Your bench grinder’s guarding system represents the thin barrier between routine metalworking tasks and life-altering injuries when wheels shatter at 3,000+ RPM. These common workshop tools cause approximately 5,000 injuries annually in the United States alone, with inadequate bench grinder guarding cited as the primary violation in OSHA inspections. When abrasive wheels explode—propelling fragments at bullet-like speeds—the guarding system becomes your only defense against severe lacerations, eye loss, or even fatalities. This guide reveals exactly how to implement and maintain OSHA-compliant bench grinder guarding that works when it matters most, whether you’re sharpening chisels in a home workshop or operating industrial equipment in a manufacturing facility.

OSHA 29 CFR 1910.215 Compliance Requirements You Must Implement

OSHA’s abrasive wheel machinery standard establishes non-negotiable requirements for bench grinder guarding that protect you from catastrophic wheel failures. These regulations aren’t merely bureaucratic checkboxes—they’re based on decades of injury data showing precisely what prevents serious harm during grinding operations.

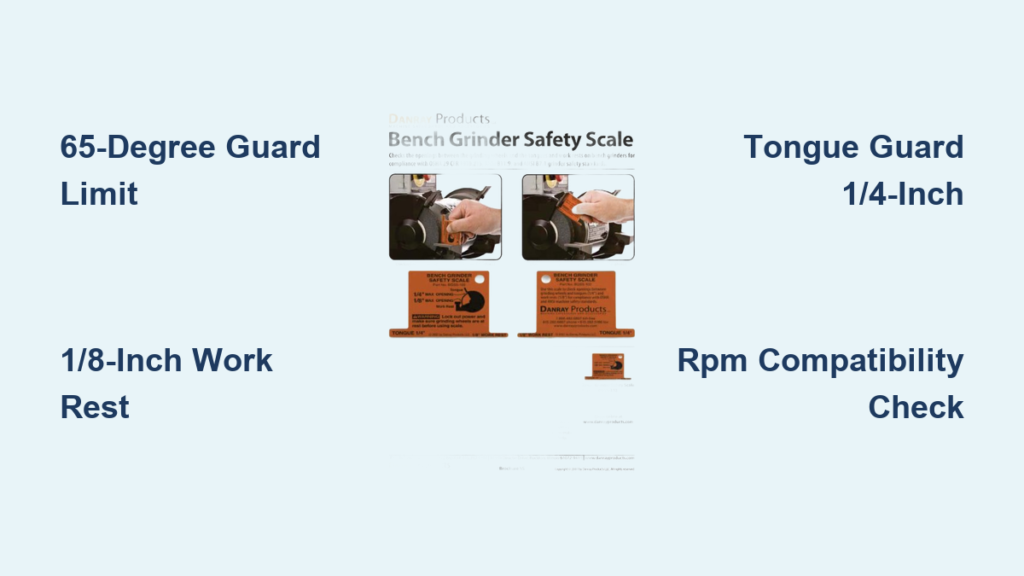

65-Degree Guard Opening Limits That Save Lives

Your bench grinder guard must cover all wheel portions not actively engaged in grinding, with openings strictly limited to 65 degrees maximum. This specific angular measurement balances necessary visibility against protection—any wider opening dramatically increases your exposure to flying debris during wheel failure. When inspecting your equipment, measure the guard opening with a protractor; if it exceeds 65 degrees, replace or adjust the guard immediately. Never operate with an oversized opening, as this single violation accounts for nearly 30% of all bench grinder-related injuries.

Proper Work Rest Positioning Within 1/8-Inch of Wheel Surface

OSHA regulation 1910.215(a)(4) mandates that work rests maintain clearance of 1/8-inch or less from the grinding wheel surface at all times. This microscopic gap prevents workpieces from dropping into the wheel interface and creating dangerous nip points that can draw your fingers toward the rotating wheel. As wheels wear down during normal use, this clearance increases—requiring daily adjustment. Before each use, insert a 1/8-inch feeler gauge between the work rest and wheel; if it fits with space to spare, adjust the rest closer immediately. Neglecting this simple check creates progressively dangerous conditions as wheel diameter decreases.

