settings during operation. Tighten these rings to manufacturer specifications using the appropriate tool to prevent overtightening, which can strip threads or crack components.

How to Verify Correct Burr Parallelism

Examine the burr surface for any debris or damage that could affect grinding consistency before final assembly. Rotate the adjustment mechanism through its full range to ensure smooth operation without binding or excessive play. Experienced users recommend verifying burr parallelism by placing a thin sheet of paper between the burrs and checking for even contact around the entire circumference. Uneven pressure indicates misalignment requiring correction before final tightening.

LIDO Hand Grinder Stuck Ring Release Techniques

The LIDO grinder series from Orphan Espresso presents unique assembly challenges that puzzle many new owners who immediately disassemble their grinder before ever using it. This behavior stands out in coffee enthusiast communities, as similar discussions rarely arise regarding other premium grinders like Versalab or Mythos units. The most common assembly obstacle involves lock and adjustment rings becoming stuck after disassembly.

Palm Pressure Method for Moderate Binding

For moderately stuck rings, the palm of your hand applied firmly around the ring circumference often provides sufficient force to break the bond. Position your hand flat against the ring and apply steady pressure while rotating counterclockwise. If this approach fails, wrap a clean rag around the ring for improved grip and try again before resorting to impact tools. This technique works effectively for most LIDO assemblies when performed immediately after cleaning.

Non-Metallic Impact Method for Severe Binding

When palm pressure proves insufficient, use a non-metallic mallet to apply controlled impacts around the ring circumference. Work methodically around the ring, delivering moderate taps rather than concentrated force in a single location. Wood blocks placed against the ring and struck with a mallet achieve similar results when dedicated rubber mallets aren’t available. Never use steel hammers or screwdrivers, as they can mar surfaces and create alignment issues.

Complete Espresso Machine Grinder Replacement Protocol

Super-automatic espresso machines like Gaggia Accademia and Saeco Xelsis utilize complete grinder assemblies that replace all major internal components in a single unit. This assembly approach simplifies repair procedures but requires careful verification before installation.

Essential Components Checklist Before Installation

Confirm your complete grinder assembly package contains all necessary elements: motor assembly providing rotational force, burr set for bean comminution, wiring harness for control system connection, sensor assembly for operational feedback, coffee chute for directing grounds, and rubber dampeners reducing vibration. Note that the coffee chute gasket often isn’t included and must be ordered separately if required.

Critical Compatibility Verification Steps

Before purchasing or installing, verify compatibility using official parts diagrams with manufacturer part number 11022036 or alternate number 996530007214. Component variations exist between similar machine generations, so a visual match doesn’t guarantee compatibility. Review the complete contents list carefully and compare against your machine’s requirements—these items are generally not eligible for return once opened.

Post-Assembly Grind Calibration Procedure

After any coffee grinder assembly or disassembly, grind settings require recalibration to achieve optimal results. The “zero” reference point for grind adjustment typically shifts during the process, necessitating systematic adjustment and testing.

Begin by setting the grinder to a medium-fine setting as a starting point, then grind a small amount of beans while observing the output. The adjustment mechanism should turn smoothly through its range without excessive play or binding. Any roughness indicates misalignment requiring correction before continued use.

Particle Size Distribution Assessment

Examine particle size distribution by rubbing a small amount of grounds between your fingers. Uneven particles, excessive fines (powder), or unusually large chunks indicate burr alignment problems. A properly assembled grinder produces consistent particle sizes with minimal variation. Perform a test brew to evaluate real-world performance after visual inspection confirms appropriate grind consistency.

Professional-Grade Assembly Tools You Need

Proper tool selection prevents component damage during coffee grinder assembly while reducing effort required for challenging procedures.

Must-Have Tools for Every Grinder Owner

Keep all manufacturer-provided tools in an accessible location for future maintenance needs. The hex tool included with LIDO grinders serves multiple purposes during both routine adjustment and complete disassembly. For stuck lock rings, rubber or poly mallets provide adequate force without risking component damage—wood blocks and clean rags serve as effective alternatives when dedicated mallets aren’t available.

Tool Maintenance Best Practices

Keep your tools clean and organized, as coffee residue on tool surfaces can transfer to internal components during assembly, potentially affecting performance. Precision screwdriver sets enable access to internal components on electric grinders, while adjustable wrenches handle larger fastening tasks. Document your maintenance schedule and any observations about tool condition for future reference.

Preventative Maintenance to Avoid Future Assembly Issues

Regular maintenance significantly reduces assembly challenges during future disassembly and reassembly cycles. Coffee oil residue accumulates progressively, and removing this residue before it polymerizes prevents the severe binding that makes subsequent disassembly difficult.

Clean the grinding assembly regularly according to manufacturer recommendations, using appropriate cleaning products that won’t damage components. Brush-based cleaning removes loose residue, while periodic deep cleaning with specialized solutions addresses accumulated oils. Always dry components completely before reassembly, as moisture can cause corrosion and affect lubricant performance.

Apply food-safe lubricant to threading and moving surfaces as recommended, being careful to avoid getting lubricant on burrs. A thin layer provides adequate protection without attracting excess coffee residue. Document your maintenance schedule and any observations about component condition, creating a reference that helps anticipate future maintenance needs.

By following these coffee grinder assembly guidelines, you’ll achieve proper setup for consistent grinding performance, extend equipment lifespan through correct maintenance procedures, and build confidence for handling future assembly challenges. Whether working with manual hand grinders or complex espresso machine assemblies, the principles of careful preparation, proper tool selection, and systematic verification lead to successful outcomes that transform your coffee experience from frustrating to flawless.