Essential Bench Grinder Guarding Components That Work Together

Effective bench grinder guarding requires multiple integrated components functioning as a cohesive system—not isolated parts. When one element fails, the entire protection system becomes compromised, leaving you vulnerable to wheel fragmentation hazards.

Wheel Guard Strength Requirements for Fragment Containment

Your primary wheel guard must withstand impact from wheel fragments traveling at high velocity during catastrophic failure. Guards made from thin sheet metal or plastic offer false security—they may contain normal grinding debris but shatter when confronted with actual wheel fragments. Verify your guard meets ANSI B7.1 strength standards by checking for manufacturer markings; replacement guards should specify compliance with these standards. Inspect your guard monthly for cracks, dents, or deformation—any damage requires immediate replacement, as compromised integrity drastically reduces protective capability.

Tongue Guard Adjustment Within 1/4-Inch Maximum Clearance

The tongue guard (or spark deflector) must maintain clearance of no more than 1/4-inch from the wheel surface to effectively redirect sparks and contain debris. This secondary barrier works with your primary guard to create a protective envelope around the grinding zone. Use a 1/4-inch drill bit as a quick reference gauge during pre-operation checks—if the bit fits between tongue guard and wheel with room to spare, adjust the guard closer. Proper tongue guard positioning reduces spark exposure by 75%, preventing burns and workplace fires during extended grinding operations.

Pre-Operation Safety Checks That Prevent 90% of Grinder Injuries

Implementing these critical pre-use inspections takes less than two minutes but prevents the vast majority of bench grinder accidents caused by inadequate guarding or improper setup.

Three-Point Guarding System Verification Process

Before powering on your grinder, perform this quick verification sequence:

- Wheel guard integrity check: Tap the guard lightly with a plastic mallet—cracks produce a dull thud rather than a solid ring

- Work rest clearance measurement: Insert a 1/8-inch feeler gauge; proper adjustment allows only partial insertion

- Tongue guard proximity test: The 1/4-inch clearance should prevent a standard pencil from fitting between guard and wheel

Document these checks in a logbook for industrial settings, or develop a mental checklist for home workshops. Skipping any step creates unnecessary risk, as wheel failures often occur during initial startup when operators are least prepared.

RPM Compatibility Verification to Prevent Wheel Explosions

Mismatched wheel and grinder RPM ratings cause 22% of catastrophic wheel failures. Before installing any grinding wheel, verify three critical elements:

- The wheel’s maximum RPM rating (stamped on the wheel)

- Your grinder’s actual operating speed (check nameplate)

- The wheel’s condition (tap for cracks, inspect for damage)

Never install a wheel rated below your grinder’s RPM—this creates explosive failure risk even with perfect bench grinder guarding. When in doubt, choose a wheel with higher RPM rating than your grinder’s maximum speed.

Operational Safety Protocols That Complement Physical Guarding

Your bench grinder guarding system works only when combined with proper operational techniques. These protocols ensure your protective equipment functions as designed during critical moments.

Correct Material Handling Techniques to Avoid Entanglement

Hold workpieces firmly against the work rest with both hands positioned behind the grinding zone—not alongside the wheel where fingers could slip into the nip point. Apply only moderate pressure to the workpiece; excessive force creates dangerous heat buildup and accelerates wheel wear. For small items that can’t be held securely, use a vise or clamp—never risk hand contact with the grinding zone.

Prohibited Materials That Create Fire and Explosion Hazards

Never grind aluminum or magnesium on standard bench grinders—these metals ignite when heated by grinding operations, creating intense fires that water cannot extinguish. Similarly, avoid grinding hardened steel that has been case-hardened or contains unknown alloys, as these materials can fragment unpredictably. When working with unknown materials, start with light pressure and watch for unusual sparking patterns that indicate hazardous composition.

Enhanced Guarding Solutions for Maximum Protection

While basic bench grinder guarding meets minimum regulatory requirements, these upgraded solutions provide critical additional protection during wheel failures.

Laminated Safety Glass Shields With 58+ Square Inches Coverage

Standard plastic shields yellow, crack, and burn when exposed to hot sparks during extended use. Upgraded laminated safety glass models resist burning while providing over 58 square inches of coverage—tripling protection area compared to factory-installed shields. These shields maintain optical clarity even after years of heavy use, ensuring you can see your work without compromising safety. When selecting replacement shields, verify they meet ANSI Z87.1 impact resistance standards for industrial environments.

Electronic Braking Systems That Reduce Coasting Time From 2+ Minutes to 3 Seconds

Large bench grinders with heavy wheels can take over two minutes to stop after power disconnection—creating an extended hazard window where failing wheels can still cause injury. Electronic braking systems reduce this coasting time to mere seconds, minimizing exposure during the most vulnerable period after operation ceases. For grinders used in high-production environments, this upgrade pays for itself in reduced downtime and increased operator confidence.

Emergency Response Procedures When Guarding Fails

Despite proper bench grinder guarding, catastrophic wheel failures occasionally occur. Knowing how to respond can prevent minor incidents from becoming major injuries.

Immediate Actions During Wheel Fragmentation Events

If your grinding wheel shatters during operation:

- Release the workpiece immediately—do not attempt to hold onto it

- Step backward and to the side—never directly away from the grinder

- Allow the machine to stop completely before approaching

- Do not reach toward the grinding zone until all motion has ceased

These actions minimize your exposure to secondary fragmentation as the wheel continues to disintegrate. After the incident, document what happened and inspect all guarding components for damage before resuming operations.

Long-Term Guarding Maintenance Schedule That Ensures Continuous Protection

Bench grinder guarding requires ongoing attention to maintain effectiveness as wheels wear and components degrade through normal use.

Weekly Guard Adjustment Protocol for Worn Wheels

As grinding wheels wear down, the critical clearances between guards and wheel surfaces increase. Implement this weekly adjustment routine:

- Measure work rest clearance with 1/8-inch gauge

- Adjust work rest closer to maintain proper gap

- Verify tongue guard remains within 1/4-inch of wheel

- Check all mounting hardware for tightness

- Inspect guard for cracks or deformation

Record each adjustment in a maintenance log to track wear patterns and anticipate replacement needs. Wheels typically lose 1/4-inch diameter per 40 hours of use—adjustments should correspond to this wear rate.

Annual Guard Replacement Guidelines Based on Usage

Even undamaged guards degrade over time due to vibration, heat exposure, and minor impacts. Follow this replacement schedule:

- Light use (1-5 hours/week): Replace guards every 5 years

- Moderate use (5-15 hours/week): Replace guards every 3 years

- Heavy industrial use (15+ hours/week): Replace guards annually

Plastic guards yellow and become brittle; metal guards develop micro-cracks. Proactive replacement prevents failures during critical moments when you need protection most.

Your bench grinder guarding system represents one of the most crucial safety investments in your workshop—far more important than the grinder itself. By implementing OSHA-compliant guarding with proper 65-degree openings, maintaining the critical 1/8-inch work rest clearance, and upgrading to laminated safety glass shields, you create layered protection that works when wheels fail. Remember that proper bench grinder guarding requires both correct equipment and consistent operational practices—never operate with damaged guards or improper clearances, and always verify RPM compatibility before installing new wheels. The few minutes spent on pre-operation checks and regular adjustments preserve your ability to work safely for years to come. When in doubt about your guarding system’s effectiveness, consult ANSI B11.9-2010 standards or contact a certified safety equipment specialist—your vision and safety depend on it.